SGGPO

3D factory with full functional areas and professional processes has been officially put into operation by 3D Smart Solutions Company.

|

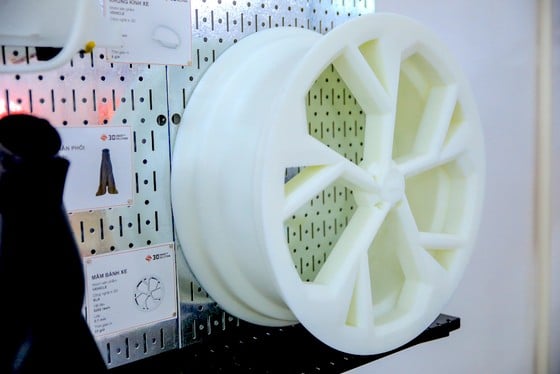

| A corner of 3D Smart Solutions factory |

After nearly 1 year of construction, installation and acceptance according to international standards, the 3D printing factory of 3D Smart Solutions Company (also known as 3DS) has been put into operation at Long Truong ward, Thu Duc city.

3D Smart Solutions representative said that this 3D factory can serve many needs in many industry groups such as: Supporting industry - B2B outsource (small batch production, prototyping, advertising, new product design...); Healthcare (design and manufacture of treatment support tools for orthopedic trauma treatment, 3D printing of surgical guide trays for implant placement in dentistry); Education (production of teaching models - STEM, training of human resources in the field of 3D technology); Architecture (processing of diorama, miniature architectural models, design and manufacture of complex deformable concrete molds); Fashion (Full body scanning in the modern garment industry); Cinema (design and manufacture of tools, film props)...

|

3DS's 3D workshop has 9 specialized functional areas for a large-scale professional 3D printing workshop. There is a 3D solution display area, a training room, a 3D printing workshop, including 3 technologies: FDM, SLA, SLS, a 3D scanning workshop, an industrial design room...

Regarding machinery infrastructure, 3D Smart Solutions' new factory has a total of 4 units of industrial 3D printers, 10 units of professional 3D printers, 2 units of industrial 3D scanners, 4 units of handheld 3D scanners and CNC cutting and machining systems.

|

This modern machinery and equipment chain is imported by the company in full solution from major brands in the world such as Formlabs (USA), Eplus 3D (China), Cubicon (Korea), Shining 3D (China), HAAS (USA). In addition to the 3D machinery and equipment system, 3DS company invests in using copyrighted software such as CAD software - Solid Edge, design software for 3D printing - VoxelDance.

With the system operated and controlled semi-automatically by IT built by the company's IT team, the output capacity of additive manufacturing reaches 250kg/month for rough production, 100kg for fine production. In addition, the capacity of 3D inspection reaches 3000 finished products per month and meets 2 monthly product design contracts.

|

Currently, 3D Smart Solutions' 3D printers use a variety of materials for their production process, from plastic filaments (ABS, PLA, PEEK, PA12-CF), Resin (Tough 1500, Tough 2000, Rigid 4000, Castable wax...).

In addition, 3D Smart Solutions is also gradually applying artificial intelligence in some processes, while adhering to very strict production standards to achieve high efficiency and capacity for this line.

Specifically, in addition to temperature and humidity for the machinery system, preservation stage... the standardized operating process from the research and analysis steps, 3D design, testing or mass production (small scale) to packaging and delivery all ensure the strict requirements of this industry.

|

Mr. Truong Tan Tong, founder and CEO of 3D Smart Solutions Company said: “With the current facilities and technical team, we are very happy. 3D Smart Solutions confidently commits to professionalism in consulting, providing and transferring technology for 3D solution packages in Vietnam and conquering the goal of becoming the leading 3D printing factory in Southeast Asia and the dream of IPO in the next 5-7 years”.

Source

Comment (0)