A group of scientists from Saigon University isolated two strains of microorganisms found in paper mill sludge to create bioplastic.

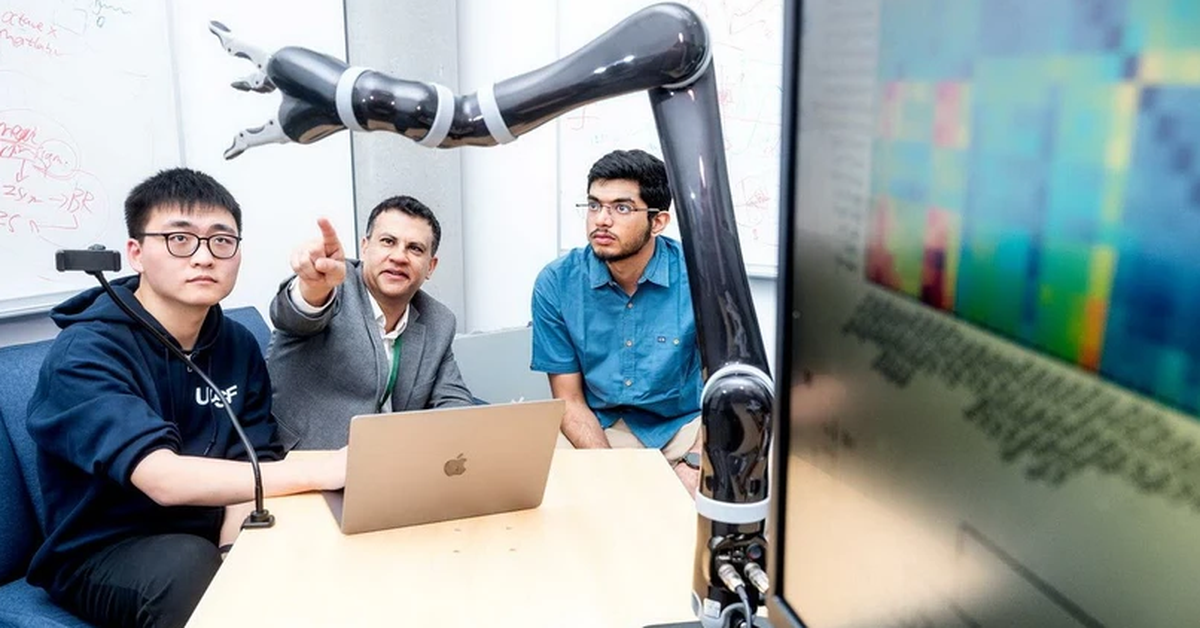

The research was conducted by Dr. Ho Ky Quang Minh, lecturer of the Faculty of Environment, and 10 colleagues since 2020 with the goal of creating bioplastics that can decompose in 30 days. The project also aims to recycle waste into useful raw materials according to the circular economy model.

According to Dr. Minh, wastewater (including sludge) from paper, seafood, sugar factories, etc. contains a lot of organic substances. Although this wastewater environment is quite harsh and contains many toxins, microorganisms can completely adapt to the mechanism of synthesizing and accumulating a type of polymer (bioplastic) in the body.

The research team used water and sludge samples from a paper factory in Tien Giang to analyze the microorganisms in the environment. Using methods of isolation, identification, and elimination of bacteria that can transmit diseases, the team found more than 100 strains of microorganisms capable of creating bioplastics.

Analyzing biological characteristics, the team evaluated two bacterial strains, Bacillus pumilus (NMG5) and Bacillus megaterium (BP5), as having the best plastic-making efficiency. "Among the bacterial strains we isolated, there are still many strains with higher efficiency," said Dr. Minh. Laboratory research results showed that these two bacterial strains have a rate of 40% of the accumulated dry mass as bioplastic.

