From 2023, Masan High-Tech Materials Joint Stock Company (MSR), a subsidiary of Masan Group, will focus on the Tungsten Recycling Plant Construction Project. In addition to innovative high-tech materials activities, the project is expected to contribute to the completion of the circular economic model, with a closed-loop chain including the collection, recycling of scrap materials, and return of production materials.

Putting scrap into new production

The ambition of the project to build a tungsten recycling plant was revealed by Masan High-Tech Materials leaders late last year, then officially announced at the shareholders' meeting last April.

The company representative said that it will build the first and largest tungsten recycling plant in Asia in Thai Nguyen, and aims to make Vietnam a leading center for developing tungsten and precious metals recycling technology in the region.

Recycling scrap to put tungsten into new production cycles is an important direction in the context of the world supply (outside China) only meeting 20% of demand, according to the company's leaders. Meanwhile, the demand for high-tech materials will increase due to the trend of moving factories out of China, especially in the electronics and telecommunications sectors.

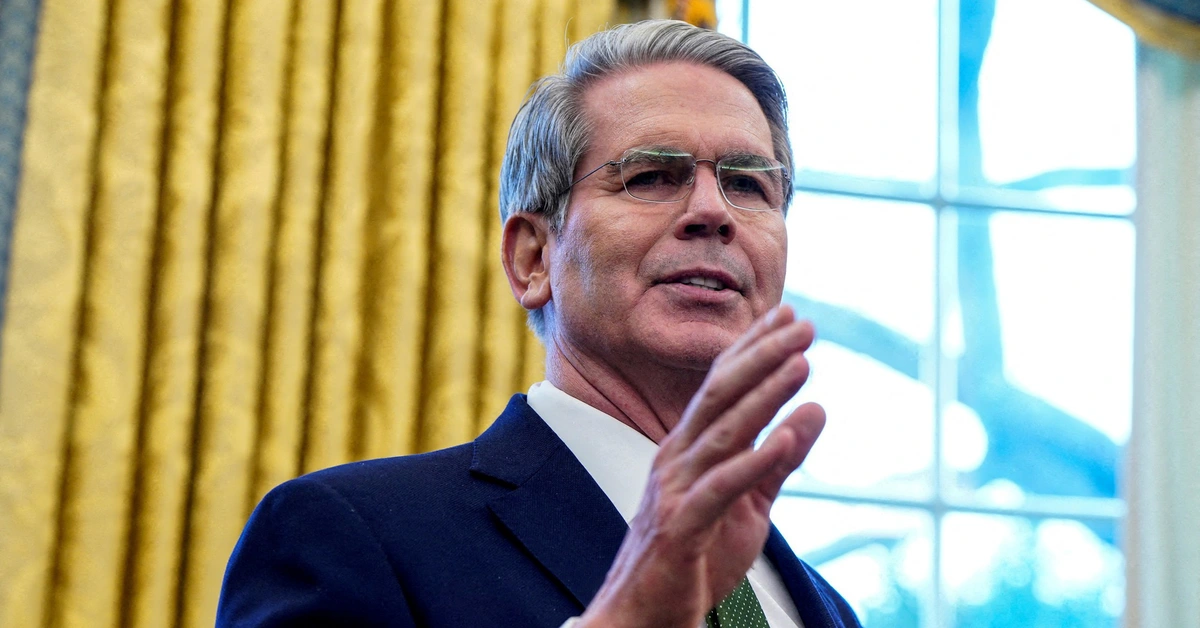

An engineer at a scrap recycling plant. Photo: Masan High-Tech Materials

"Currently, increasing demand requires ensuring output. Limited reserves in mines require finding Tungsten from recycled and scrap sources to turn into high-tech Tungsten products for customers. In fact, customers are demanding and requiring the company to provide Tungsten products with a certain proportion of recycled Tungsten," the company's leader shared at the congress.

The recycling plant is located at the Nui Phao polymetallic tungsten mine in Thai Nguyen province. The input material comes from the recovery and recycling of waste from tungsten production activities. On the other hand, the company will also purchase scrap, currently targeting some purchasing areas in Asia - Pacific, to provide input for the tungsten recycling plant.

According to the company's leadership, even sourcing and purchasing high-quality tungsten scrap is increasingly competitive, especially in the current geopolitical environment. However, there are still many raw materials containing tungsten that have not been recycled.

