TPO – A group of students from the University of Technical Education – Danang University have successfully created a dish press machine from environmentally friendly materials to replace plastic utensils.

TPO – A group of students from the University of Technical Education – Danang University have successfully created a dish press machine from environmentally friendly materials to replace plastic utensils.

|

Faced with the widespread use of non-biodegradable plastic products, which pose a risk of environmental pollution and impact on human health, a group of students from the University of Technical Education (University of Danang) have successfully created a dish press from areca spathe. This invention aims to create biodegradable products to replace traditional plastic utensils. |

|

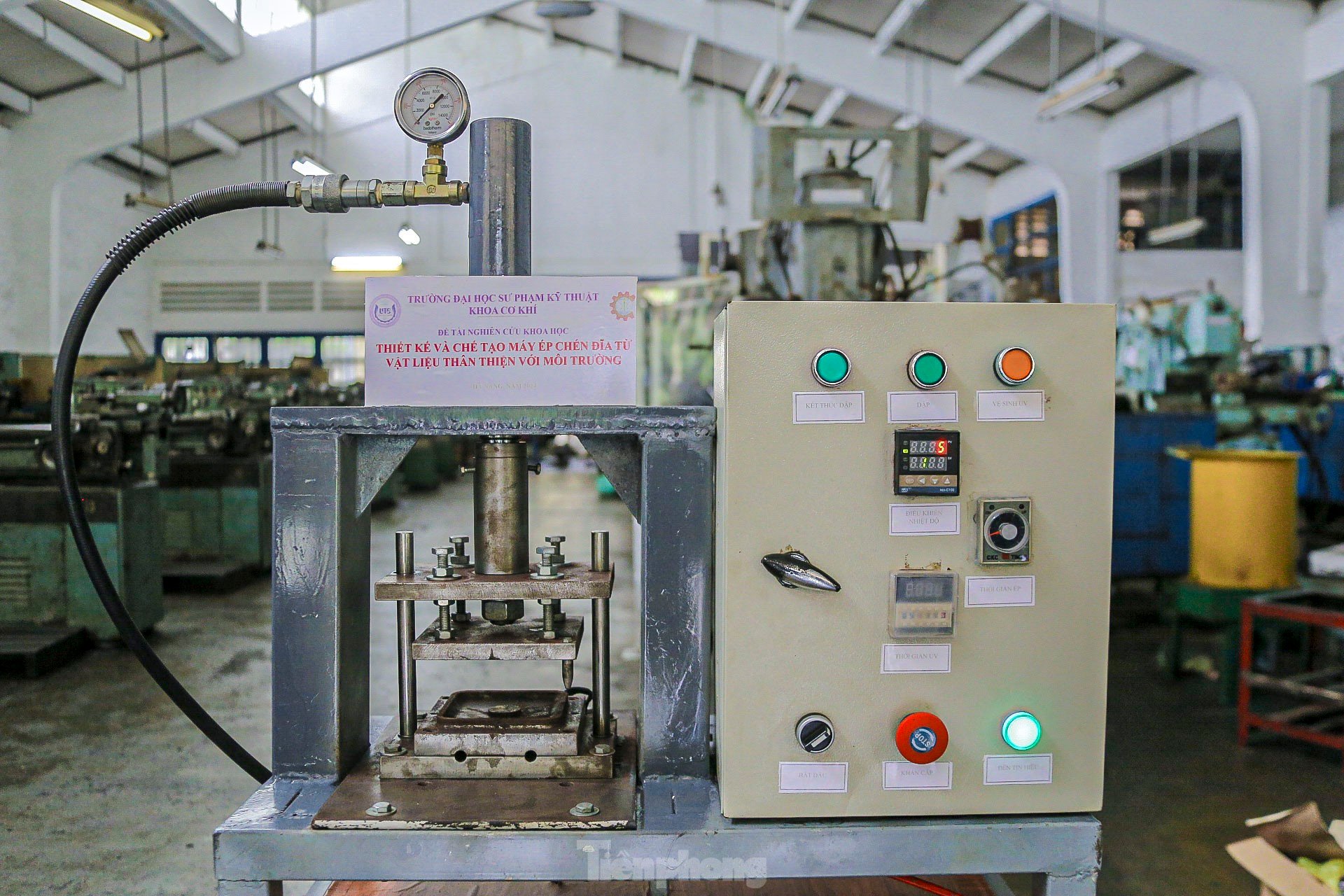

The research team includes students Le Van Tuan, Dang Huu Tai, Mai Xuan Son, Phan Tan Sang and Ho Van Ly (Faculty of Mechanical Engineering, University of Technical Education). Using hydraulic pressing technique with appropriate heating level, the team successfully manufactured a dish press from areca spathe, achieving a productivity of 60 products per hour. |

