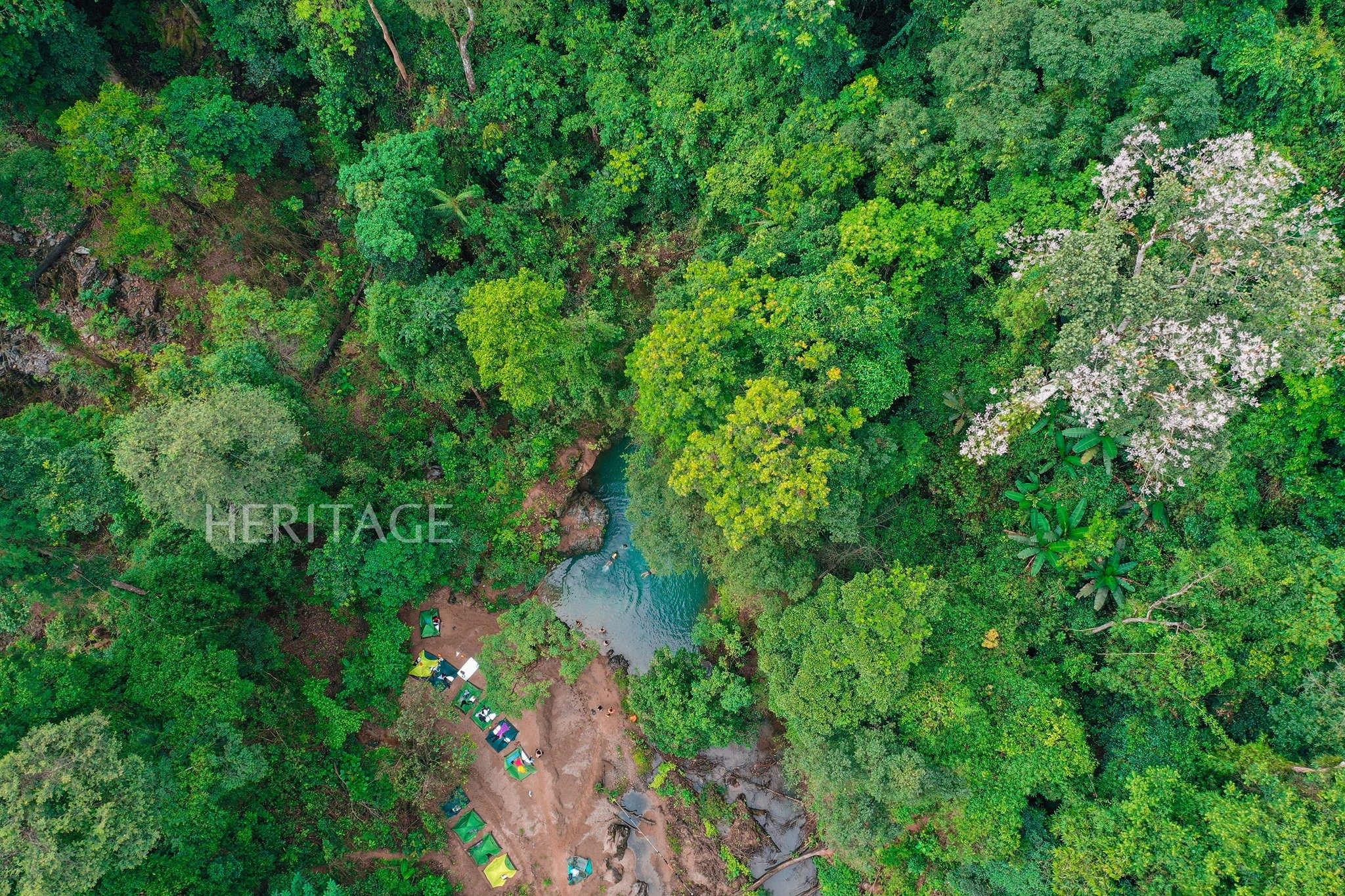

During the Green Vietnam Festival, TH brought a green space with a green economic model - a circular economy pioneered in all member units, attracting a large number of people to experience.

