The device developed by a group of doctors and engineers from VinUni University is like a telescope that helps knee replacement achieve precise results, at a cost of only 1/10 compared to similar products in the world.

Dr. Pham Trung Hieu and his colleagues at the VinUni 3D Lab Group, the Center for 3D Technology Research in Medicine, VinUni University, have successfully developed a personalized surgical navigation device (PSI) that can orient the position of joint replacement surgery with up to 98% accuracy. The research has just won the Second Prize at the 2023 Science Initiative organized by VnExpress .

The device helps surgeons perform bone cuts during surgery according to the programming plan, helping to increase the accuracy of artificial joint placement to optimize the effectiveness and safety of surgery for patients. In Vietnam, there has never been any research on the application of PSI in joint replacement surgery.

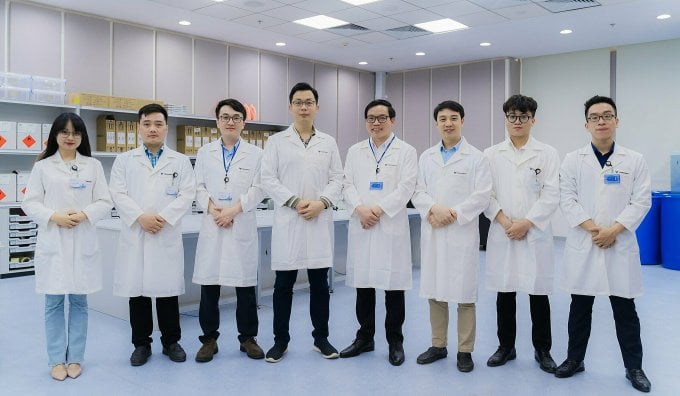

BSCK II Pham Trung Hieu was awarded second prize for his product of a surgical guidance device for knee replacement. Photo: Giang Huy