|

Sharing their ideas, the group members said that areca spathe is a biodegradable material, easy to find and suitable to replace plastic in the production of household items. Ho Van Ly, group representative, shared: “After many months of effort, we have completed a dish press machine from areca spathe. This achievement not only helps reduce environmental pollution but also helps the group win first prize at the school-level competition.” |

|

| The group of students won first prize in the school-level competition for scientific research. |

|

The machine is rectangular in shape, made of steel pipes joined together, 1.2m high, nearly 70cm wide, and weighs about 150kg. The machine has a hydraulic cylinder piston stamping unit, a mold to shape the dishes, along with controls and a cleaning system. |

|

When the button on the control panel is pressed, the heating system starts working and gradually heats up from ambient temperature to the desired temperature in the mold set at about 120 – 180 degrees Celsius in a period of 60 – 90 seconds. |

|

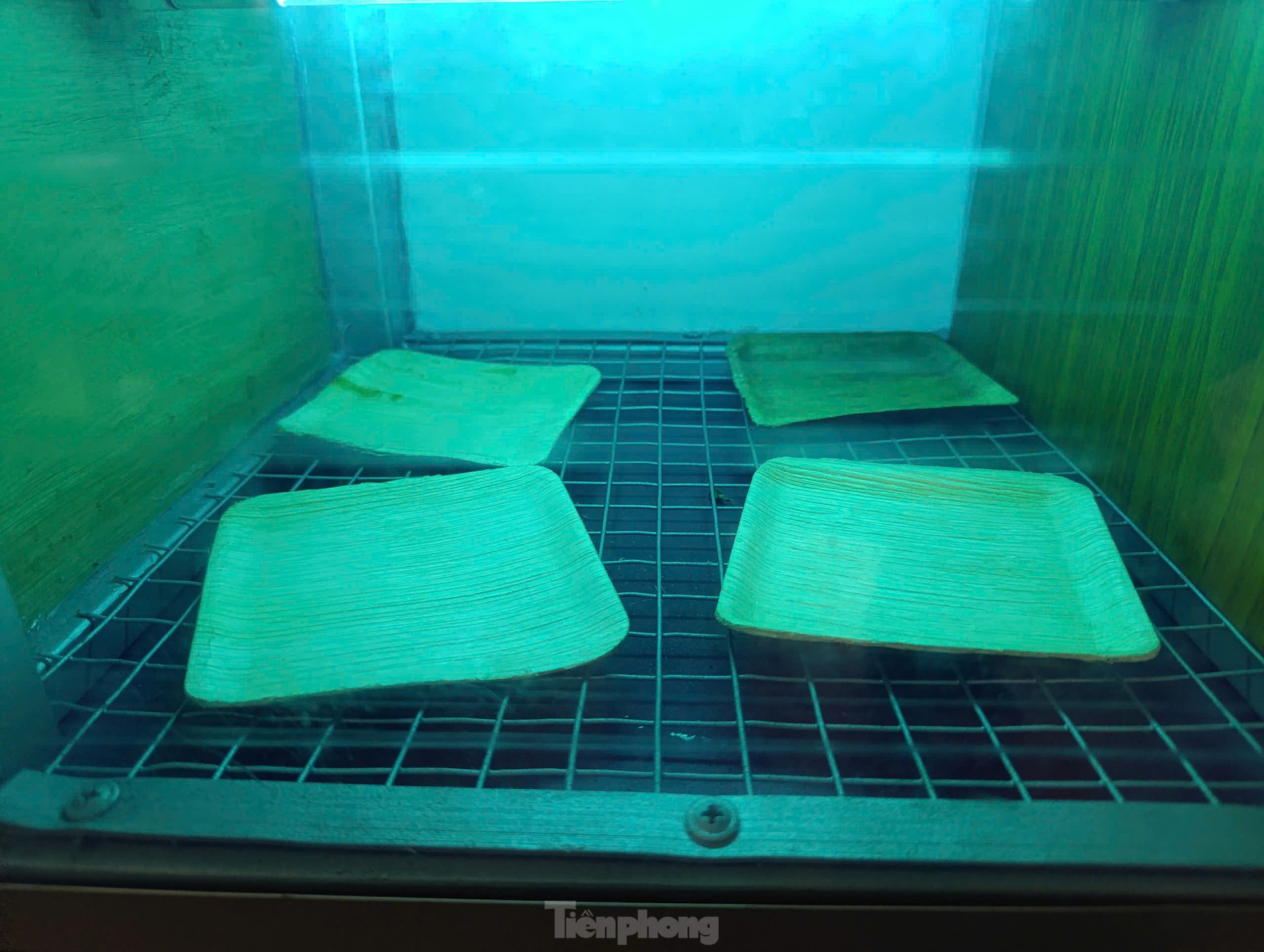

| This dish press uses heat treatment, product treatment using ultraviolet rays, UV cleaning to prevent mold. With a compact, aesthetic design and high safety. |