The green economic model - circular economy pioneered in all TH member units is the group's way of accompanying the Vietnamese Government's commitment to implementing the goals of combating climate change and sustainable development, towards Net Zero by 2050.

Therefore, at the Green Vietnam Festival, TH brought a practical story applied at the group.

Many solutions towards sustainable developmentDirectly experiencing the festival, Nguyen Thuy Linh (student of Hoa Sen University) said she was very impressed with TH's space when TH's emission reduction stories were told through squares with each side of the square being a story, each image of green development.

"I drink a lot of TH milk, but now I have the opportunity to learn about the green production process of the milk I drink, from raising cows, treating waste, using energy to treating wastewater," Linh said.

TH representative said that this enterprise has been serious and proactive in implementing sustainable development since its early days of establishment.

Since 2018, TH has started collecting sustainability data to not only understand the effectiveness of sustainability metrics, but also track how these metrics change over time. This demonstrates that TH Group has pioneered a circular economy, moving towards Net Zero.

As a founding member of PRO Vietnam, TH Group, through the alliance, collects used packaging, joining hands for a green - clean - beautiful environment.

In addition, TH annually organizes the campaign "Collecting cartons - spreading green living" at the TH true mart system. In 2023, the program collected 1.9 tons of packaging, an increase of 72% compared to the previous year.

In addition, TH has applied many solutions to reduce plastic, typically replacing plastic bags, plastic spoons, and disposable plastic straws with more environmentally friendly bioplastics, reducing the weight of each plastic bottle by 17%, reducing the thickness of bottle labels by 30%, reducing plastic on shrink wrap for some products, reducing the amount of glue used to attach straws to milk carton packaging...

According to TH Group, by synchronously applying the above solutions, TH reduces more than 600 tons of plastic per year, equivalent to saving about 16 billion VND.

Young people receive green gifts from TH representatives at Green Vietnam Festival - Photo: QUANG DINH

In 2023, TH will cooperate with the For Vietnamese Stature Fund and Green Future Plastic Company to complete a special school with part of the construction materials made from recycled plastic.

The school currently serves the learning and living needs of about 65 ethnic minority, poor and near-poor students in Trung Ha commune, Quan Son district, Thanh Hoa.

