Although not directly dedicating their lives to the sea, Phan Thanh Thiem (born in 1978) and Phan Thanh Minh (born in 1982) in My Thuy village, Hai An commune, Hai Lang district chose the profession of making shrimp paste and building traditional boats to indirectly connect with the sea. And Phan Thanh Thiem and Phan Thanh Minh, with their shrimp paste and composite boats, are contributing to making the traditional profession famous in the coastal area.

Fishermen in coastal areas buy mackerel to make fish sauce - Photo: SH

Now, Mr. Phan Thanh Thiem has officially “inherited” the profession of making shrimp paste from his mother (Mrs. Vo Thi Thoi has passed away). Mr. Thiem did not hesitate to “reveal” to me the recipe for making a drop of fish sauce that is amber in color, delicious, when tasted, the salty taste on the tip of the tongue and leaves a sweet taste in the throat. According to Mr. Thiem, to make delicious fish sauce, you must pay attention to the selection of ingredients and he often uses mackerel, duoi, charcoal rice...

Once the ingredients have been selected, it is time to marinate the fish with salt (depending on the type of fish to have a certain marinating ratio). For example, for anchovies, charcoal rice... mix 1 kg of salt with 5 - 6 kg of fish; for mackerel, the ratio is 1 kg of salt mixed with 3 - 4 kg of fish. In the process of making fish sauce, mixing fish is the most important step and the ratio of fish - salt must be ensured to be neither too salty nor too bland.

If the fish is too salty, it will hydrolyze slowly, and the finished product, the fish sauce, will not be delicious; on the contrary, if it is too bland, the fish sauce will spoil quickly and change color. After salting the fish, put it in a jar or tank... sprinkle a thick layer of salt on the surface and then press it down to help the fish cook quickly and ensure hygiene. Keep the salted fish for about 7 months to 1 year until the fish is cooked, then filter it into fish sauce.

Filtering fish sauce must also be done at the right time and often at night to avoid flies and mosquitoes. Filtering tools as well as bottling and labeling must always be clean and hygienic...

As for the “secret” to making a jar of thick and delicious shrimp paste, it is from November of the previous year until April (lunar calendar) of the following year, when the shrimp paste drifts ashore with the waves offshore. Fishermen in the coastal areas start walking along the shore, observing with their naked eyes the clear blue water gradually turning dark red, with bubbles bubbling on the surface of the water, then they will definitely encounter a large school of shrimp paste.

Fishermen will quickly use a gold bar to catch sea shrimp by hand. At that time, fish sauce and shrimp workers like Mr. Thiem will go directly to the shore to buy. After purchasing the shrimp from fishermen, it will be washed and mixed with salt (ratio of 6 buckets of fresh shrimp mixed with 1 bucket of salt (salty shrimp); 12 buckets of fresh shrimp mixed with 1 bucket of salt (light shrimp) for about 24 hours, then scoop out the shrimp residue separately, leaving the red shrimp brine.

The shrimp residue is taken out and dried in the sun for about a day, then put into a mortar and pounded finely (the finer the pounding, the thicker the shrimp will be), mixed with the shrimp brine, stirred well, then put into a jar or pot and continue to dry in the sun for about half a month until it starts to ripen. The more the shrimp is exposed to the sun, the more fragrant it will be.

Mr. Thiem said that during the recent Lunar New Year 2025, Thanh Thuy Fish Sauce Production and Processing Facility sold more than 3,000 liters of fish sauce to the market. In 2024, Thanh Thuy Fish Sauce Production and Processing Facility sold more than 10,000 liters of delicious fish sauce to the market in the province and provinces such as Quang Binh, Hue City, and Ho Chi Minh City.

Afternoon. I sat with Mr. Phan Thanh Minh on the beach just to watch the small capacity composite boats dodging the waves to the shore after a day of fishing. Those composite boats, as I know, were made by Mr. Phan Thanh Minh himself with all his heart and love for the ocean.

Mr. Minh recalls that the coastal area of Hai An commune, Hai Khe, Hai Lang district originally did not have river mouths or inlets to buy large ships and boats for offshore fishing, so since ancient times, people have "anchored" their lives to bamboo boats to go out to sea and into the sea. And the craft of building bamboo boats was also born in the coastal area and has been shaped and developed until now. As for Mr. Minh, since childhood, he has followed his father through the sun and rain along the coastal areas of Quang Binh, Quang Tri, and Hue city to build and convert bamboo boats for fishermen.

