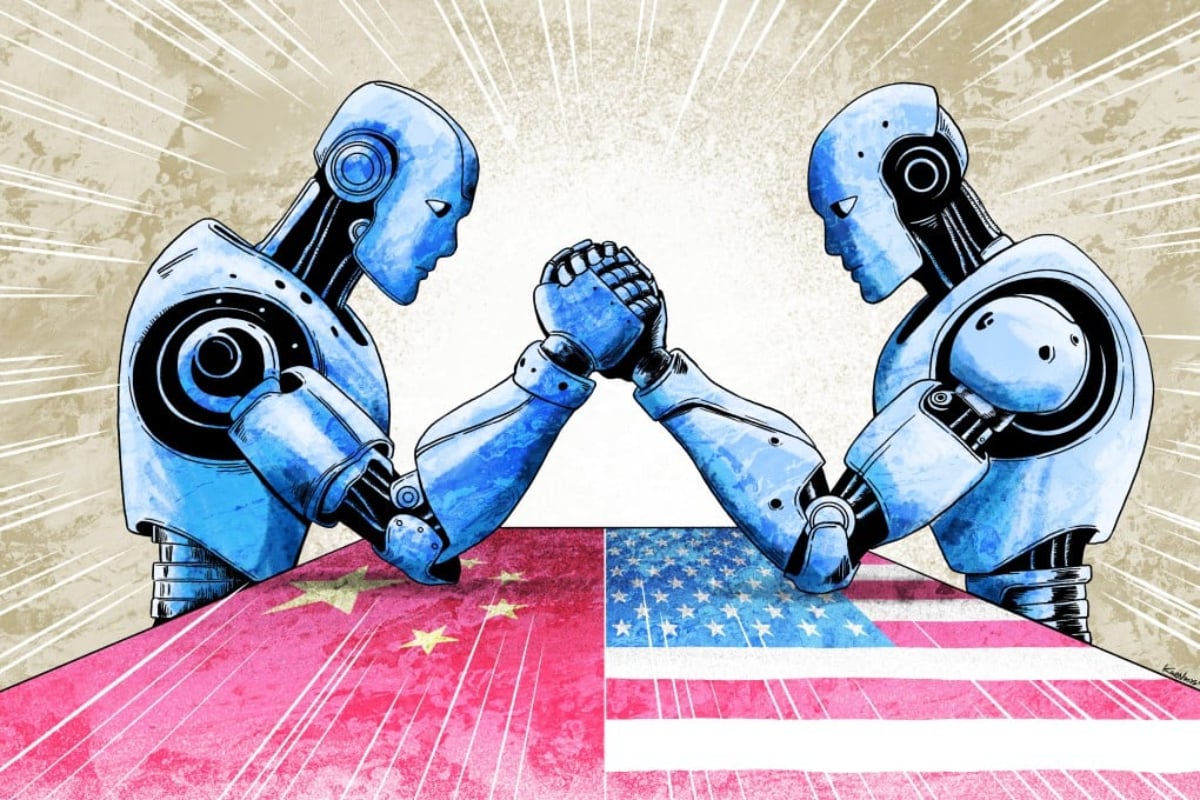

According to SCMP , the US is still the leading country in this field with outstanding products such as Boston Dynamics' Atlas humanoid robot and Stretch logistics robot. However, China is rapidly expanding its position in technology and robot production to challenge the US.

China's robot industry is threatening America

China’s push to produce robots domestically is going well, with domestic Chinese robot makers accounting for 30% of the market as of 2020 and expected to increase to 50% by March 2025, according to a report from analytics firm SemiAnalysis. Many Chinese manufacturers have shifted from the low-end robot market to higher segments, with the Unitree G1 being a prime example, which is highly regarded for its technological capabilities.

Platform for China's Robot Industry

Behind this development is strong momentum from the Chinese government, along with superior manufacturing capabilities and strategic investments. The Chinese government has identified the robotics industry as a key area in its national strategy and is promoting investment policies through the "Made in China 2025" plan. In particular, the government has invested heavily in humanoid robots, seeing them as a new driver for economic growth.

As the world 's factory, China possesses advanced mass production technology and a huge industrial base that gives it an edge in cost efficiency and production speed. For example, the cost of manufacturing a Universal Robots UR5e in the US is 2.2 times higher than manufacturing in China.

A humanoid robot from Unitree shows off its capabilities

Many Chinese robot manufacturers are actively researching the integration of key components, with ESTUN's in-house production rate reaching 95%, significantly improving the speed and flexibility of product development. Moreover, Chinese companies also dominate the global market for key components such as batteries.

Meanwhile, the domestic Chinese market is fiercely competitive, encouraging companies to develop and improve products quickly. A typical example is Shenzhen-based DJI, which has quickly optimized its production and supply processes, thereby creating a huge competitive advantage.

China’s robotics industry has also shown a high level of adaptability to changes in the external environment. During the Covid-19 pandemic, manufacturers quickly promoted automation to compensate for labor shortages.

The negligence of American companies

While the US still dominates the robotics industry, that dominance is slowly being eroded. SemiAnalysis points out that the US economy has shifted towards digital innovation and the service sector, leading to a decline in manufacturing capacity. Many US manufacturers have moved production facilities overseas to take advantage of lower costs, reducing domestic production capacity.

The truth about the robot that lured 12 other robots to quit their jobs and 'go home'

While China is developing its robotics industry through long-term initiatives, the US lacks a coherent strategy. Major companies such as FANUC, ABB, Yaskawa Electric and KUKA are less invested in research and development of next-generation robots than Chinese manufacturers. In contrast, China’s Siasun has acquired a vocational school in Germany to develop human resources and acquire technology.

SemiAnalysis emphasizes that “general-purpose robots” capable of performing any task in any environment are the “holy grail” of modern robotics. Countries that develop them successfully will reap great benefits. Currently, the US is well aware of its lag in the robotics industry and there are calls for cooperation between government , industry and research institutes. To prevent China from dominating the robotics industry and maintain competitiveness, the US needs to build a suitable national strategy, restructure domestic production, strengthen supply chains and invest in research and development.

Source: https://thanhnien.vn/trung-quoc-sap-vuot-my-ve-nganh-cong-nghiep-robot-185250317151915188.htm

![[Photo] National Assembly Chairman Tran Thanh Man holds talks with Speaker of the Malaysian House of Representatives](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/9/19/5cb954e3276c4c1587968acb4999262e)

Comment (0)