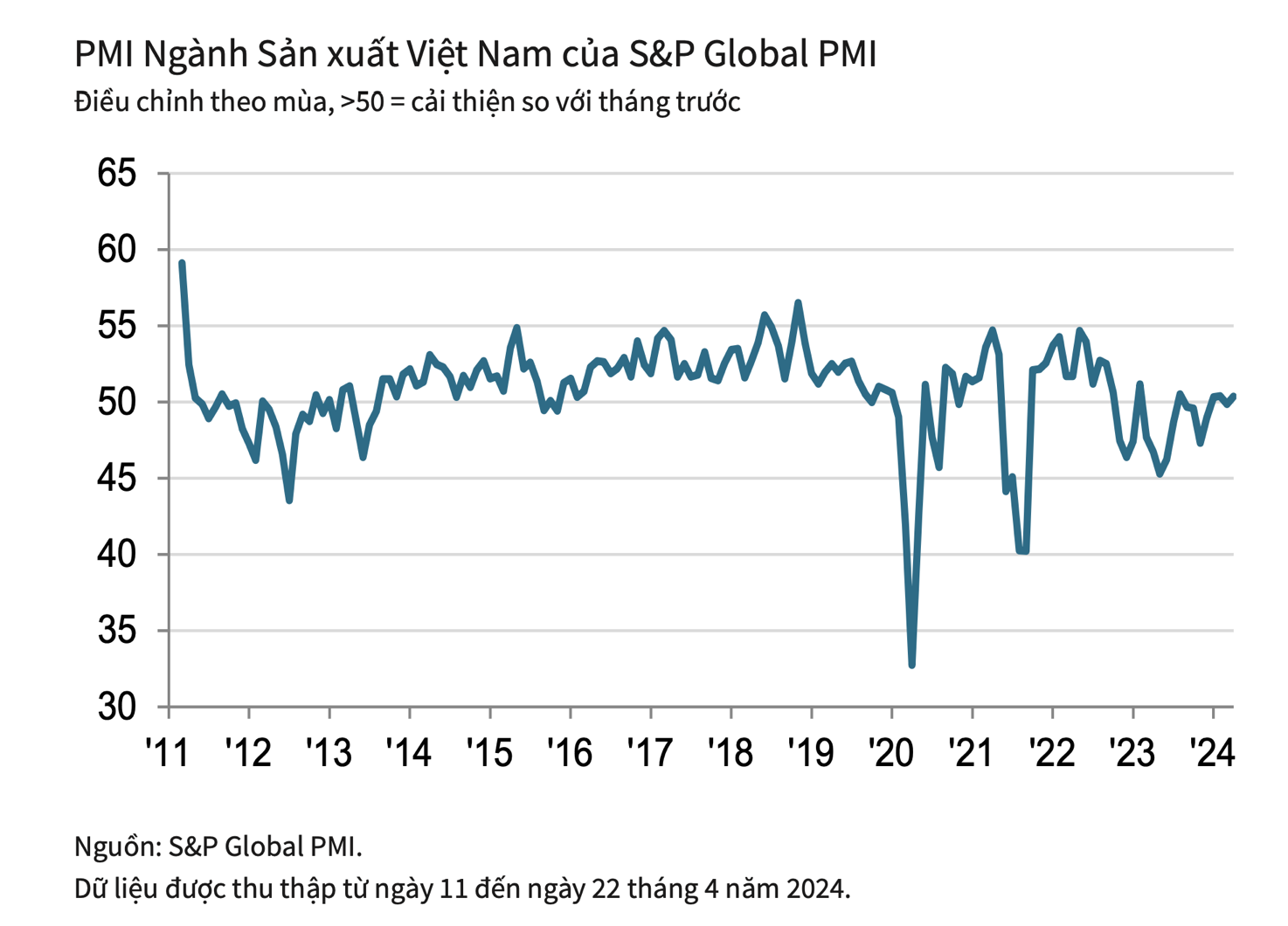

The latest S&P Global Purchasing Managers' Index (PMI) report shows that the Vietnam manufacturing PMI rose back above the 50-point threshold in April, at 50.3 points. Compared to the 49.9 points in March, the April PMI results show a slight improvement in the health of the Vietnamese manufacturing sector.

The positive points of this survey were a strong recovery in new orders, which increased at the fastest rate since August 2022. Panelists reported that market demand had improved and they had succeeded in attracting new customers.

In addition, the number of new export orders in April 2024 also increased slightly, but at a lower rate than the number of new orders. Another factor contributing to the increase in the number of new orders in April was the selling price of goods. Accordingly, the selling price of goods decreased for the second consecutive month in the context of businesses having to compete on price and meet the discount requirements of customers. Input costs continued to increase slightly in April due to higher oil, sugar and transportation costs.

