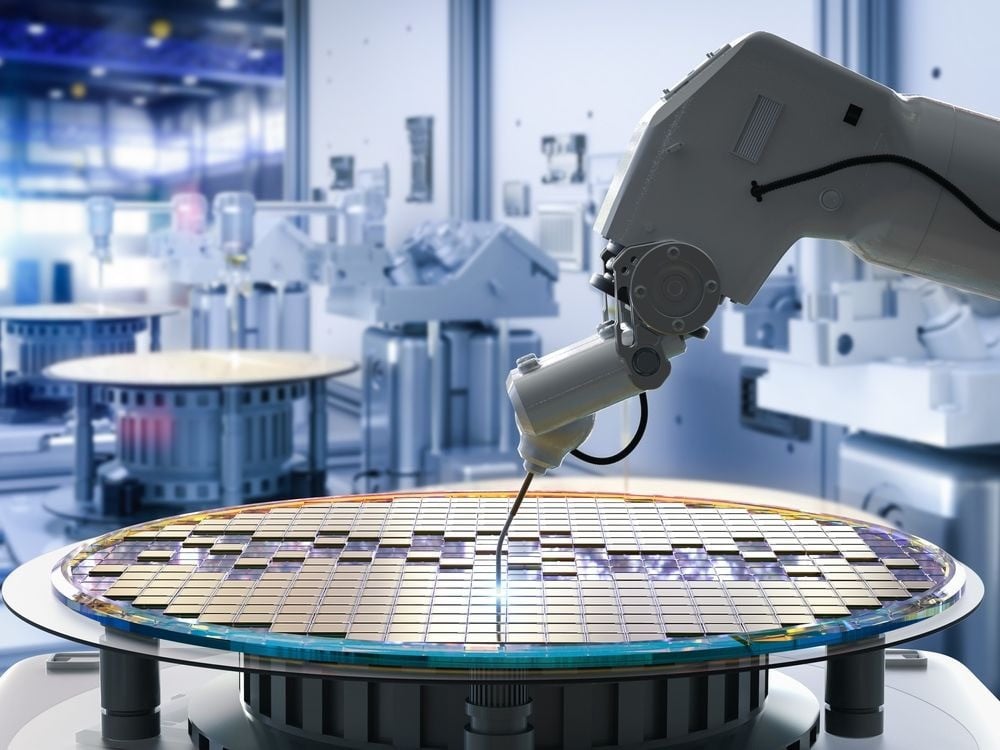

TSMC, Intel, and Samsung are expected to produce sub-2nm Angstrom lithography chips in the coming years. Senior semiconductor industry executives say the transition will be impossible without significant innovation in semiconductor materials and chemistries.

James O'Neill, technical director of materials supplier Entegris (USA), said that lithography equipment is no longer the decisive factor in the ability to create breakthrough semiconductor engineering processes. That role has shifted to new materials and advanced cleaning solutions, used in the processing of silicon wafers.

According to James O'Neill, it is innovations in the field of materials that will bring breakthroughs in increasing the productivity of semiconductor components.

Kai Beckmann, CEO of the German chemical group Merck, supports this view, explaining that for more than 20 years, progress in the semiconductor field has been determined by specialized lithography equipment, but the coming decade will be the “material era”.

Sophisticated devices will still be important, but new materials will make the difference. This is true not only for mobile chips, but also for memory chips. For example, 3D NAND solid-state memory currently uses more than 230 storage layers, and in the future this number could increase to 500 layers.

For chemical processing in semiconductor chip manufacturing, James O'Neill believes that next-generation chemicals must provide the ability to process silicon elements with high precision, at the atomic level.

The purity of the solutions used is of particular importance, as they directly affect the defect rate during chip manufacturing.

Copper has long been used as a conductor, but as chip sizes have shrunk, the problem of finding new materials, similar to the discovery and application of molybdenum, is considered a challenge for the entire development of the semiconductor industry.

Moving to new lithography standards will likely require a completely new set of materials, which requires significant investment, making it nearly impossible for new players to gain a foothold in the semiconductor market.

Entegris CEO Bertrand Loy believes the semiconductor industry's growth outlook will continue to be shaped by the largest companies in the market today.

Large companies will always be willing to invest in new technologies, as it will give them a competitive advantage and the opportunity to get ahead of their competitors.

(according to 3dnews)

Samsung deals a heavy blow to America's ambitions for semiconductor self-sufficiency

US reviews semiconductor supply chain, concerns about national security

Samsung to get $140 million to build semiconductor facility in Japan

Japan joins global semiconductor manufacturing race

Source

![[Photo] Paris "enchanted" by the blooming flower season](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/21/e967dc548ff74f9ca8e89d72c3608825)

![[Photo] President Luong Cuong receives former Vietnam-Japan Special Ambassador Sugi Ryotaro](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/20/db2d8cac29b64f5d8d2d0931c1e65ee9)

Comment (0)