Since the Prime Minister's decision to establish the National Steering Committee on Green Growth in December 2021, the wave of response to green transformation - a new trend, even a "new rule of the game" of the market - has increasingly spread strongly, permeating the business thinking of Vietnamese enterprises.

999 VinFast electric cars are preparing to be shipped to the US.

VinFast's 6-year-old green ecosystem

August 15, 2023 is an unforgettable milestone for VinFast (Vingroup Corporation) when the company's VFS shares appear on the Nasdaq stock exchange (USA).

For the first time, a Vietnamese enterprise with the motto of aiming for a green future has officially stepped out into the world, confidently affirming a new business philosophy that is very suitable for the trend of the times, pioneering and leading.

Looking back on VinFast's 6-year development period since its establishment in June 2017, Chairwoman of the Board of Directors Le Thi Thu Thuy called VinFast's 6-year development journey "a mission to change the green revolution in the world, with the goal of producing an electric car that everyone can buy".

Entrance to VinFast factory.

In 2017, when VinFast first started building its factory, electric cars were already in its sights. However, to get acquainted and prove its production capacity, VinFast initially chose to produce gasoline cars. Once it had gained the trust of the market and was familiar with the industry supply chain, the company announced its shift to pure electric vehicles.

As a pioneer, pioneer, and professional, VinFast did not take much time to green its ecosystem. A series of electric cars under the VinFast brand were launched to Vietnamese and international consumers. VinFast cars have no exhaust emissions, limit air pollution, reduce noise pollution factors, do not use engine oil, and are manufactured with environmentally friendly materials. Chargers powered by renewable energy sources have less impact on the environment and natural resources than traditional gas stations.

More surprisingly, it has taken less than 6 years since its inception to present VinFast's electric vehicle ecosystem, covering all segments: from electric bicycles to electric motorbikes, electric cars and even electric buses.

Self-produced tungsten powder

Talking about the green transformation "revolution" of enterprises, Mr. Nguyen Thieu Nam - Deputy General Director of Masan Group - said that the goal of innovation needs to go straight to contributing to solving emerging issues, including climate change, green development, clean energy...

Therefore, Masan High-Tech Materials (a subsidiary of Masan) has just launched the globally registered Tungsten powder brand 'starck2charge®' used in the production of fast and safe charging Li-ion batteries.

