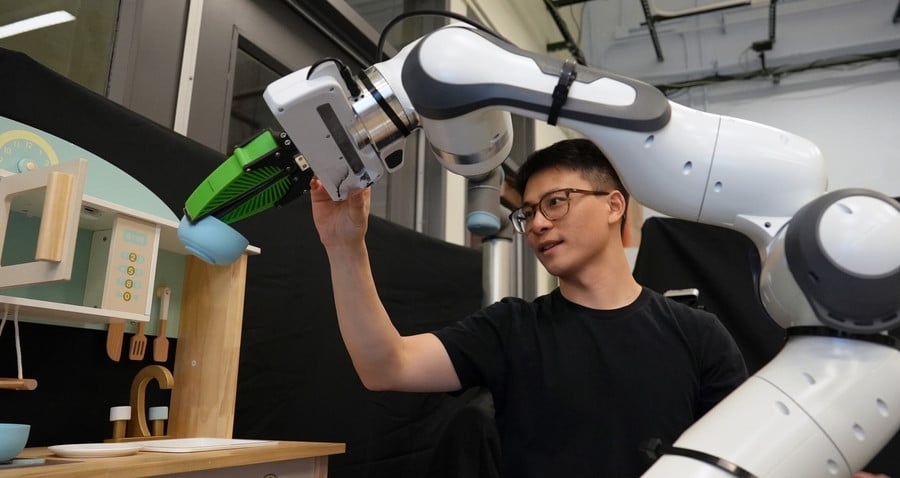

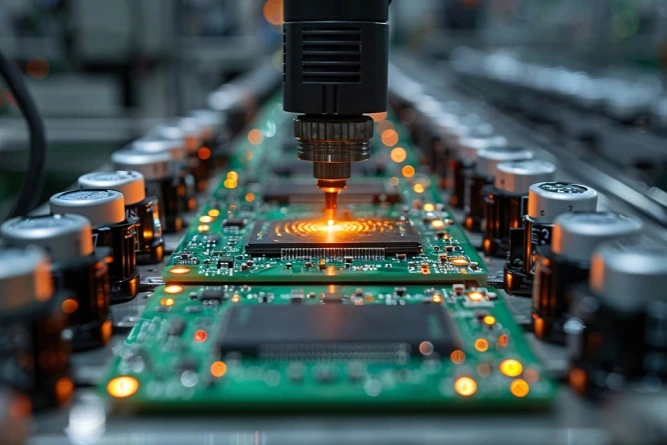

With the ability to analyze massive amounts of data and make intelligent decisions, AI is revolutionizing the way manufacturers operate and is starting to have a profound impact on the industry.

One area where AI is transforming manufacturing is predictive maintenance. Instead of relying on scheduled maintenance or repairs, AI algorithms can now predict when machines are likely to fail based on real-time data analysis.

By analyzing data from sensors and other sources, AI can identify pattern-based anomalies that indicate the likelihood of machine failure. Manufacturers can then schedule proactive maintenance, significantly reducing downtime and improving overall efficiency.

Quality control is another important area where AI is proving to be useful. With the ability to analyze large amounts of data quickly and accurately, AI algorithms can detect defects or irregularities in products with unprecedented accuracy.

Manual inspection, which can be time-consuming and prone to human error, is being replaced by automated quality control processes. This ensures that only products that meet the highest standards are released to market, improving customer satisfaction and reducing the costs associated with recalling or returning defective products.

AI is also reshaping supply chain management in manufacturing. By analyzing data from various sources such as sales forecasts, inventory levels, and supplier performance, AI algorithms optimize inventory management and demand forecasting.

Accurate demand forecasting helps manufacturers adjust inventory levels accordingly, minimizing overstocking and overstocking. This not only reduces production costs, but also improves customer satisfaction.

Additionally, AI identifies bottlenecks and inefficiencies in the supply chain, allowing manufacturers to make data-driven decisions to optimize logistics processes and reduce delivery times.

Furthermore, AI is driving improvements in energy efficiency and sustainability. By analyzing data, AI algorithms can identify energy consumption patterns and suggest optimization strategies. This includes adjusting production schedules to take advantage of off-peak energy levels and identifying areas where energy can be reduced without affecting productivity. Manufacturers can reduce their carbon footprint and lower their energy costs, thereby improving their bottom line.

The development of AI is radically changing the manufacturing industry. As AI continues to develop and become more sophisticated, its impact on the manufacturing industry will continue to grow.

AI is no longer just a buzzword, it could be a game-changer that revolutionizes manufacturing today and for years to come.

(according to IR)

OpenAI Apps Continue to Crash, Crashing Widespread

Several OpenAI products have been experiencing serious technical issues, leading to widespread outages over the past few days.

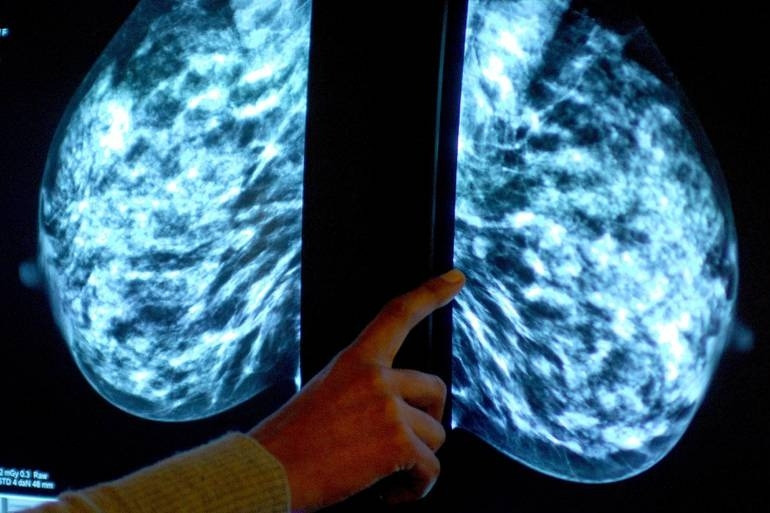

Developing AI device to predict cancer patient survival

Researchers have developed an artificial intelligence (AI) device that can comprehensively assess and personalize the treatment of patients with breast, thyroid and pancreatic cancer.

AI-powered computers will dominate the market after 2026, with a rate of more than 50%

Personal computers (PCs) using artificial intelligence (AI) will dominate the market after 2026 and reach a rate of more than 50%.

Source

Comment (0)