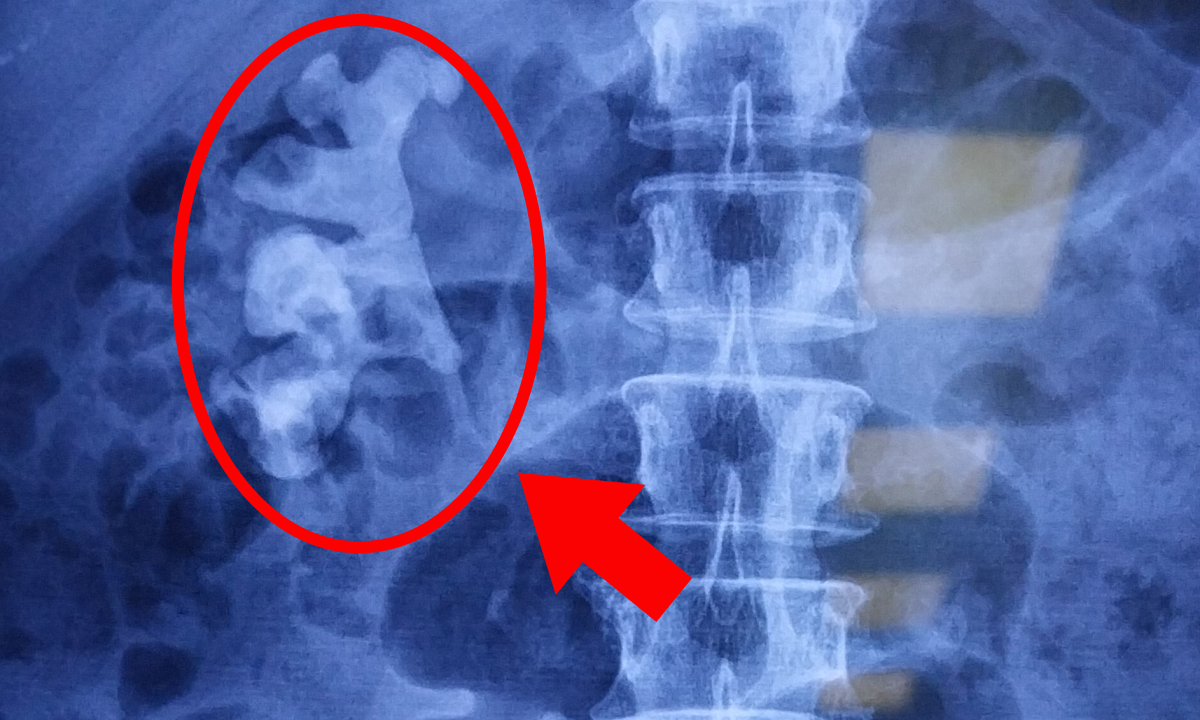

Testing the ability of biodegradable plastic (white) in the environment. Photo: NVCC

The paper mill in Tien Giang has a wastewater treatment capacity of about 30,000 m3 per day and night, of which 30% is sludge, or about 10,000 m3. The research team calculated that, in theory, about 40 tons of bioplastic could be obtained from microorganisms. However, Dr. Minh said that the case where the volume of bioplastic only reaches half of the theoretical calculation is also a very large proportion.

Through analysis, it is shown that microorganisms exist in the factory's wastewater sludge and use food from organic matter in the environment, so they have the ability to clean water. Accordingly, the group proposed that it is possible to develop into activated sludge blocks that both create bioplastics and treat water with better efficiency. To obtain bioplastics, it is necessary to use chemical or physical measures to break down the cell walls of microorganisms, which are usually made of polysaccharides. Then use a solvent to precipitate to obtain bioplastics. This plastic, when existing in the environment, will be a food source for surrounding microorganisms, so it will decompose very quickly.

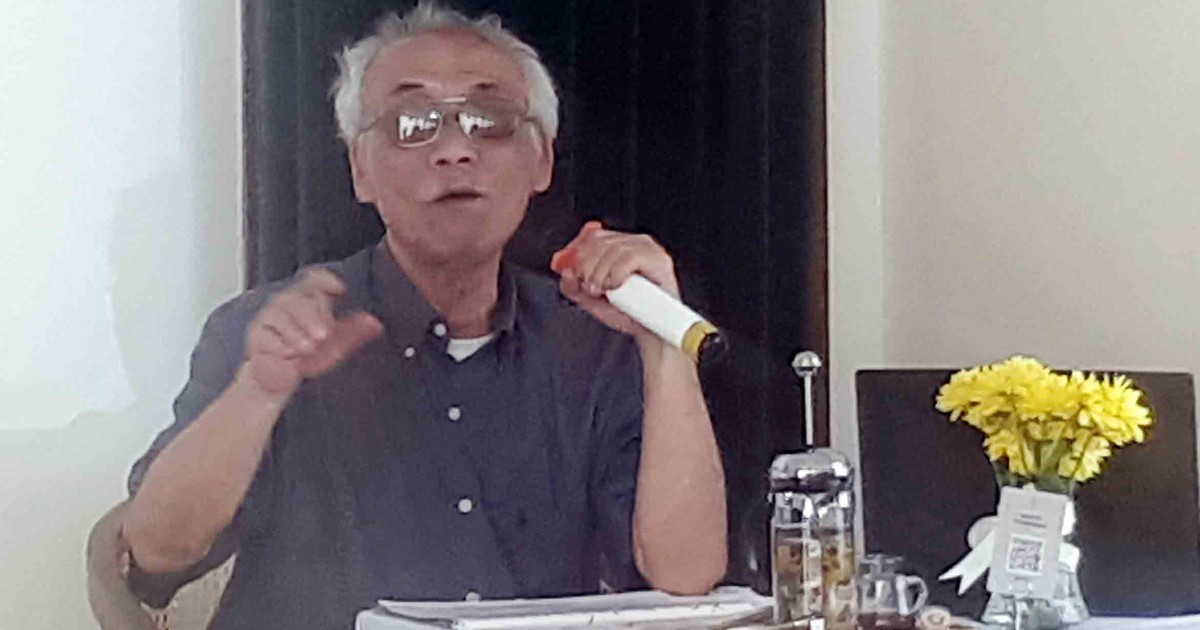

The research team coordinated with the paper mill to collect water and sludge samples for research. Photo: NVCC

Mr. Truong Minh Tri, Director of SG Workspace, a company specializing in investing in the field of environment and sustainable development, said that using microorganisms to create bioplastics and treat wastewater has been researched by many developed countries, and some places have applied it on an industrial scale. In Vietnam, there have been some studies on bioplastics serving environmental protection, agriculture...

According to Mr. Tri, the trend of recycling products to help protect the environment will become more popular in the next 5-10 years. However, recycled products from waste, in order to be popular and competitive in the market, must meet the requirements of quality and price compared to traditional products. To achieve this requirement, bioplastic products must be optimized to ensure quality and build large-scale production to reduce costs. At the same time, state policies need to set mandatory conditions to limit the use of traditional plastic bags, creating conditions for bioplastic products to penetrate the market more.

"With our group's project, we will continue to participate in laboratory-scale experimental stages to evaluate and coordinate with businesses to build pilot production processes and call for investment so that the product can soon be on the market," said Mr. Tri.

Ha An

Source link

Comment (0)