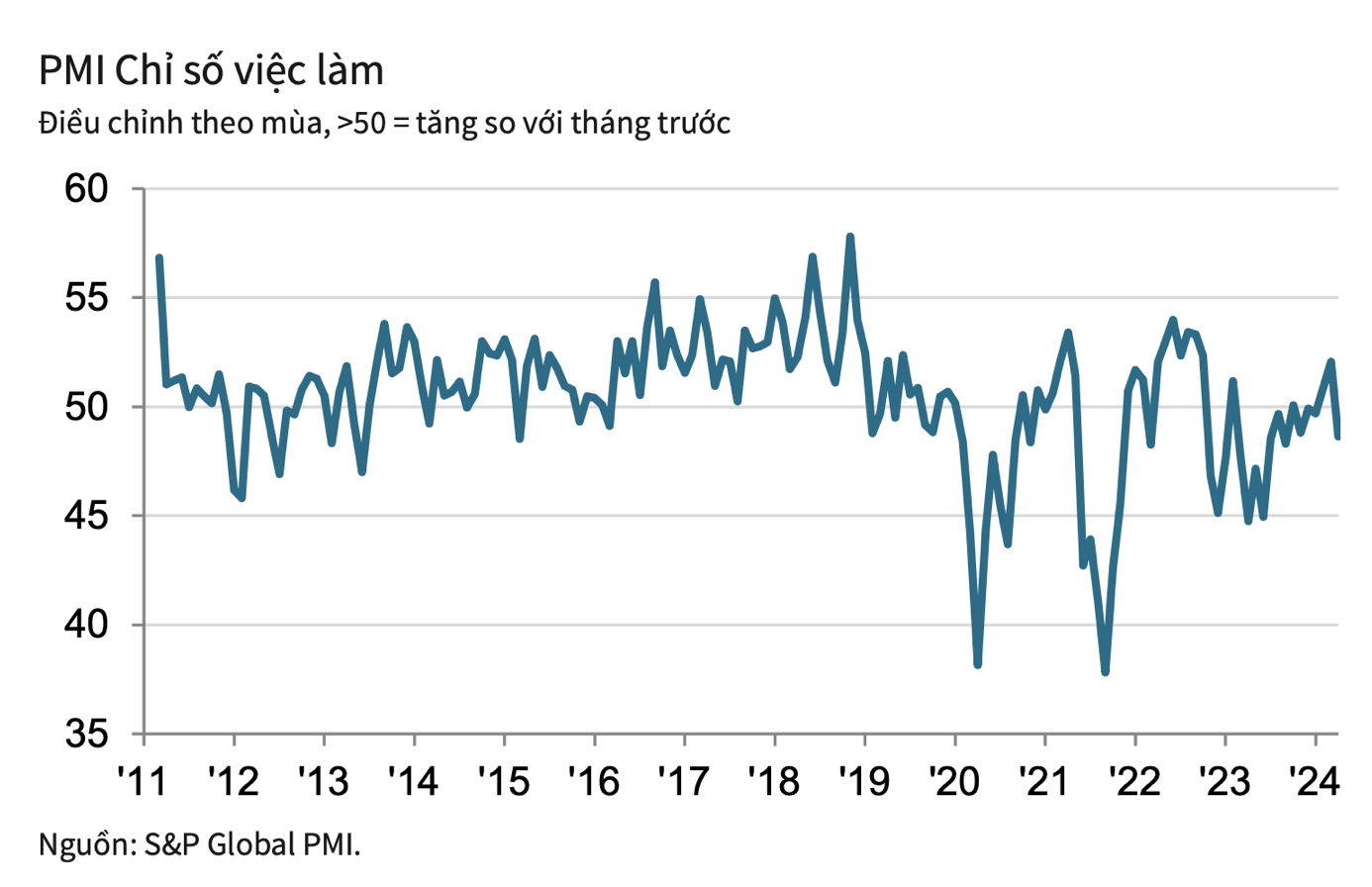

The report also said that a strong increase in new orders helped to drive a modest increase in manufacturing output in Vietnam. However, the current weak demand situation led to firms cutting jobs for the first time in three months. This made it difficult for firms to fulfil orders on time, leading to a slight increase in backlogs.

Commenting on Vietnam’s manufacturing sector in April, Andrew Harker, Chief Economist at S&P Global Market Intelligence, said that new orders in Vietnam’s manufacturing sector rebounded encouragingly in April after a period of weakness recently. There were also some signs that the pace of the rebound may have taken companies by surprise as they had decided to lay off workers following a period of reduced demand, leading to a rise in backlogs.

"We may see some of these workers return to work in the near future. More broadly, the recent ups and downs in new orders have left companies nervous about the future. Hopefully we can see a more stable environment in the coming months to help manufacturers plan output and prepare resources effectively," said Andrew Harker.

Source

![[Photo] Overcoming all difficulties, speeding up construction progress of Hoa Binh Hydropower Plant Expansion Project](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/12/bff04b551e98484c84d74c8faa3526e0)

![[Photo] Closing of the 11th Conference of the 13th Central Committee of the Communist Party of Vietnam](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/12/114b57fe6e9b4814a5ddfacf6dfe5b7f)

Comment (0)