|

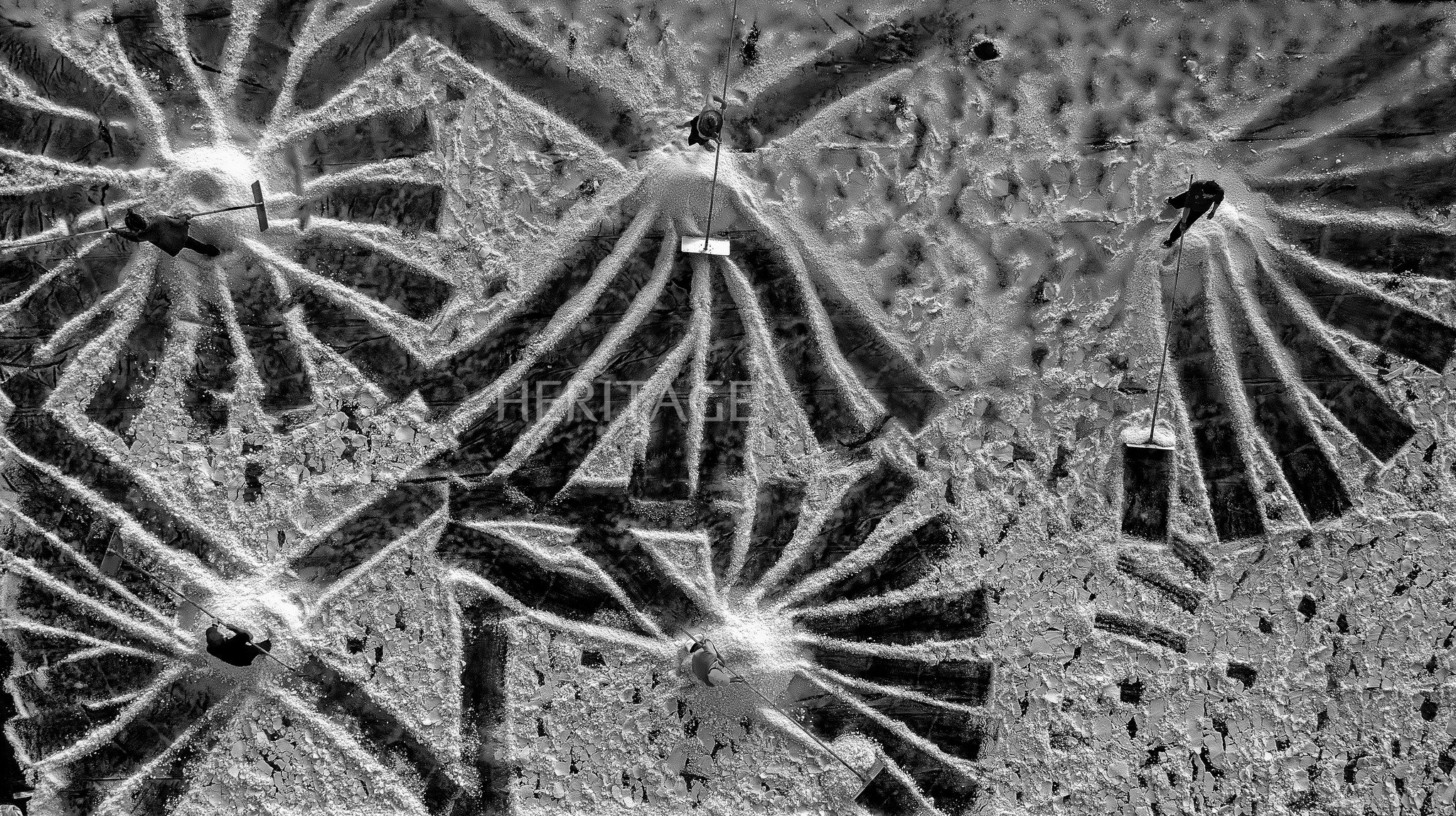

| The selected raw materials are areca spathe, lotus leaves, almond leaves... all types available in nature, favored by the export market, abundant raw materials are a potential for sustainable economic development. |

|

Dr. Bui He Thong – Lecturer of the Faculty of Mechanical Engineering – who guided the invention team, said that researching and designing a cup and plate pressing machine from available materials such as areca spathe, lotus leaves, and almond leaves, etc. is very practical. This invention not only helps solve the problem of green product consumption but also contributes to sustainable economic development and spreads a green lifestyle in the community. “I hope this product will be developed, expanded and applied in production in the future,” said Dr. Thong. |

Da Nang students invent a dishwashing machine from environmentally friendly materials. Video: VL |

Unique creative products of young students in Da Nang

Exciting New Student Festival of Danang University

'Drawing' a map to help new students in Da Nang find accommodation at the beginning of the school year

Comment (0)