Having been taught the craft by his father, a talented bamboo boat builder, along with his natural talent and aptitude, Mr. Minh gradually became one of the young boat builders who are highly skilled in the region and even in the coastal areas of neighboring provinces. Mr. Minh is also famous because the bamboo boats he makes by himself are always durable, neat, beautiful, have a long service life and are especially lighter than boats from other workshops by almost half.

According to Mr. Minh, the most important part of building a bamboo boat is preparing the materials. Once all the materials are available, it only takes about 12-15 days to complete a bamboo boat. The wood, planks, and bamboo used to build the bamboo boat must be of good quality, old bamboo, mainly jackfruit wood, mu u, cho wood, kien kien and old bamboo to be able to withstand the rain and sun as well as the corrosion of sea water.

Once all the materials are prepared, it is time to build the boat (the boat is two long wooden bars bent at the head and tail of the boat down to the bottom of the boat). Once the boat is built, it is time to build the bevel (the stage of pressing two long, thick wooden bars about 3-4 cm, about 40 cm wide into the two ends of the bevel to create the boat's side). Of all the stages, the bevel is the most difficult stage, requiring a good bamboo boat builder to understand the structure, age of the wood... to press the hard wooden bars, creating the shape of the boat.

When the stage of making the boat is completed, the boat's ribs are shaped, and the boat's skeleton is shaped. And now the craftsman starts the stage of weaving bamboo strips to press them onto the side of the boat. The bamboo strips are woven into panels (about 0.5 cm thick) and then pressed onto the side of the boat (this stage is called "ap khau" by those in the profession). Once the "ap khau" stage is complete, the craftsman will use a layer of cow dung to cover the bamboo strips, and when it dries, he will continue to cover the layer of asphalt on top of the dung.

By doing so, the boat's rafters will be durable and resistant to seawater corrosion (the life of a boat's rafters is about 7-9 years before the owner replaces them with new ones). The final step to complete a bamboo boat is the "cong - giang - da" step.

“Cong” is a long wooden beam placed along the bottom of the boat to make the boat more sturdy lengthwise. “Giang” is many short wooden beams placed along the side of the boat to make the boat more sturdy lengthwise. “Da” is a wooden beam used to connect the two ends of the belvedere together. On average, each bamboo boat usually has 5 giang beams and 5 da beams.

The “cong-giang-da” stage is usually carried out after the asphalt layer covering the boat’s ribs has dried. After completing the “cong-giang-da” stage, the boat builder will draw “eyes” on the front of the boat. According to our ancestors, the “eyes” of the boat are a symbol to ward off sea monsters, evil spirits... and help the boat owner catch more shrimp and fish...

By 2022, the craft of building bamboo boats is no longer in its "golden age" and fishermen in coastal areas have started using composite boats instead of traditional bamboo boats. Mr. Minh continues to learn the craft of covering traditional bamboo boats with composite. Boats made from composite materials have many advantages and advantages over traditional bamboo boats.

The first advantage is that composite boats use very little wood, planks, old bamboo... so they are environmentally friendly, lighter than traditional bamboo boats, so when an engine is attached, the boat will have a speed many times higher; due to the use of composite materials, when at sea for a long time, composite boats are not waterproof, making the boat heavier, making fishermen have to work hard and get tired when bringing the boat ashore after each trip...

From 2022 to now, Mr. Minh has personally built nearly 300 large and small composite boats to sell to fishermen in the coastal areas of Quang Tri province and Hue city. The price of building a new composite boat ranges from 20 - 100 million VND/boat (depending on the size of the boat). Converting a traditional bamboo boat to a composite boat costs about 10 - 17 million VND/boat.