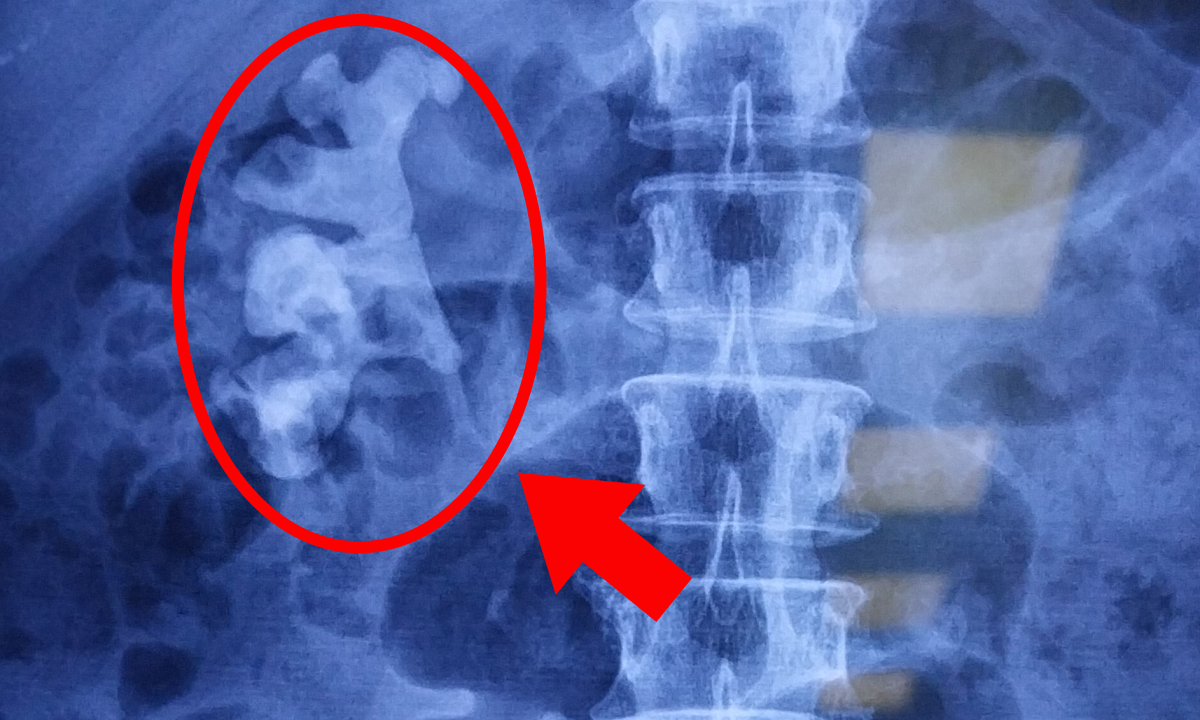

According to the International Tungsten Industry Association (ITIA), the recycling rate of cemented carbide scrap can be as high as 80%, while used catalysts containing tungsten are often piled up in hazardous waste landfills.

The Tungsten recycling plant will help Masan High-Tech Materials reduce its dependence on primary raw materials from mineral mining activities, while creating a closed value chain including collection, recycling of scrap materials, and return of production materials, thereby improving mining efficiency and business performance.

Masan High-Tech Materials' modern processing plant in Thai Nguyen. Photo: Masan High-Tech Materials

The company also has high hopes for a project to recycle waste battery materials, also known as black matter (a mixture of active material particles from Li-ion batteries and key components containing recyclable metals such as cobalt, nickel, manganese and lithium). The project has started with preliminary engineering design and pilot testing of a new recycling process.

"Tungsten will be recovered from used and recycled battery products and 3D printing materials, becoming an input material for new products," the company representative shared.

Towards sustainable development

Recycling is a key project, so Masan High-Tech Materials is focusing on research and implementation. 2023 is considered the right time for the company to promote recycling activities after a series of important preparations over the past two years.

Recycling of tungsten-containing scrap requires new modern technology that can recover and synthesize to create raw materials suitable for industries. The technology of the tungsten recycling plant in Thai Nguyen is initially applied from HC Starck (Germany), whose tungsten business platform was acquired by the company in 2020. This is one of the few companies that owns exclusive patents and has a comprehensive and environmentally friendly tungsten recycling platform.

The technology will then be continuously improved and innovated to build environmentally friendly processes based on world-leading research and development (R&D) and recycling experience in Germany, as well as research activities in Vietnam.

In recent times, the company has stepped up its R&D activities, building laboratory-scale and pilot-scale testing areas at its R&D facilities to complement its existing facilities in Goslar (Germany). The new facility will enhance the company’s capacity for in-depth research in this field and recycling of a wider range of scrap materials.

The "Recovery - Recycling - Reuse" model of materials is considered by businesses to be the most effective method to optimize resources, contributing to the sustainable growth of the country and the world.

"The recycling platform is considered an important piece, not only helping businesses create a revolution in renewable energy and new materials, but also contributing to promoting environmental protection, aiming for green growth and sustainable development. The success of the recycling project will also affirm the capacity to develop high-tech materials, helping to increase Vietnam's competitive position in the international tungsten market," said a representative of Masan High-Tech Materials.

