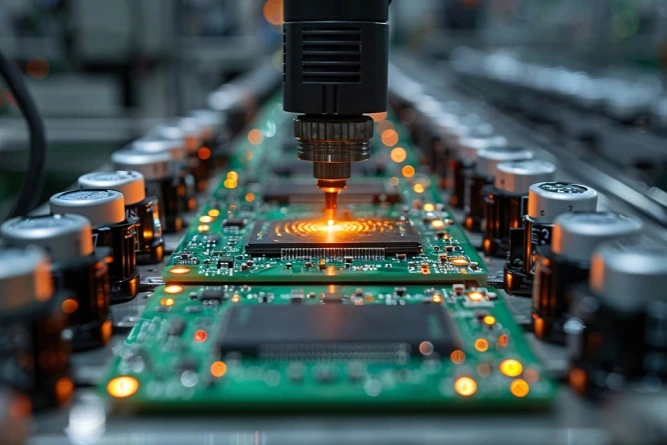

At the heart of this mission are lithography machines, which are critical to the production of advanced microprocessors. Export restrictions by the US and its allies have reduced Huawei’s access to these machines, as the chip foundry market is dominated by three giants: ASML (Netherlands), Nikon and Canon (Japan).

The new R&D center, located in western Shanghai, will include a key microprocessor development facility and a new headquarters for HiSilicon Technologies, Huawei's chip design unit. It will also house a research center for wireless technology and smartphones.

The city government said the total investment of this project is about 12 billion yuan ($1.66 billion), making it one of Shanghai's top projects in 2024.

To put that into perspective, the project is the size of 224 soccer fields combined. Huawei also designed a tram that will move between buildings on the campus. When completed, the center will be able to accommodate more than 35,000 high-tech workers.

Huawei's R&D expenditure in 2023 reached a record 164.7 billion yuan, accounting for 23.4% of the group's total revenue.

Before being blacklisted by Washington, the company primarily designed chips and outsourced manufacturing to foreign partners such as TSMC and Globalfoundries. Currently, domestic manufacturers such as SMIC are Huawei’s foundry partners. However, the company plans to become self-sufficient in foundry operations with a series of government-backed deals in cities such as Shenzhen, Qingdao, and Quanzhou.

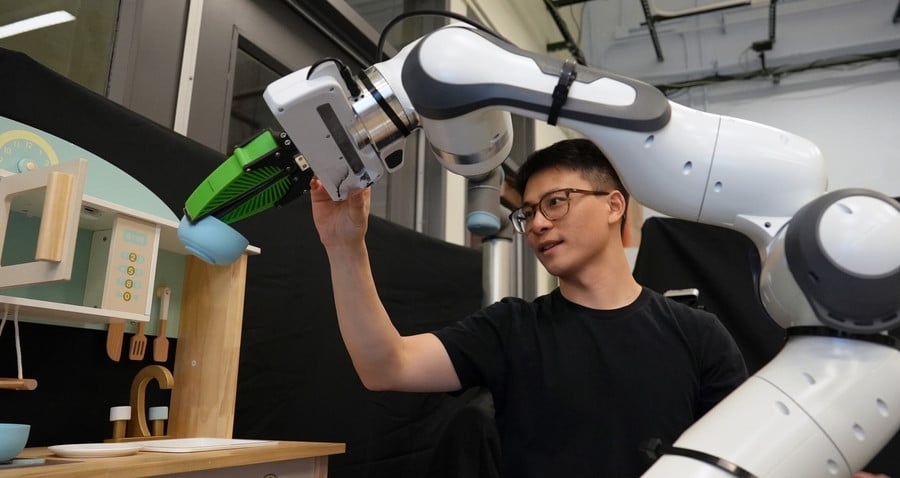

To attract high-quality workers to the center, Huawei is offering salaries that are double those of other domestic chipmakers, Nikkei Asia sources said. The tech giant has hired a large number of engineers who have worked for the world's leading chip foundry tool makers such as Applied Materials, Lam Research, KLA and ASML.

The export controls imposed by the US over the past few years have affected the mainland job market, with Chinese engineers finding it increasingly difficult to work for foreign chip companies, opening up opportunities for Huawei and domestic companies to attract talent.

However, industry executives say that despite the “generous” salary packages, the biggest challenge for engineers is work culture.

“The working environment is brutal. It’s no longer 996—9am to 9pm, six days a week—but 007—0am to 0am, seven days a week, no days off,” said a Chinese chip engineer. “Contracts are usually three years, but most don’t last until they’re renewed.”

Chinese foundries are now looking to domestic production equipment to replace imported semiconductors. Naura, the leading foundry equipment supplier in the mainland, has seen its revenue quadruple since 2018 and is expected to break another record in 2023.

Source

Comment (0)