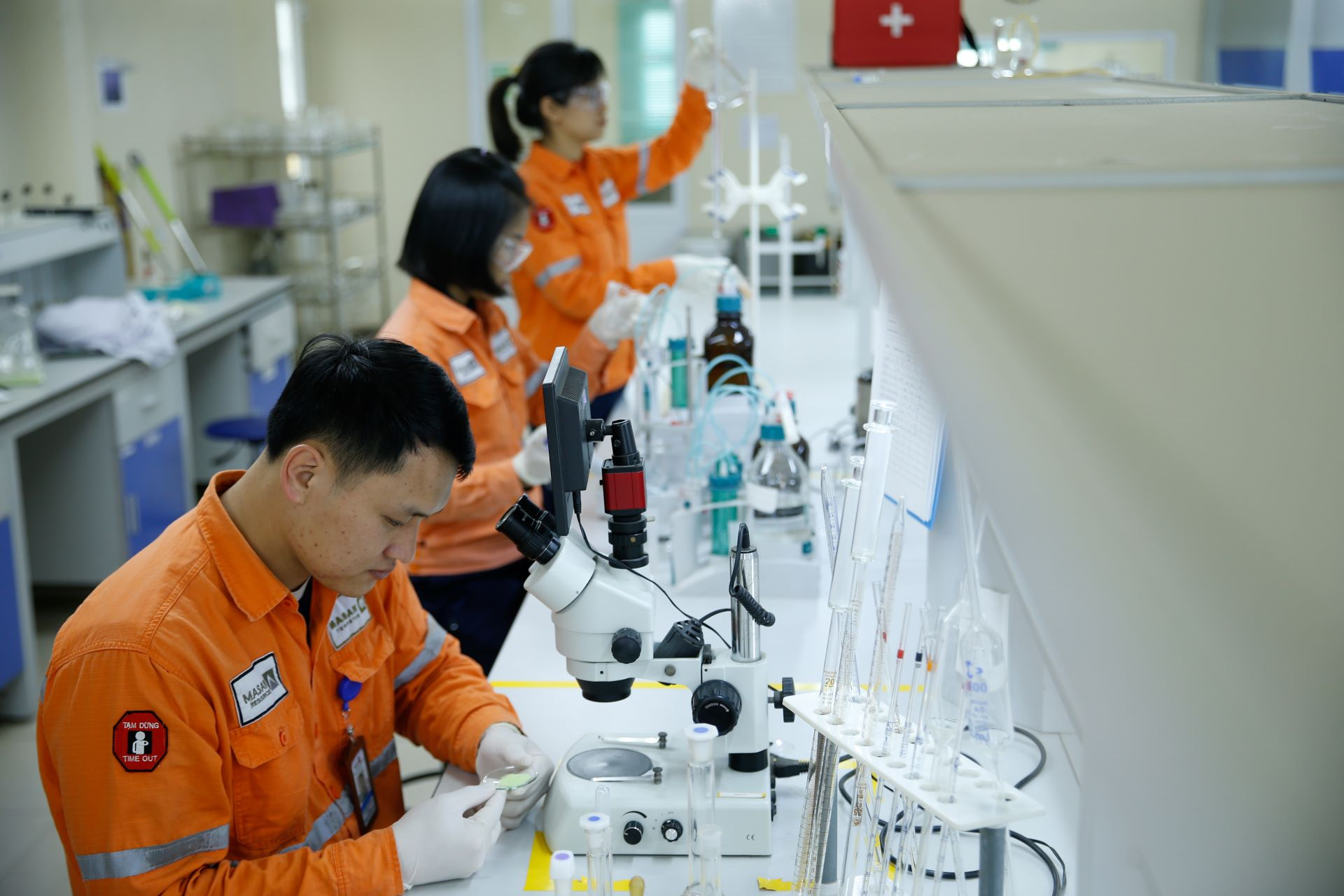

High-tech Tungsten Metal Powder and Tungsten Carbide Production at Masan High-Tech Materials.

This product is expected to help solve new energy problems and create a clean energy ecosystem, especially playing an important role in the electric car industry; or a mixed tungsten powder product serving industries using 3D printing technology with high stability and purity, especially suitable in the medical field.

Mr. Nam shared that Masan High-Tech Materials is the world's leading manufacturer of high-tech Tungsten metal powder and Tungsten Carbide, with production complexes in Vietnam, Germany, Canada and China, and owns two research and development centers in Germany and Vietnam.

Masan High-Tech Materials is planning to build Asia's first and largest tungsten recycling plant in Thai Nguyen, aiming to turn Vietnam into a leading center for developing tungsten and precious metals recycling technology in the region.

In addition, Masan High-Tech Materials also started planting trees on the waste rock land after mineral exploitation since 2016. To date, the company has covered about 58 hectares of the project area with greenery - a part of carbon absorption to be able to pursue the goal of carbon neutrality in the future.

“This requires businesses to restructure their business models in the long term, towards digital transformation, production technology transformation, and applying global green and sustainable standards to products and services, ” Mr. Nguyen Thieu Nam affirmed.

Masan Group brings clean products to consumers through its retail system.

Reduce greenhouse gas emissions by all means

After many drastic solutions and actions, in 2022, TH's farm system reduced emissions by more than 20% per product unit. Carbon emissions at the group's factories decreased to 0.1 kg CO2 per product, down more than 30% compared to 2021. This is an outstanding emission reduction compared to the emission reduction results of dairy factories in Vietnam and Southeast Asia.

TH factory uses solar batteries.

In addition, TH also reduced the consumption of gasoline and fossil fuels at factories by switching to using biomass fuel (burning wood chips as by-products from the wood processing industry). By making this change, the Group's entire factory system reduced total greenhouse gas emissions by more than 85% compared to 2021.

All lighting in TH's farms and factories have been converted to LED lights, saving 5,000,000 kWh of electricity, equivalent to reducing 4,000 tons of CO2.

To take care of the sunflower, corn, sorghum and grass fields, TH farm invested in a "giant arm" automatic irrigation system 500 - 700m long.

In the general trend when businesses deploy renewable energy to protect the environment and meet production needs, TH has deployed a rooftop solar power project since June 2020. Currently, the whole Group has 6 solar farms with an amount of electricity equivalent to 1/8 of the demand. The solar power system has helped TH save 29,000 kWh/month, contributing to a sharp reduction in emissions into the environment.

According to TH representative, after reduction, "absorption" is an important step towards the Net Zero goal. This group has been carrying out greening and tree planting activities to absorb and compensate for the amount of CO2 emitted during the production process. In 2021 and 2022 alone, the group has planted nearly 50,000 new trees of various types in the factory area.

Source

Comment (0)