Mechanical products are currently on the rise, however, challenges and competitiveness are still urgent issues that need to be solved.

Not developed properly

According to a report by the Vietnam Association of Mechanical Industry (VAMI), the country has about 3,100 mechanical engineering enterprises with 53,000 production facilities. Domestically produced mechanical products currently account for only about 7% of the market.

Mr. Dao Phan Long - former Chairman of the Vietnam Association of Mechanical Enterprises - said that according to statistics from the Center for Forecasting Human Resources Demand and Labor Market Information of Ho Chi Minh City in the period of 2022 - 2026, mechanical engineering is still one of the four key industries. Because not only creating machinery and equipment, the mechanical industry also promotes production in other industries such as automobiles, electronics, construction and agriculture. Vietnam's mechanical industry currently contributes about 16 - 17% of the country's GDP, while providing jobs for millions of workers.

However, the expert pointed out that currently, the Vietnamese mechanical industry still faces many major challenges. One of the top difficulties is the low level of technology and labor productivity. Many domestic mechanical enterprises mainly focus on simple processing and assembly instead of developing products with high added value. This leads to a large dependence on imported technology and raw materials.

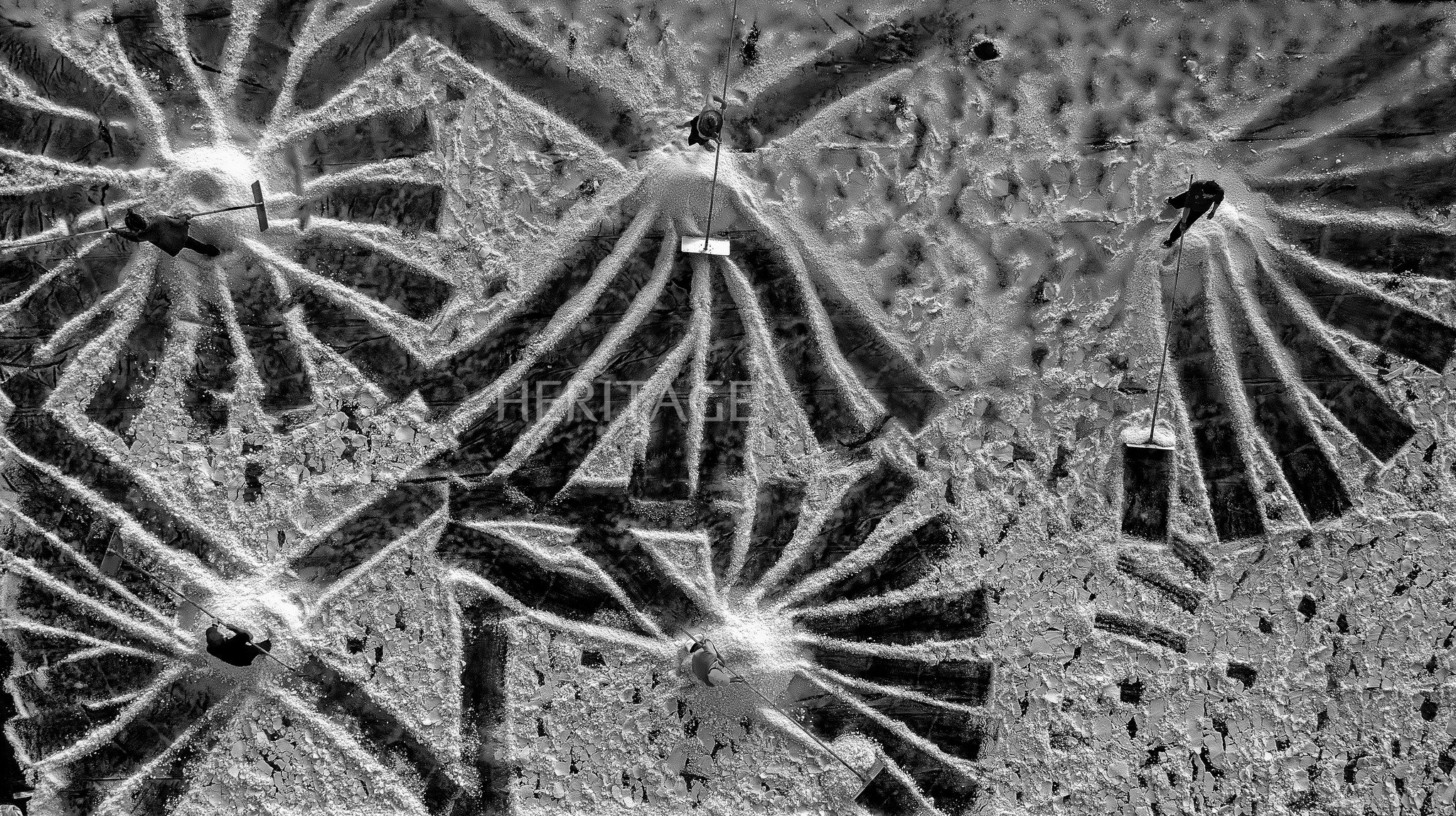

|

| One of the challenges is that the mechanical industry has not yet developed to its full potential, making the domestic supply chain incomplete. Photo: ST |

