According to TechSpot , scientists at the Faculty of Applied Science and Engineering at the University of Toronto (Canada) have applied machine learning algorithms to create nanomaterials that are highly durable but lightweight. This technology has the potential to have a strong impact on fields such as automobiles, aviation and space.

The team, led by Professor Tobin Filleter, designed special nanostructures that are just a few hundred nanometers in size – so small that more than 100 units stacked side by side would be needed to reach the thickness of a human hair. These materials are made up of tiny repeating blocks, allowing for flexible customization of properties.

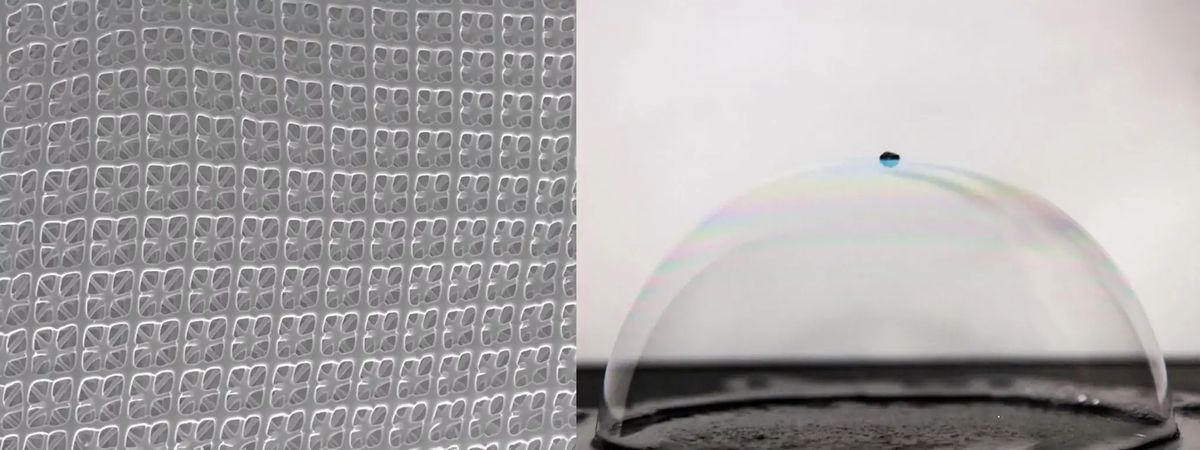

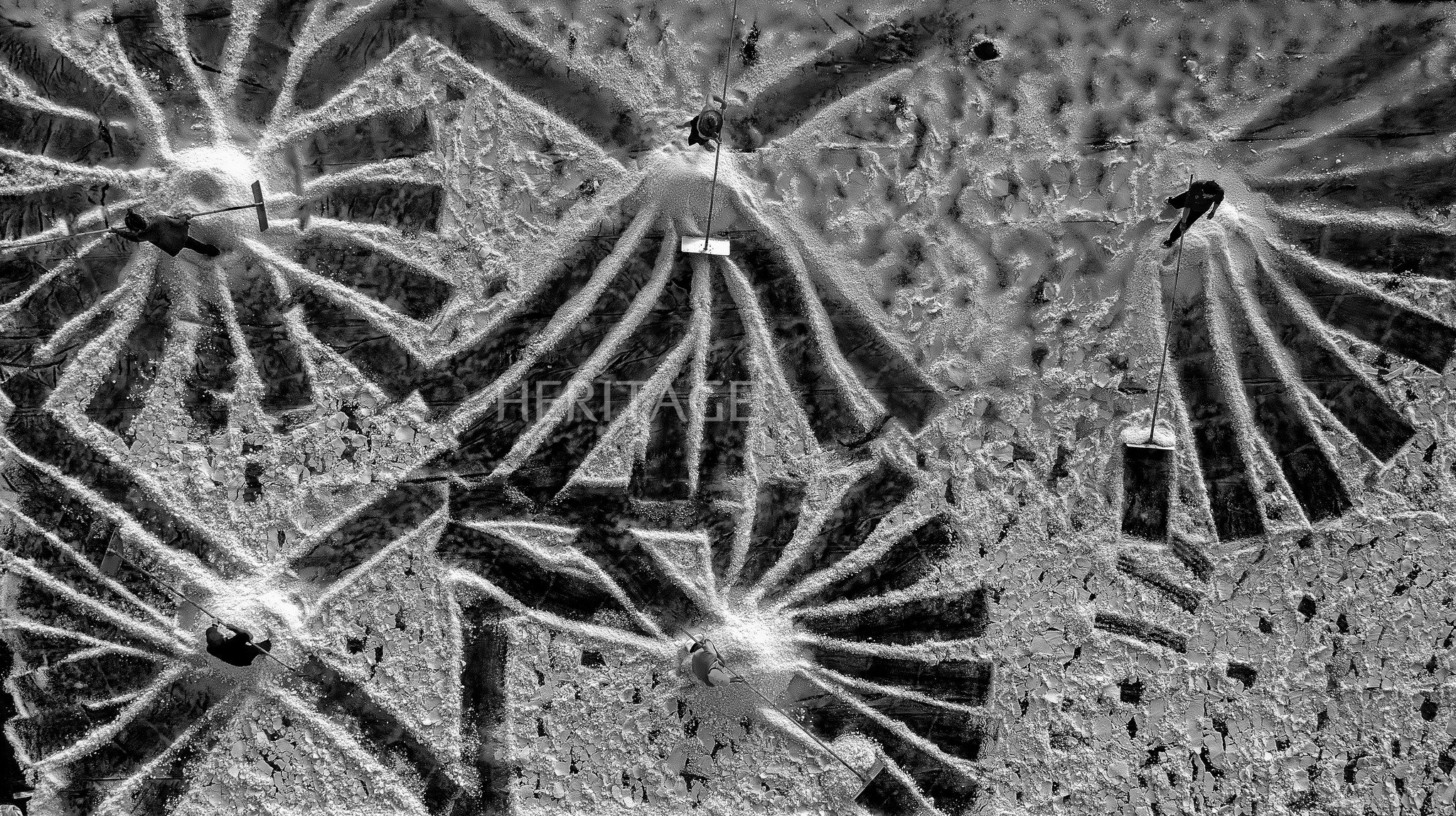

The ultimate nanomaterial, printed using two-photon 3D technology, is five times stronger than titanium but so light it floats on a bubble

PHOTO: UOFT ENGINEERING NEWS

This is the first time artificial intelligence (AI) has been used to optimize nanomaterials with complex architectures. According to Peter Serles, lead author of the study published in the journal Advanced Materials , the algorithm not only reproduces existing structures but also learns from changes in shape to predict new structures more efficiently.

The team used a two-photon 3D printer to create material prototypes, successfully fabricating optimized carbon nanolattices at the micro- and nanoscale. These designs are more than twice as strong as previous models, withstanding up to 2.03 megapascals of stress per cubic meter of material, about five times stronger than titanium.

The potential applications for this material are wide-ranging. Professor Filleter believes that the aviation industry could use them to produce ultra-lightweight parts for planes, helicopters and spacecraft. The research team estimates that replacing titanium parts on aircraft with the new material could save about 80 liters of fuel per year for every kilogram of material replaced, contributing to a significant reduction in carbon emissions from the aviation industry.

The project combines fields from materials science, machine learning, chemistry to mechanics, with the participation of partners from Karlsruhe Institute of Technology (Germany), MIT and Rice University (USA). In the future, the research team will continue to scale up production and test new material matrices to reduce weight while maintaining high strength and stiffness.

Source: https://thanhnien.vn/vat-lieu-nano-moi-duoc-phat-trien-nho-ai-nhe-va-ben-hon-ca-titan-185250208091930271.htm

Comment (0)