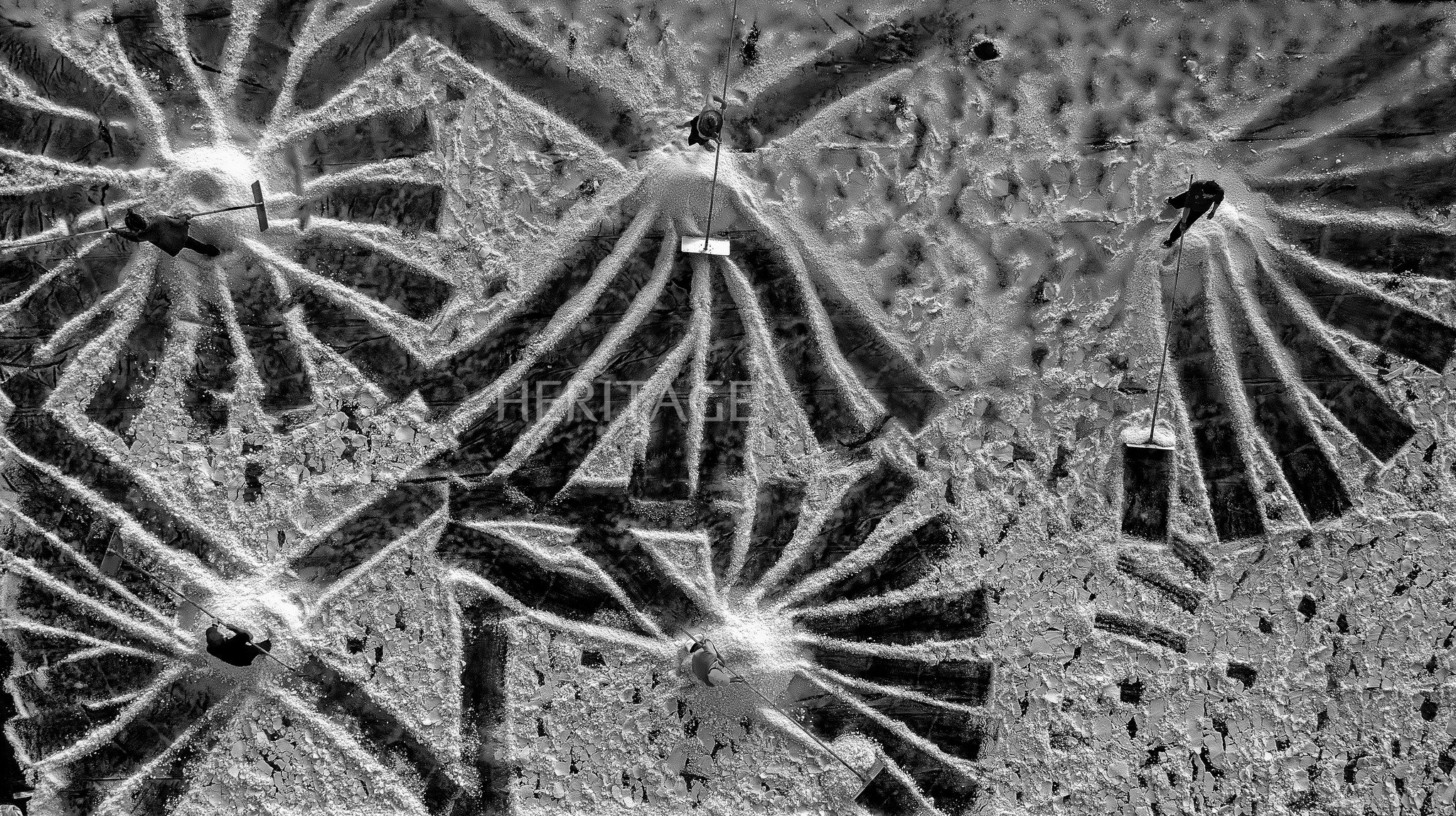

In 2025, Ha Tu Coal Joint Stock Company - Vinacomin was assigned by TKV to exploit 2.5 million tons of raw coal, excavating 44 million m3. soil and rock. To complete this task, one of the urgent tasks for Ha Tu Coal is to quickly process more than 2 million m3 Mud at the bottom of the North Bang Danh lake due to the impact of heavy storms in 2024.