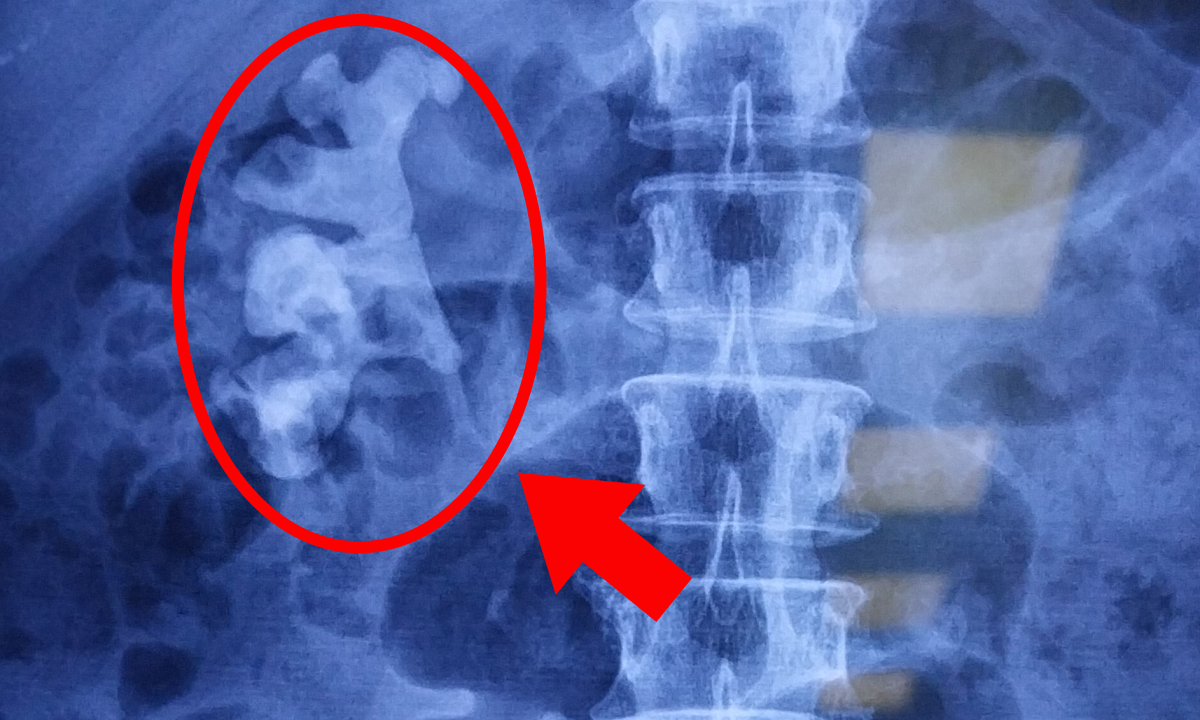

Dr. Hieu said that when performing surgeries to treat and reconstruct damaged bone and joint structures, it is necessary to have the support of high-precision guidance aids, because the bone and joint system is a complex dynamic balance system in 3D space. Placing the artificial joint in an incorrect optimal position can lead to changes in the body's axis of motion, affecting post-operative mobility, as well as causing prolonged pain or reducing the lifespan of the artificial joint in the body.

Artificial joints and accompanying guidance devices are currently imported and designed to fit the European and American body. The mismatch between the Vietnamese bone structure and these instruments can also affect the precise placement of the implants, reducing the effectiveness of treatment, and can even lead to complications if the surgeon is not experienced.

Using other positioning systems such as Robot or Navigation is often too complicated, prolongs the surgery time and requires extremely expensive investment costs, not really suitable for the conditions of the majority of the population in Vietnam.

"The team developed the idea of a personalized surgical guidance device printed with biocompatible 3D materials that can safely contact the patient's tissue, achieving accuracy and safety compared to currently available devices at a lower production cost," said Dr. Hieu.

Personalized surgical guidance device in total knee replacement surgery. Photo: Center for 3D Technology in Medicine, VinUni University

The team spent more than a year calculating the optimal designs and testing hundreds of prototypes before creating the final PSI product. These designs were made based on bone structure data, scanned from CT or MRI scans, and molded to fit the exact bone positions of each patient.

Thanks to this device, the surgeon only needs to clearly expose the area to be operated on and use about 2-3 small 3D printed devices to accurately determine the position of each bone slice. Previously, the surgeon had to use about 30 mechanical tools to help locate indirectly in a complex way through other landmarks on the limb.

In addition, in this study, the team also used 3D printing technology to print models of the patient's own knee joints. The printed anatomical models help surgeons use surgical guidance devices to conduct formal preoperative simulations, as well as help train young doctors who are starting to learn about joint replacement.

Thus, for each case, the doctors perform surgery twice. Before surgery, they will do it on an anatomical model combined with a guiding aid, then perform the actual surgery on the patient with the designed PSI cutting tray.

The entire process from receiving information to completing the finished cutting mold takes only an average of 3 days (at the earliest 2 days) with a cost of only 1/10 compared to similar products in the world.

The team has successfully performed nearly 50 total knee replacements as well as 40 hip replacements and hundreds of other joint replacements and bone alignments using 3D printing technology for personalized surgical guidance devices at the Vinmec healthcare system. This technology is also applied to create nose molds for children with cleft palates, anatomical models to help personalize interventional stents for complex cardiovascular diseases or 3D titanium patch molds for skull bone defects...

A group of doctors and engineers from the Center for 3D Technology Research in Medicine, VinUni University. Photo: NVCC

