As a state-owned economic group with the task of contributing to ensuring national energy security, however, to produce 40-45 million tons of coal each year, Vietnam National Coal - Mineral Industries Group (TKV) has to use about 700kWh of electricity. In addition, mineral and alumina mining activities also consume a similar amount of electricity. To use electricity economically and effectively according to the Government's policy, TKV focuses on applying modern production technology, prioritizing the use of alternative energy sources to replace electricity and promoting responsibility and awareness among workers about using electricity economically.

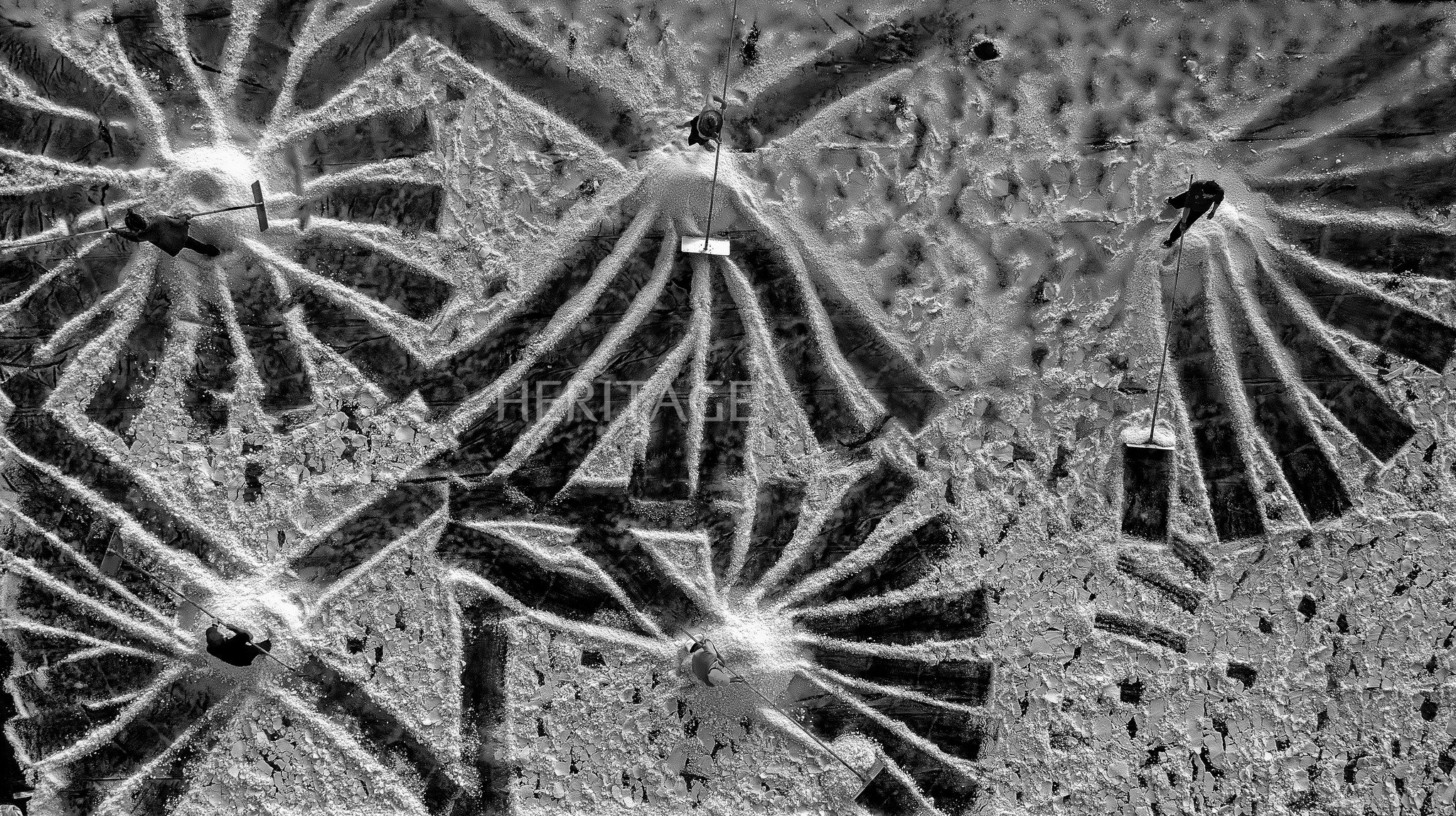

Pumping water from the mine is one of the activities that consumes the most electricity in the Ha Tu open-pit mine. Due to the extreme weather conditions, this year's rains have lasted longer and the rainfall has exceeded last year's. At this time, Ha Tu Coal Joint Stock Company has to mobilize 12 pumping systems, with a capacity of 400-1,300m3 /hour, to pump water from the mine.