Sy Hoang

Source: https://baoquangtri.vn/rang-danh-nghe-truyen-thong-192319.htm

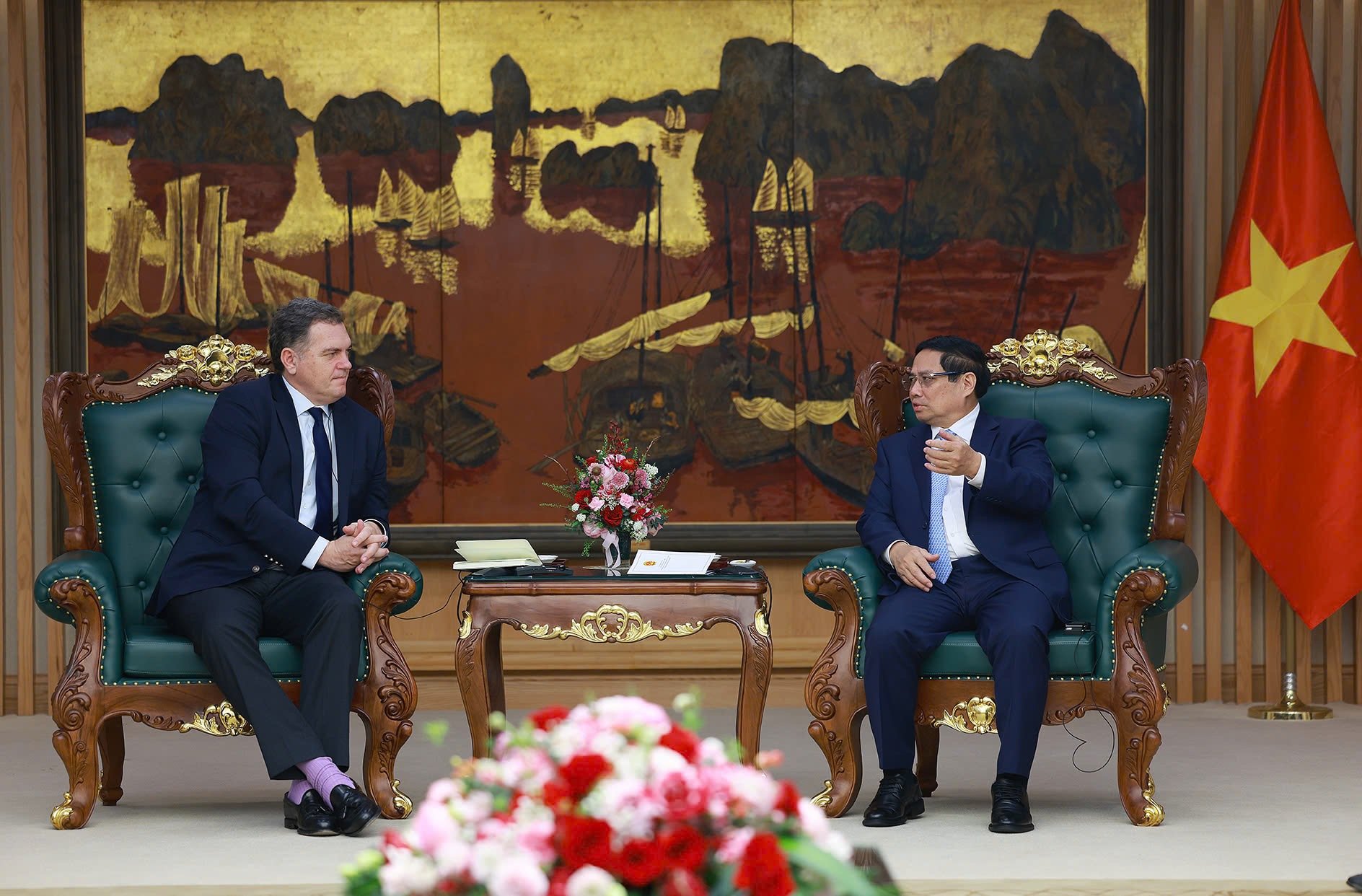

![[Photo] Prime Minister Pham Minh Chinh receives the head of the Republic of Tatarstan, Russian Federation](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/21/7877cb55fc794acdb7925c4cf893c5a1)

![[Photo] Overview of the Workshop "Removing policy shortcomings to promote the role of the private economy in the Vietnamese economy"](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/21/d1c58c1df227467b8b33d9230d4a7342)

![[Photo] Prime Minister Pham Minh Chinh receives French Minister in charge of Transport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/21/aa649691f85546d59c3624b1821ab6e2)

![[Photo] Meet the pilots of the Victory Squadron](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/21/fd30103acbd744b89568ca707378d532)

Comment (0)