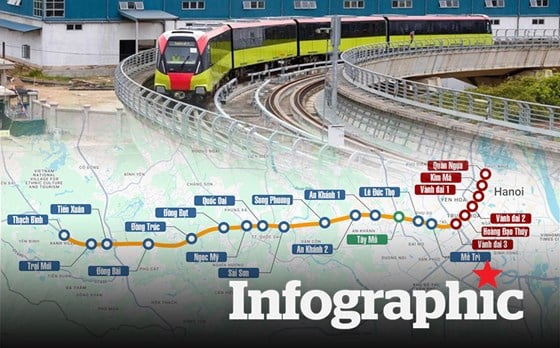

Two tunneling robots "Speed" and "Bold" are ready to drill 4 km underground of the Nhon - Hanoi Railway Station metro line.

On July 30, 2024, the TBM tunnel boring machine at the Nhon - Hanoi Railway Station Urban Railway Project (Metro Line 3 Hanoi) will officially start drilling the first meters of the project's tunnel.

|

| TBM Robot No. 1 "Speed" is ready to start drilling the Hanoi Metro Line 3 tunnel on July 30, 2024 |

After a long period of preparation, FECON Joint Stock Company - the contractor in charge of operating the Tunnel Boring Machine (TBM) said it is ready to operate the TBM robots deep underground.

According to the plan, the TBMs of the German manufacturer Herrenknecht named “Speed” and “Bold” will start drilling from station S9 (Kim Ma) to station S12 (Hanoi station) at the end of Tran Hung Dao street with a total length of 4 km at a depth of 17.8 m under the operation of a team of Vietnamese engineers and foreign experts.

FECON will operate TBM No. 1 named "Than Toc" to start drilling from Station S9 - Kim Ma. After a period of operating TBM No. 1, TBM No. 2 named "Tao Bold" will start drilling the second tunnel.

Each day, the TBM robot will drill about 10 m of tunnel, installing the tunnel lining as it drills. The waste volume during the tunnel excavation process will be collected and taken out of the construction site on a synchronized line.

|

| TBM consists of a digging shield and a rear auxiliary system with a total length of more than 100 m, manufactured by Herrenknecht (Germany). |

Mr. Nguyen Quoc Bao, Deputy General Director of FECON shared: “The tunnel construction technology using TBM machines at the Nhon - Hanoi Railway Station urban railway line is the world's leading advanced technology. Using the pressure balancing machine is very suitable for the geological conditions in Hanoi”.

The geology of Hanoi has many types of mixed soil and the tunnel route mainly runs in the clayey geological layer, which is more complex than the muddy clay soil like the Ben Thanh - Suoi Tien Metro project in Ho Chi Minh City. The Nhon - Hanoi Railway Station Metro project also constructs an underground section with a much longer length than the Ben Thanh - Suoi Tien Metro line.

In preparation for operating TBM robots at the Hanoi Metro Line 3 project, over the years, FECON has continuously sent key personnel to participate in training abroad under the guidance of leading experts from the World Underground Construction Association.

The total number of personnel for the construction work is more than 150 people. In which, the main tasks such as operating the TBM, operating the tunnel lining robot arm, replacing the cutting head, etc., FECON arranged experienced foreign personnel to coordinate with experienced engineers from the Metro Line 1 project in Ho Chi Minh City to directly carry out. In particular, the operations and maintenance of the TBM's auxiliary systems are all performed by Vietnamese personnel, who have been very knowledgeable about TBM equipment and machines throughout the past period.

|

| Tunnels and underground stations are one of the most important packages of the Hanoi Metro Line 3 project. |

“In addition to the experience accumulated and learned from the Ben Thanh - Suoi Tien Metro project, we have the construction and technical support from the expert team of Tunnel Pro, a leading TBM construction unit from Italy and the expert team from the International Underground Construction Association. All of these expert teams closely monitor the project, helping the project to be implemented more smoothly,” Mr. Nguyen Quoc Bao added.

|

| It is expected that each day, the TBM robot will drill about 10 m and install the tunnel lining at the same time. |

From the TBM Operator Contractor at the Metro Line 1 project in Ho Chi Minh City in 2017, FECON has become a Subcontractor undertaking most of the underground items at Metro Line 3 in Hanoi from 2017 to present. In this project, in addition to tunnel boring construction including the following work items: operating TBM tunnel boring machines, digging and installing tunnel linings; providing equipment and materials for tunnel boring; FECON has implemented other work items such as: Design and construction of retaining walls at the underground slope area, Construction of diaphragm walls for underground stations S9, S10 and S11, Construction of foundation treatment using large diameter high pressure grouting technology...

Package CP03 - tunnels and underground stations is one of the most important packages of the urban railway project No. 3, Nhon - Hanoi station section. The main scope of work of package CP03 includes: Double tunnel, monorail with an inner diameter of 5.7 m and a tunnel length of 2,573 m; underground stations including: Kim Ma Station (Station 09), Cat Linh Station (Station 10), Van Mieu Station (Station 11) and Hanoi Station (Station 12); Underground ramps; Turnaround area/Garage; Rescue shaft.

The main contractor of the CP03 package is the Hyundai - Ghella Joint Venture. The subcontractor FECON is the unit participating in assembling and operating the TBM tunnel boring robot.

The pair of TBM machines were specially designed for the urban railway project No. 3, Nhon - Hanoi station section. The machines were manufactured by Herrenkecht (Germany), are over 100 m long, and weigh about 850 tons.

TBM operates on the principle of soil pressure balance. Behind the excavation shield is a sealed baffle. Soil from the excavation shield will fall into the sealed chamber and create a pressure balance between the excavated soil and the unexcavated soil, making the excavation face stable and not collapsing. The soil pressure in the balance chamber is monitored by special devices placed directly in the machine body.

Source: https://baodautu.vn/hai-robot-dao-ham-than-toc-va-tao-bao-san-sang-khoan-4-km-ngam-tuyen-metro-nhon---ga-ha-noi-d220824.html

Comment (0)