MIT experts develop 3D printing technology that is 10 times faster than similar metal 3D printing processes, although still limited in aesthetics.

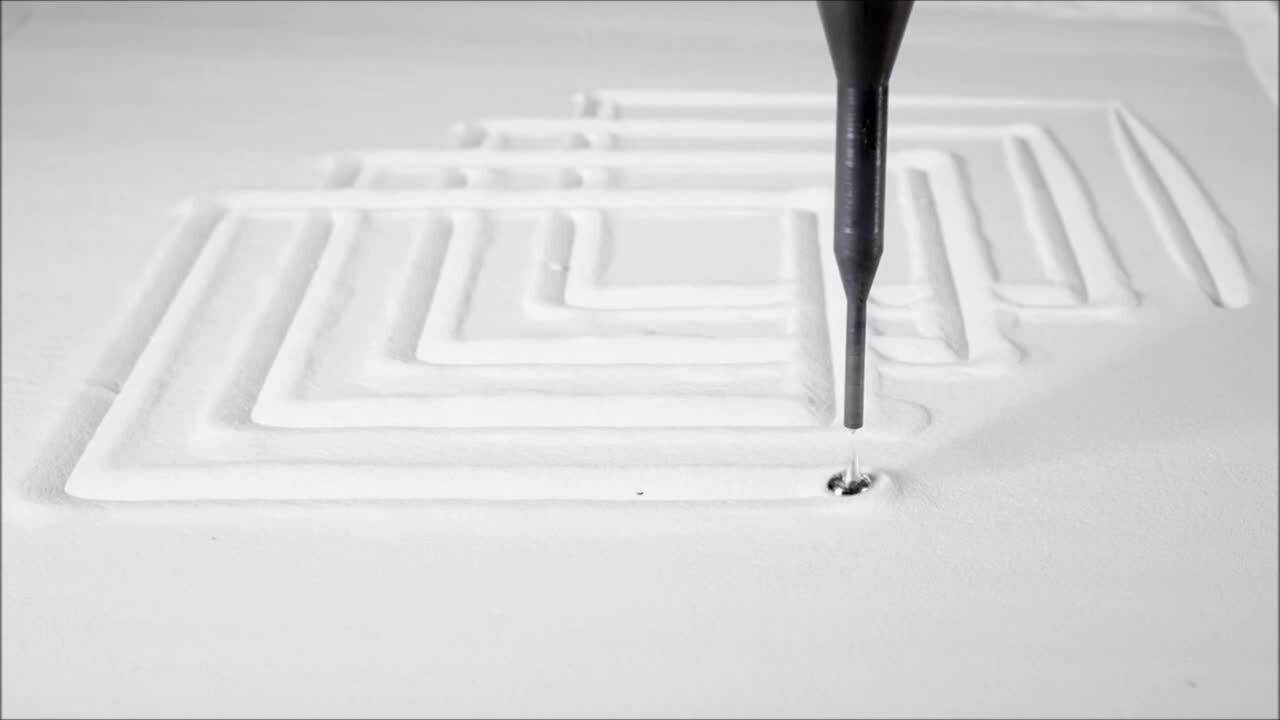

3D printing of furniture parts using liquid metal. Video: MIT

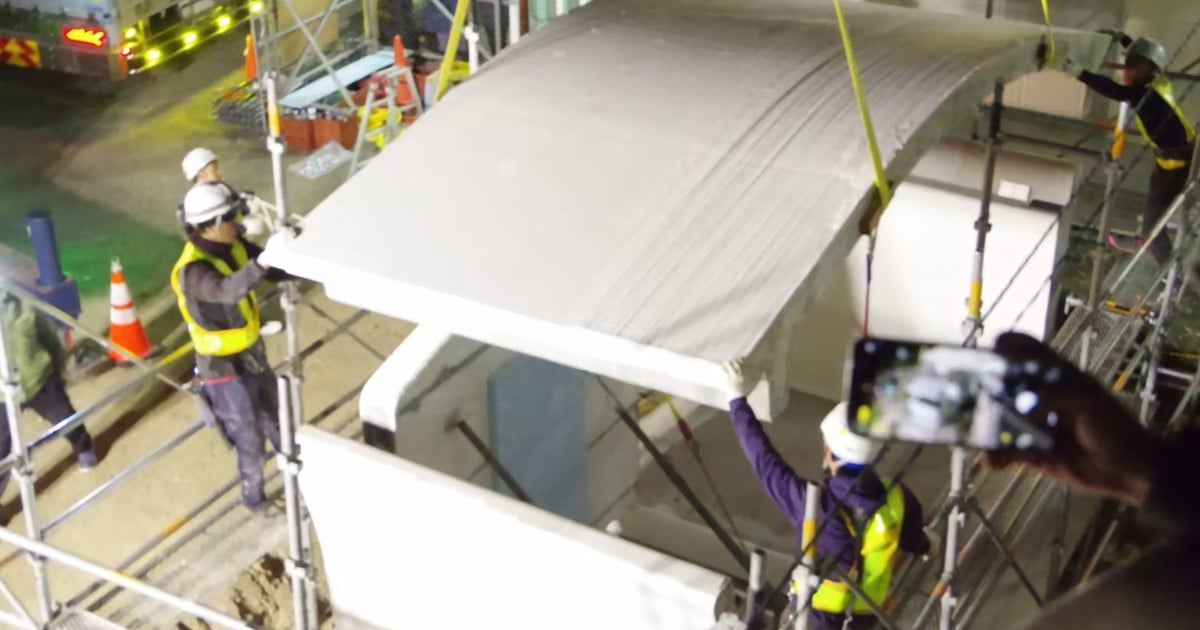

In a new study, the Massachusetts Institute of Technology (MIT) 3D printed furniture parts such as frames and legs of tables and chairs with liquid metal, obtaining sturdy parts in just a few minutes, Design Boom reported on January 26. The printing process begins by spraying liquid metal, specifically aluminum, in a pre-designed shape. The liquid metal quickly hardens and takes shape.

Liquid Metal Printing (LMP) technology allows 3D printing to be 10 times faster than similar metal 3D printing processes, researchers say. Smelting metal can also be more efficient than some other methods, as metals are easier to find and there is an abundance of scrap that can be recycled.

LMP is promising, but it has its limitations, says Skylar Tibbits, an associate professor in the MIT Department of Architecture and a member of the research team. For example, the technology allows for fast printing of large objects, but the resolution and aesthetics are not high. The printed objects have rough and uneven surfaces.

“But most of the things that are built in the human world, like tables and buildings, don’t need very high resolution. Meanwhile, speed, scale, repetition, and energy consumption are all important parameters,” said Skylar Tibbits.

The MIT team also built a machine that can melt aluminum, hold the molten metal, and then spray it out of a ceramic nozzle in a pre-designed shape. “Molten aluminum destroys almost everything in its path. We started with a stainless steel nozzle, then switched to titanium, and finally ceramic. But even ceramic nozzles can get clogged because the heat isn’t always uniform across the nozzle,” says Zain Karsan, a PhD student at ETH Zurich.

LMP enables rapid 3D printing of furniture parts and other objects using liquid metal. Because the molten aluminum cools in just a few minutes, users can use the newly created products immediately. The team also found that the larger the amount of aluminum they melted, the faster the printer could operate. In the future, they want to find ways to keep the temperature stable in the nozzle and prevent the liquid metal from sticking, while also creating better material flow and finding design solutions that increase the uniformity and smoothness of the products.