Mr. Cao Van Hung - Director of International Market Development, Smart Vietnam Precision Mechanical Joint Stock Company - pointed out the obstacles that mechanical enterprises are currently facing, especially in promoting production and business activities, aiming for export. Accordingly, one of the current challenges for the industry is that it has not developed to its full potential, making the domestic supply chain incomplete. "The lack of domestic raw materials and components forces enterprises to import from abroad, increasing production costs and reducing the competitiveness of Vietnamese mechanical products. At the same time, there is a lack of large, international mechanical enterprises playing a leading role" - Mr. Hung stated.

According to Mr. Hung, the research and development (R&D) capacity in the Vietnamese mechanical industry is still limited. Many businesses do not have enough resources or do not pay attention to investing in R&D, which reduces the ability to innovate and develop new technologies, affecting competitiveness in the international market.

In addition, the 4.0 industrial revolution has a strong impact on the mechanical engineering industry. Meanwhile, the level of mechanical engineering, especially precision engineering - the pillar of industrial production - is still backward compared to many countries. Many businesses face many challenges in improving technology, keeping up with trends, improving labor skills, infrastructure quality, etc., to be able to participate in the global supply chain and great competitive pressure from countries in the region as well as around the world.

Creating momentum to promote industries that manufacture and assemble finished products

Accordingly, to develop mechanical products in Vietnam, over the years, the Government and businesses have also made efforts to find solutions for this industry.

Specifically, Decision No. 319/QD-TTg of the Prime Minister on the mechanical industry by 2025, with a vision to 2035, is that by 2025 the mechanical industry will be developed with most of the majors having advanced technology, product quality meeting international standards, participating more deeply in global value; by 2030, it will reach 40% of the total output of the mechanical industry, by 2035, it will reach 45% of the total output of the mechanical industry.

To improve the competitiveness of the industry, many experts expressed that mechanical enterprises need more incentive mechanisms; in which, priority should be given to the use of domestic goods for domestic economic and investment projects. For example, priority should be given to domestically produced products; products that domestic enterprises can produce and produce well should be given priority for projects, and imports should be limited.

Sharing more, the representative of Hanoi Mechanical Company said that the Ministry of Industry and Trade needs to shape domestic enterprises to be able to meet and divide the market to have the opportunity to supply products to the domestic market. Then, boldly invest in new equipment and technology to reduce production costs and compete to participate in the supply chain.