Recycling tungsten scrap at Masan High-Tech Materials. Photo: Masan High-Tech Materials

In the first quarter of 2023, HC Starck will introduce a globally patented tungsten powder product, which is expected to help solve new energy problems and create a clean energy ecosystem, especially playing an important role in the global automotive industry. Another product serving industries using 3D printing technology, with high purity and stability, is of great significance in the medical field.

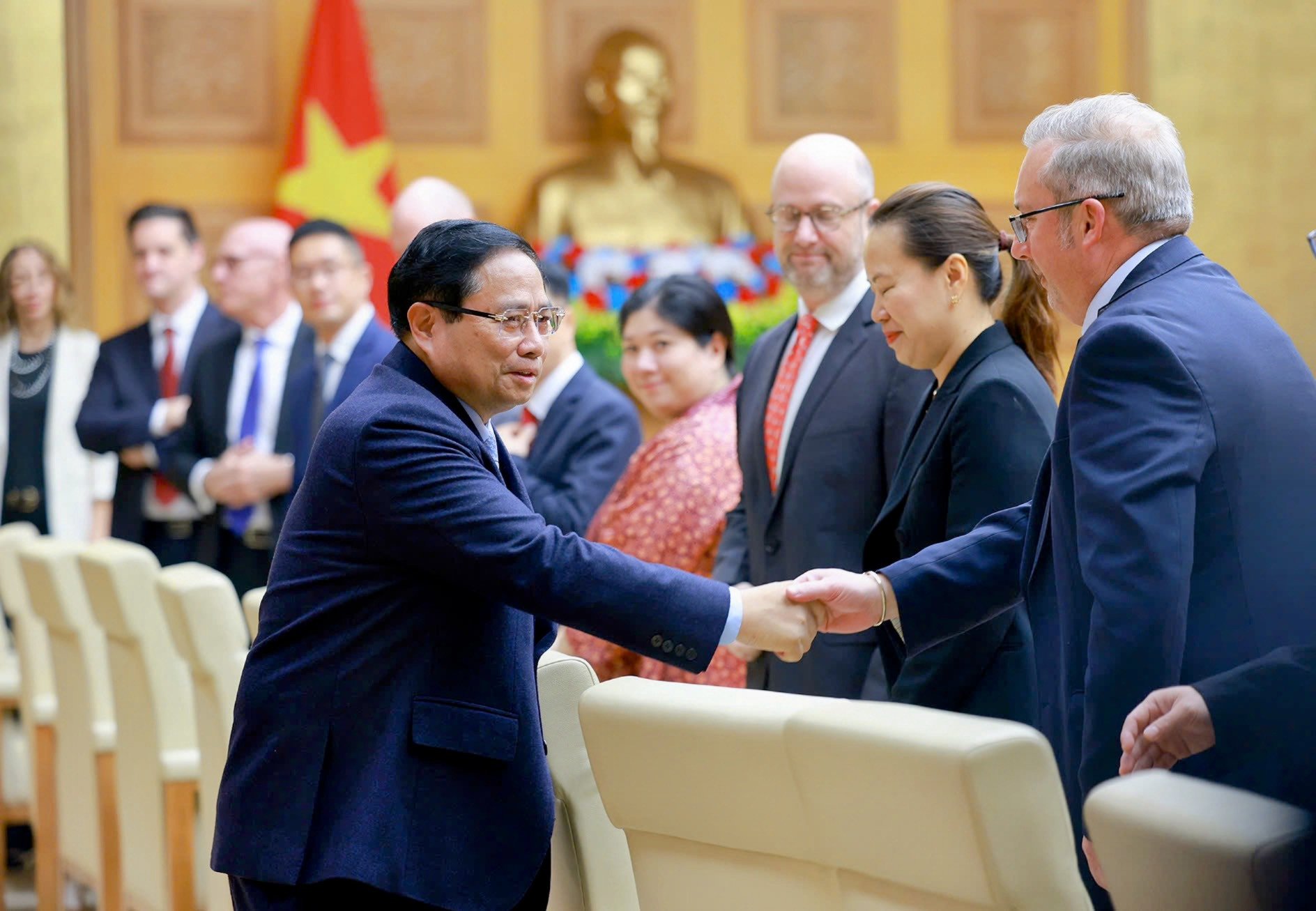

"In the next 5 years, the company aims to not only be the world's leading supplier of high-tech materials but also directly participate in and lead the global consumer technology products market in the near future. We are confident in mastering the world-class, comprehensive and environmentally friendly tungsten recycling platform while creating new sources of raw materials. This is the strategic pillar that brings success to the company," said Mr. Danny Le, Chairman of the Board of Directors of Masan High-Tech Materials, about the future strategic vision.

Wind and Cloud

Source link

Comment (0)