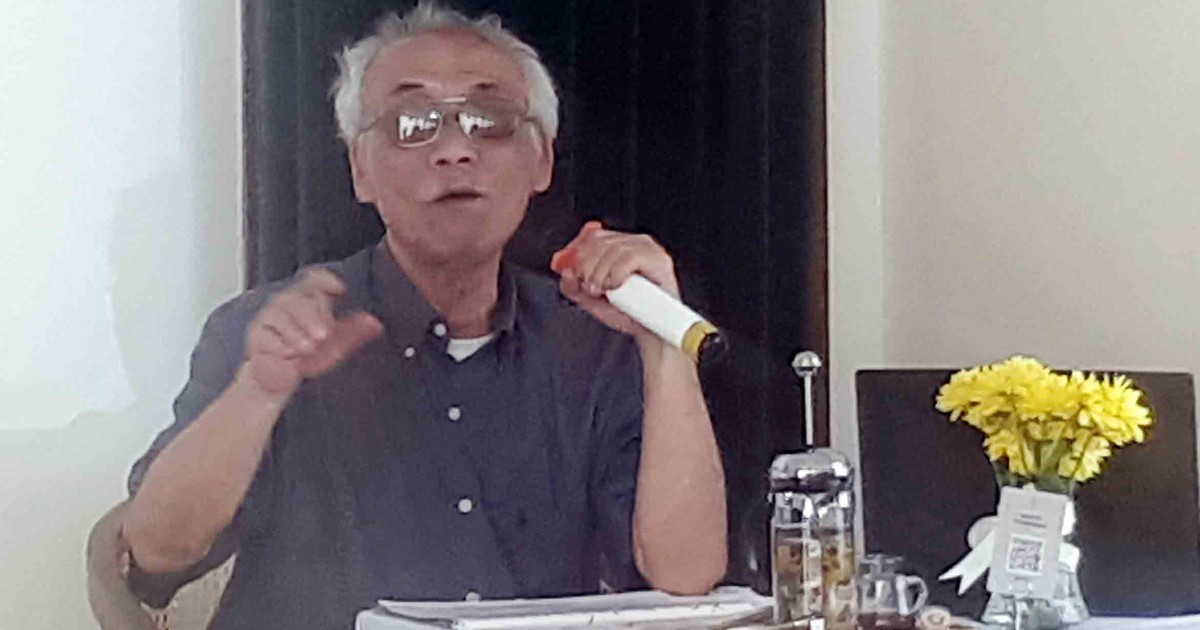

Sharing with VnExpress, Professor, Doctor Tran Trung Dung, Director of the Center for Orthopedics and Sports Medicine, Vinmec Healthcare System, said that personalized treatment in medicine is a world trend, in which the development of surgical guidance devices will contribute to optimizing surgical efficiency. Previously, an experienced surgeon could achieve the desired maximum accuracy for surgery of about 90%, but with surgical guidance devices, the accuracy can approach 98%. "Navigation technology is like a "viewfinder" that can help improve accuracy, playing an important role in increasing the success rate of surgery," said Professor Dung.

The solution of Dr. Hieu's team and VinUni 3D Lab was highly appreciated by Professor Dung because the new technology helps create "drawings" with parameters suitable for the patient's natural anatomical parameters with precision for each individual, thereby shortening the time of surgery. "3D printing technology to create personalized cutting molds also has the meaning of standardization, helping to create products that can be put into mass production suitable for the characteristics of Vietnamese people in the near future," he said.

He added that the application of surgical guidance devices in units around the world currently takes about 3-6 weeks to produce, costing about 3,000 USD. But with the new 3D printing technology, the time is reduced to only about 2 days, with a cost of only a few million VND. Professor Dung hopes that in the next phase, VinUni 3D Lab will standardize its products in many other surgical applications, to help doctors improve surgical efficiency, and at the same time, hope to help more patients in the country benefit from advanced science and technology in the world.

Sharing his joy after the award ceremony, Dr. Hieu said that this was a playground for the team to exchange and learn from each other, introduce products, and at the same time, the judges with high professional qualifications gave their opinions to help improve the product further. "I hope that the product will be brought to many users, especially patients who have to undergo joint replacement surgery and orthopedic trauma, there will be a superior improved product with a more suitable cost," he said.

In its second year, VnExpress's 2023 Science Initiative Contest hopes to create a playground for those who love science and technology; targeting professional and non-professional scientists under 40 years old, to seek initiatives, solutions, and connections to accelerate the application of advances in science and technology.

Nhu Quynh

Source link

Comment (0)