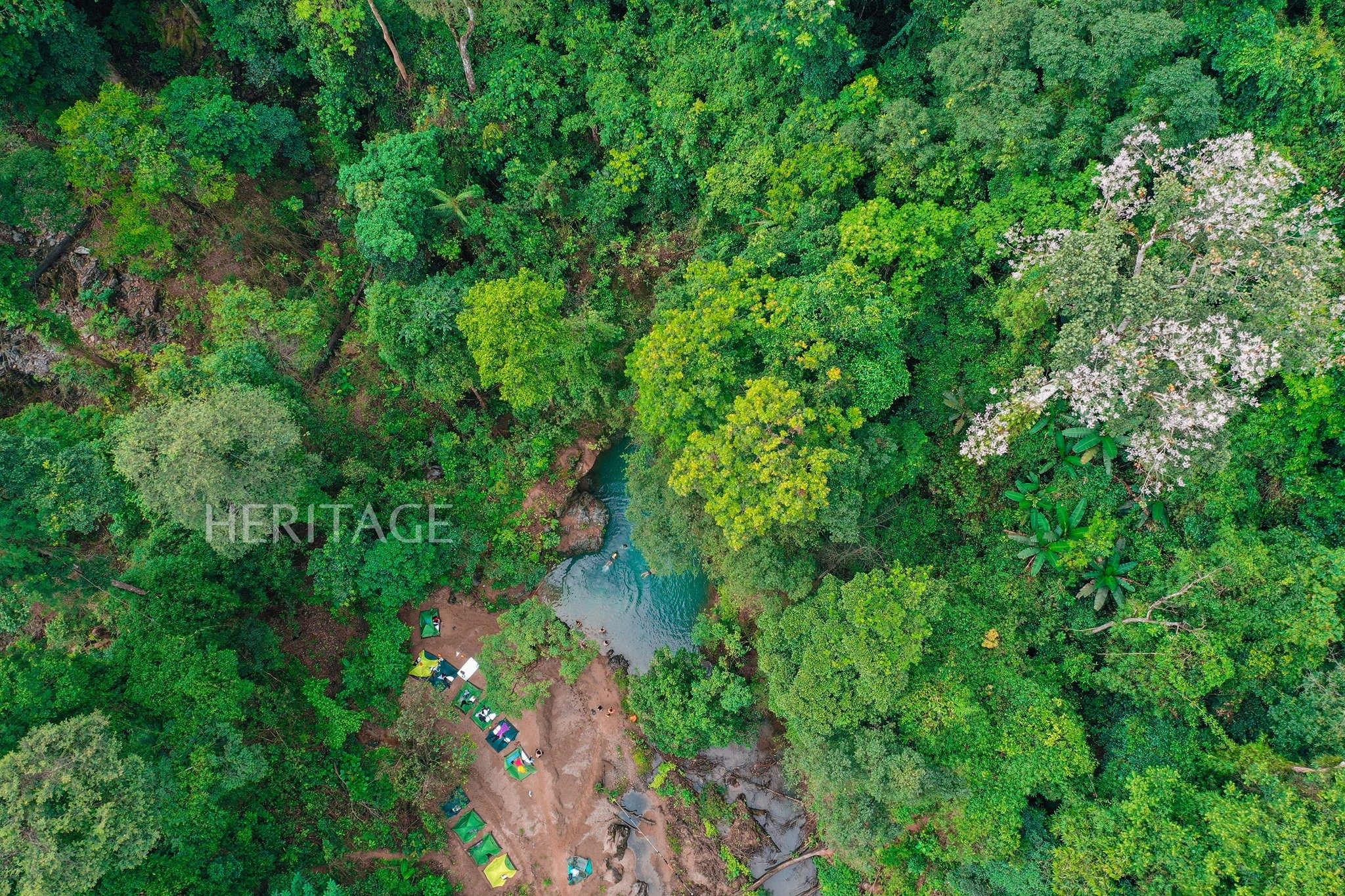

|

| To truly develop sustainably, the Vietnamese mechanical industry needs to continue promoting technological innovation, investing in R&D and strengthening international cooperation. Photo: D.N |

Mechanical enterprises also hope that the Ministry of Industry and Trade will advise the Government to soon develop strategies and plans to develop the mechanical industry as soon as possible. Along with that, it is necessary to soon issue support mechanisms and policies so that enterprises have the opportunity to access, expand cooperation and share the market, bringing about sustainable development.

In particular, to develop the mechanical industry in general and the mechanical support industry in particular, the State needs to have an output support program by connecting with potential buyers. Incentives for medium-sized supporting industry enterprises to invest in expanding production, training human resources, financial support... At the same time, create many orders, including orders for supporting industrial products for Vietnamese mechanical enterprises, especially for public investment projects.

Assessing the prospects, experts said that with efforts to improve and support from the government, the Vietnamese mechanical industry has many opportunities to develop strongly in the coming time. In particular, free trade agreements (FTAs) such as EVFTA and CPTPP have opened up great opportunities for Vietnamese mechanical enterprises to access international markets.

However, to truly develop sustainably, the Vietnamese mechanical industry needs to continue to promote technological innovation, invest in R&D and strengthen international cooperation. Only then can the mechanical industry make a greater contribution to the country's industrial and economic development in the future.

On the side of the Ministry of Industry and Trade, according to the representative of the Department of Industry, in the coming time, it will continue to strongly develop downstream industries, including a number of industries such as the energy industry, precision mechanical industries as well as a number of mechanical manufacturing industries, etc.

From there, it ensures that supporting industries have conditions to develop, creating momentum to promote industries that manufacture and assemble finished products, forming a market for domestic supporting industries to maintain and expand. That is the premise for domestic mechanical enterprises to become suppliers, participating deeply in the supply chain of corporations that manufacture and assemble final products.

Source: https://congthuong.vn/nang-cao-nang-luc-canh-tranh-cua-san-pham-co-khi-tiep-can-thi-truong-tiem-nang-358213.html

Comment (0)