According to Mr. Do Chi Dung, Deputy Head of the Mechanical and Electrical - Transportation Department of Ha Tu Coal Joint Stock Company - Vinacomin, the Company is currently mobilizing 3 pumping pits, from the bottom of the mine at level -109 to the intermediate levels -40 and -10, with a total of 12 pumping systems; consuming 400-1,000kWh of electricity. Therefore, in July and August, the electricity consumption for the pumping system was nearly 1 million kWh of electricity, double that of last year.

Along with the pumping systems operating at full capacity, 10 rotary drilling rigs of Ha Tu Coal Joint Stock Company are also consuming a huge amount of electricity, about 4.2 million kWh of electricity. In addition, 7 EKG electric excavators serving the excavation work at the Bac Bang Danh project site also consume over 3.7 million kWh of electricity per year.

Screening systems, auxiliary service activities such as repair, daily life... also consume a large amount of electricity every day. On average, each year, to exploit 2.5 million tons of coal, Ha Tu Coal consumes 20 - 22 million kWh of electricity, equivalent to a total cost of 31 - 36.5 billion VND/year. Therefore, Ha Tu Coal is identified as a key electricity user of TKV.

To both save electricity and ensure the productivity of machinery and equipment systems, Ha Tu Coal Joint Stock Company has developed a plan for efficient electricity use; especially focusing on activities that consume the most electricity.

Accordingly, the operation of the moong water pumping system has been carefully calculated by the unit, minimizing forced drainage pumping, leading to high power consumption. The reasonably planned pumping stations also help shorten the length of power cables and pipelines, to minimize voltage drops and power losses. Inverters and soft starters have also been installed for large capacity pump motor equipment. In addition, the transformer station serving the pumps is also regularly checked to avoid operating in no-load mode.

For drilling machines, Than Ha Tu has replaced the soft-start inverter for the drilling motor and replaced the oil circuit breaker with a digital relay vacuum circuit breaker at the 6kV electrical cabinet. Thanks to that, 1m of drilling of the machine now only uses 0.3 kWh of electricity, half of the previous time.

To save electricity used in EKG excavators, the unit has prepared well the production conditions such as working floor mirrors, blasting soil, machine foundation, etc. The equipment is arranged and balanced enough for the means of transport to work continuously, avoiding the situation of electric excavators running idle waiting for the vehicle.

For underground coal mining units, mine ventilation is the largest energy cost area, accounting for 20-40% of the mine's electricity consumption. In underground coal mines in Quang Ninh, the main fans have motor capacities ranging from hundreds to thousands of kW and operate around the clock. The air flow required for mine ventilation depends on the conditions and production plans. However, with current ventilation equipment in underground mines in Quang Ninh, fans must operate at the maximum flow rate according to design calculations. This leads to high electricity costs for fan motors.

However, this cost can be reduced by 40-50% by applying energy-saving measures to fan equipment as well as mine ventilation works. With the aim of saving electricity, Uong Bi Coal Company has chosen to adjust the operating mode of the fan station according to the actual requirements of wind consumers in particular and the entire mine in general. Applying frequency converters to bring the main fan characteristics to work in the appropriate mode by changing the rotation speed of the fan motor, reducing the overall ventilation power, contributing to reducing the cost of coal mining.

The efficient and economical use of electricity in coal industry units is also implemented in solutions such as using coal-fired boilers to replace electricity in bathing, washing, drying, and cooking; using LED lighting equipment and compact fluorescent lamps that have the same lighting level but consume less electricity than incandescent bulbs.

Thanks to the comprehensive and synchronous implementation of solutions for economical and efficient use of electricity, each year, coal production units have saved approximately 14 million kWh of electricity, significantly contributing to reducing coal production costs for TKV and fulfilling the responsibility of an enterprise in the field of national energy security.

Source

Comment (0)