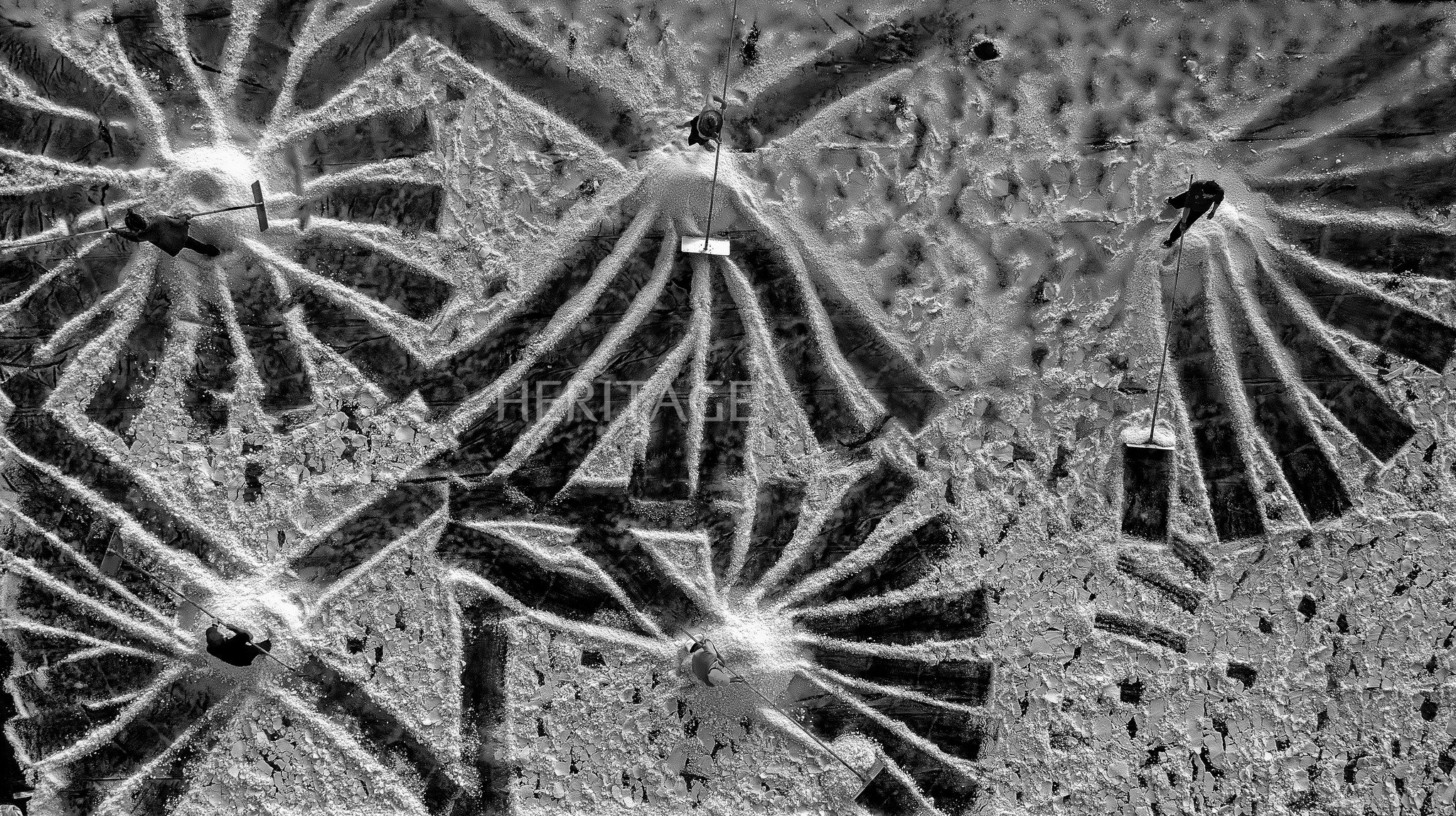

In addition, turning waste into resources is a typical mindset of the circular economy. At TH farm, organic waste is collected and processed into biological buffers to serve the farm and produce organic fertilizer.

In particular, TH is also a pioneer in reducing methane emissions thanks to advanced waste treatment technology, pioneering the use of renewable energy, using bagasse to produce electricity, treating wastewater to standards, using biomass fuel to replace fossil fuels...

Opportunities from circular economyMr. Mandal Arghya - Director of TH True MILK Joint Stock Company - said that this enterprise considers the circular economy not a pressure but an opportunity. Since the early days of establishment, the philosophy of sustainable development and commitment to environmental protection have always been the guiding principles for all our activities.

The company's slogan "Cherish Mother Nature" is not just an inspirational slogan but has been realized through each specific development step.

Gifts from TH were presented at the Green Vietnam Festival - Photo: BANG TAM

"We have established closed supply chains and we are still working towards that, in every step of the closed production process "from green pasture to clean glass of milk", ensuring that all production activities optimize resources.

For example, all wastewater and waste from the dairy farm is treated and reused, minimizing wastage,” said Mandal Arghya.

In addition, businesses are constantly investing in advanced technologies to make the production cycle "greener", thereby reducing emissions and increasing recycling capabilities.

According to Mr. Mandal Arghya, the transition to a circular economic model helps businesses not only protect the environment but also optimize production costs, create higher-value products and increase consumer confidence.

"Any business that recognizes and converts to this model early will have a sustainable competitive advantage in the future," affirmed Mr. Mandal Arghya.

Comment (0)