Ha Tu Coal Joint Stock Company - Vinacomin has just gone through 2024 with many difficulties. Mining floors could not be expanded according to the annual plan, the order of mobilizing coal seams was changed; there was a lack of dumping area for soil and rock, affecting production progress. From the third quarter of 2024, heavy and prolonged rains, especially the impact of storm No. 3, devastated production floors, causing water and mud to increase. According to statistics at the time after storm No. 3, the volume of mud accumulated at the bottom of Bac Bang Danh mud of Ha Tu mine was over 2 million m3 . The concentration of human resources and equipment to pump out water and treat this amount of mud has interrupted the mine's coal production progress.

Mr. Tran Quoc Toan, Deputy Director of Ha Tu Coal Joint Stock Company - Vinacomin said: Facing those difficulties, with the close and drastic direction of the Group, the Company launched a 90-day and night production emulation plan to develop specific goals and solutions to complete the assigned tasks. By the end of 2024, the Company had completed 2.35 million tons of coal exploitation, equal to 87% of the plan at the beginning of the year and 100% of the Group's adjusted plan.

Identifying that the 2025 task will be more difficult when the remaining issues of 2024 have not been resolved, Ha Tu Coal has accelerated the progress of handling all stages of work. The important thing to do immediately is to take advantage of favorable weather conditions in the first months of the year, focus on machinery and equipment for dredging work, and completely handle the remaining volume of moong mud from 2024.

In January 2025, the Company completed dredging 650,000m3 . mud. After the Lunar New Year holiday, units focused on production again on the 4th day of Tet and maintained a bustling competitive atmosphere in the following days.

According to Mr. Nguyen Manh Hung, Head of the Company's Production Control Department, the process of treating moong mud is carried out in order from West to East to proceed with deep exploitation in the Western area according to the plan and exploitation diagram. In order to ensure the completion of moong mud treatment before March 15, 2025 as committed to the Group, in addition to using self-made equipment, the Company is still mobilizing equipment from outsourced partners to participate in the construction to speed up the progress of moong mud treatment. On average, the Company arranges 40 trucks with a load capacity of over 90 tons, 28 trucks with a load capacity of under 90 tons and 7 excavators to operate simultaneously to serve the dredging and transportation of mud from the bottom of the moong to the surface.

With the greatest effort, up to now, the Company has completed dredging nearly 2 million m3. mud at the bottom of the mine and is currently mining coal at the North Bang Danh mine. On average, the unit's daily coal output reaches 8,500 tons of coal.

In addition to the task of dredging and transporting mud, Than Ha Tu also implements storm prevention projects, especially drainage systems. Accordingly, the Company has implemented 28 projects serving drainage and storm prevention in 2025 according to plan. At the same time, the unit has also implemented the construction of self-flowing drainage systems around the Bac Bang Danh quarry. For the surface drainage system outside the quarry, the unit dredged settling pits inside and outside the quarry, consolidated dredging drainage ditches, consolidated drainage systems at waste dumps in Via Tru; at the same time, renovating working floors to lead water to the Company's surface drainage systems.

With the surface water collection area under the self-drainage belts, the Company has built a forced drainage plan with 3 options according to the specific surface water and groundwater volume flowing into the pit. The largest option will arrange 6 pumps with a capacity of 800-1,300m3 /h in the pit bottom area; the total amount of pumps mobilized is 14 pump systems with a capacity of 600-1,300m3 /h; the number of pump pipes mobilized is 2,500m.

Drawing on lessons from storm prevention in 2024, Ha Tu Coal is promoting a proactive spirit, preparing the best response plans to natural disasters; ensuring safety for production areas and completing the assigned output plan in 2025 with 2.5 million tons of raw coal.

Source

Comment (0)