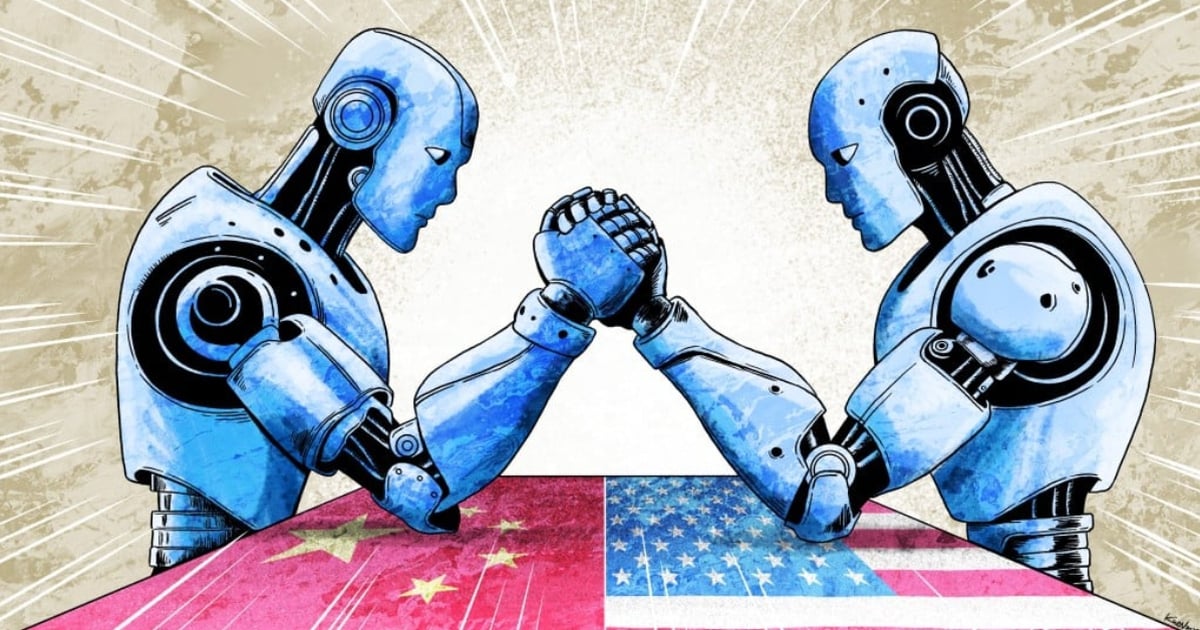

A report from ETNews (Korea) shows that Samsung's strategic plan is to create an artificial intelligence (AI)-based manufacturing ecosystem in the fields of product quality control and technological process management.

Samsung wants to build a chip factory without workers

Within six years, Samsung expects to have its first chip factories without workers, at least in regions where it has a long-standing presence. To prepare for this goal, Samsung is developing a “smart sensor” that can monitor the uniformity of plasma when processing silicon wafers. Such sensors are introduced at the monitoring stages of the silicon wafer etching process, the application of a chemical layer, and subsequent cleaning.

Until now, the Korean semiconductor industry has relied on foreign sensors in this area, but the new generation sensor was developed independently by Korean experts and will be manufactured in Korea. Deploying the sensor in existing factories will also not be too difficult because the small size of these sensors is remarkable, allowing them to integrate seamlessly into existing factories without requiring additional space, making it a valuable commodity in cleanroom environments.

It is known that among American companies, Tesla and Amazon are leading the way in automation as they try their best to reduce costs by replacing humans with robots. Therefore, Samsung's plan will help the company not to fall behind in its field of operation.

Source link

Comment (0)