Thu Thao (According to Design Boom )

Source link

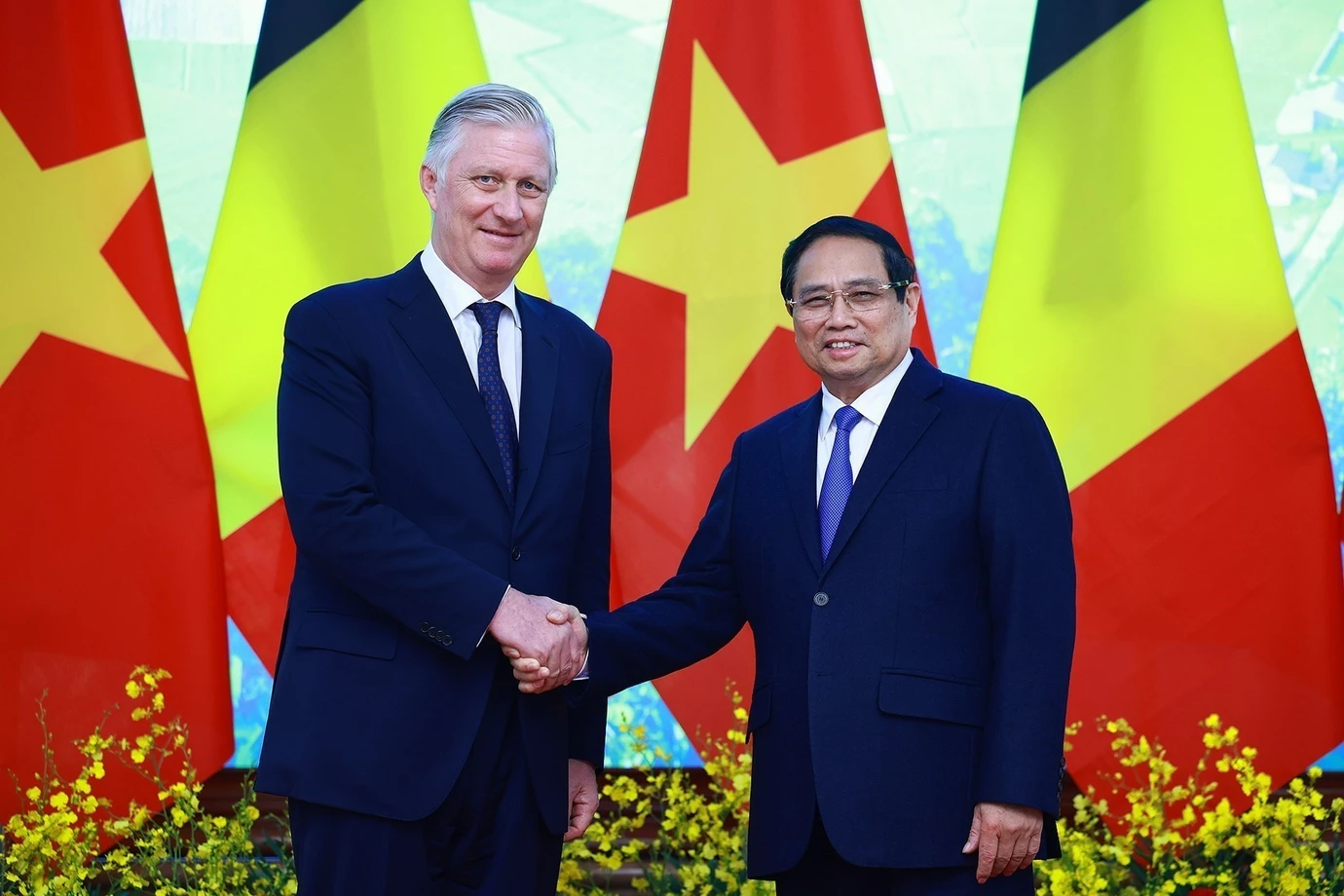

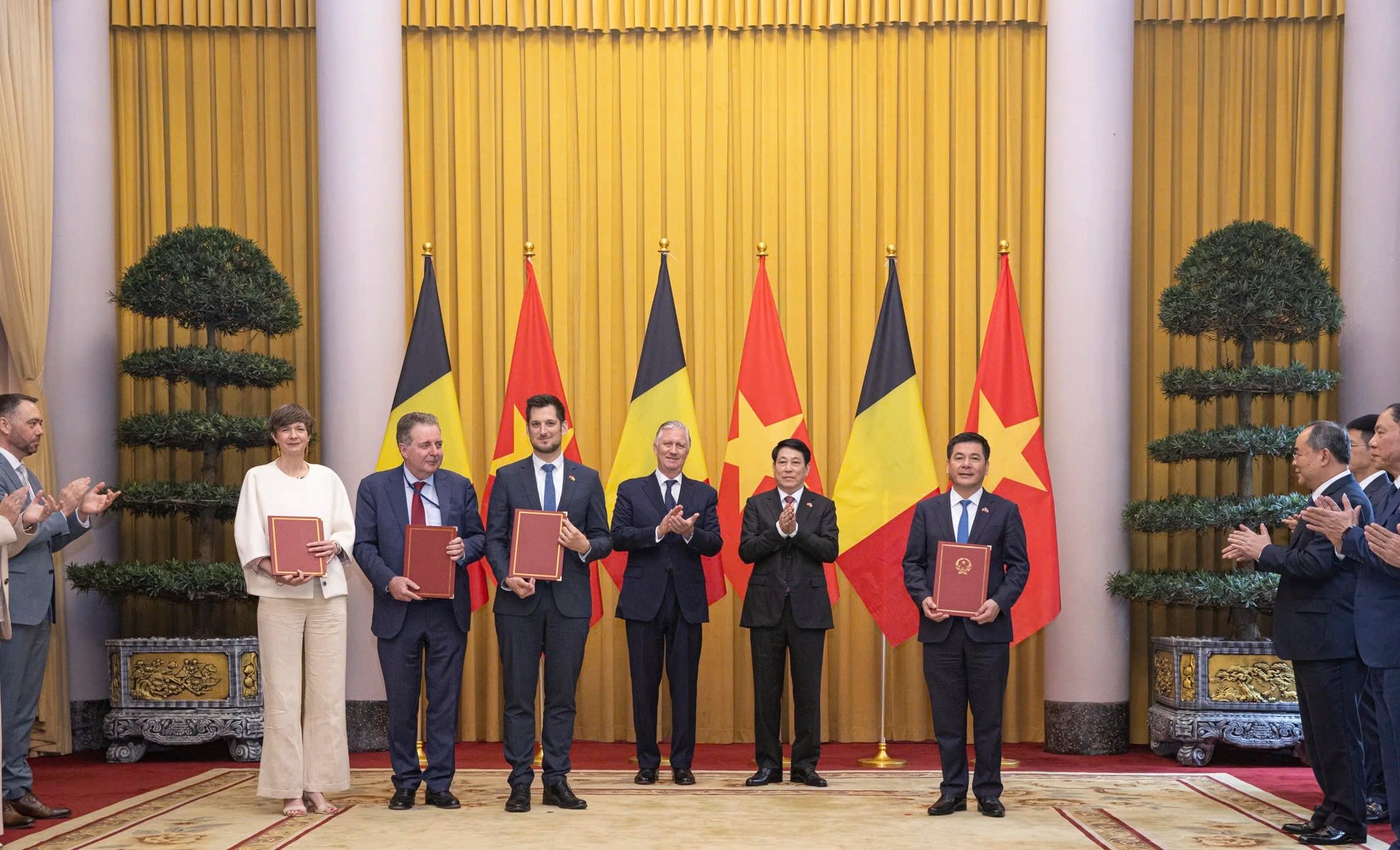

![[Photo] Prime Minister Pham Minh Chinh meets with King Philippe of Belgium](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/be2f9ad3b17843b9b8f8dee6f2d227e7)

![[Photo] Close-up of Vietnam's sniffer dog team searching for earthquake victims in Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/d4949a0510ba40af93a15359b5450df2)

![[Photo] General Secretary To Lam receives King Philippe of Belgium](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/e5963137a0c9428dabb93bdb34b86d7c)

![[Photo] President Luong Cuong and King Philippe of Belgium visit Thang Long Imperial Citadel](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/cb080a6652f84a1291edc3d2ee50f631)

![[Photo] Myanmar's capital in disarray after the great earthquake](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/7719e43b61ba40f3ac17f5c3c1f03720)

Comment (0)