Not yet able to become direct partners of the 'big guys', Vietnamese enterprises need to use the method of 'tying the ants' belts to find their way through the cave' - seeking opportunities from related suppliers to meet the conditions for producing aviation components.

Vietnam can be a Tier 4 supplier Boeing's forecast of global commercial aircraft demand shows that from now until 2043, the market will need about 44,000 aircraft; of which, narrow-body aircraft will be more than 33,380 and wide-body aircraft will be about 8,065. Thus, on average, the world will need 2,000 aircraft each year. However, currently, the average capacity of Boeing and Airbus - the two companies that account for 99% of total civil aircraft sales - can only supply 600-800 aircraft/year, with a maximum of 900 aircraft/year. With an average of 60-80 aircraft/month for Airbus and 35-45 aircraft/month for Boeing, experts say that capacity must be doubled to meet the demand of the global aviation market. The two "giants" Boeing and Airbus have many manufacturers in the supply chain, from large structures to small components and system integrators, aircraft assemblers. Mr. Duong Nguyen Thanh, Vice President of Giza Industrial Investment Holding Group, said that each year, 500-600 Airbus A320s are manufactured. Besides French, German, British, Spanish enterprises... specializing in manufacturing and supplying a variety of components and parts of aircraft. Chinese enterprises also participate in this supply chain, taking on the assembly and completion of aircraft (because many Chinese airlines require aircraft to be assembled and completed in this country). The structure of the aviation supply chain is divided into 6 levels: Level 1 - manufacturers of large components, large structures of aircraft such as airframes, propulsion engines... Level 2 - system integrators, software developers, assemblers of large structural assemblies, main assemblies of aircraft. Tier 3 - suppliers of specialized electronic components, power controls, wires, etc. Tier 4 - processing workshops/manufacturers of components according to available designs assigned by tier 1, 2, 3 companies. Tier 5 - distributors of components/materials/ancillary services such as screws, raw materials, adhesives, etc. Tier 6 - suppliers of raw materials (casting blanks, forgings, etc.) Commenting on the opportunities for Vietnamese enterprises, Mr. Duong Nguyen Thanh said that Vietnamese enterprises can become tier 4 suppliers, provided that all raw materials are designated by tier 1, 2, 3 suppliers or as designated by airlines. We need to build a qualified team to work with higher-level suppliers to enter the world aviation supply chain.

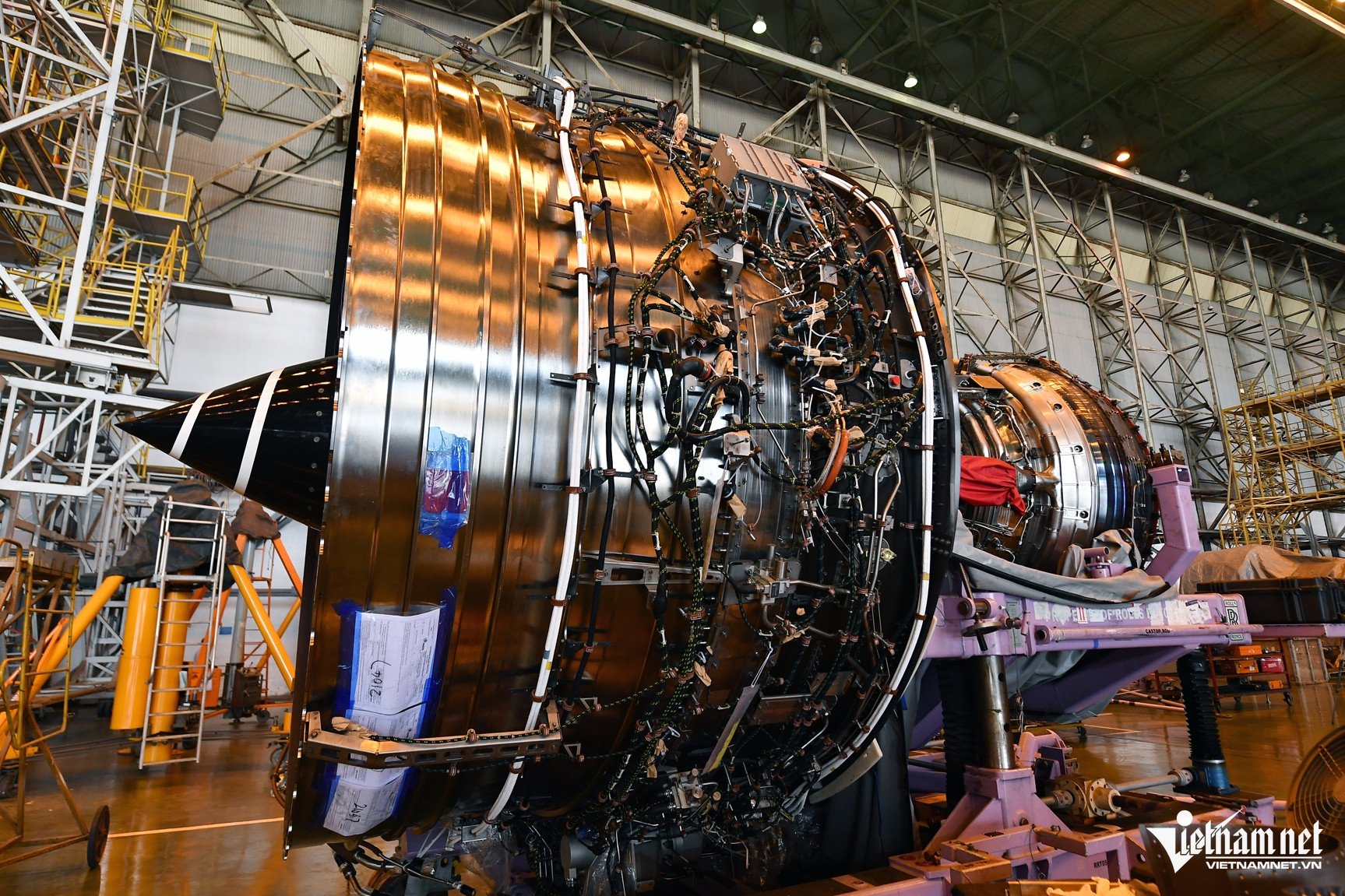

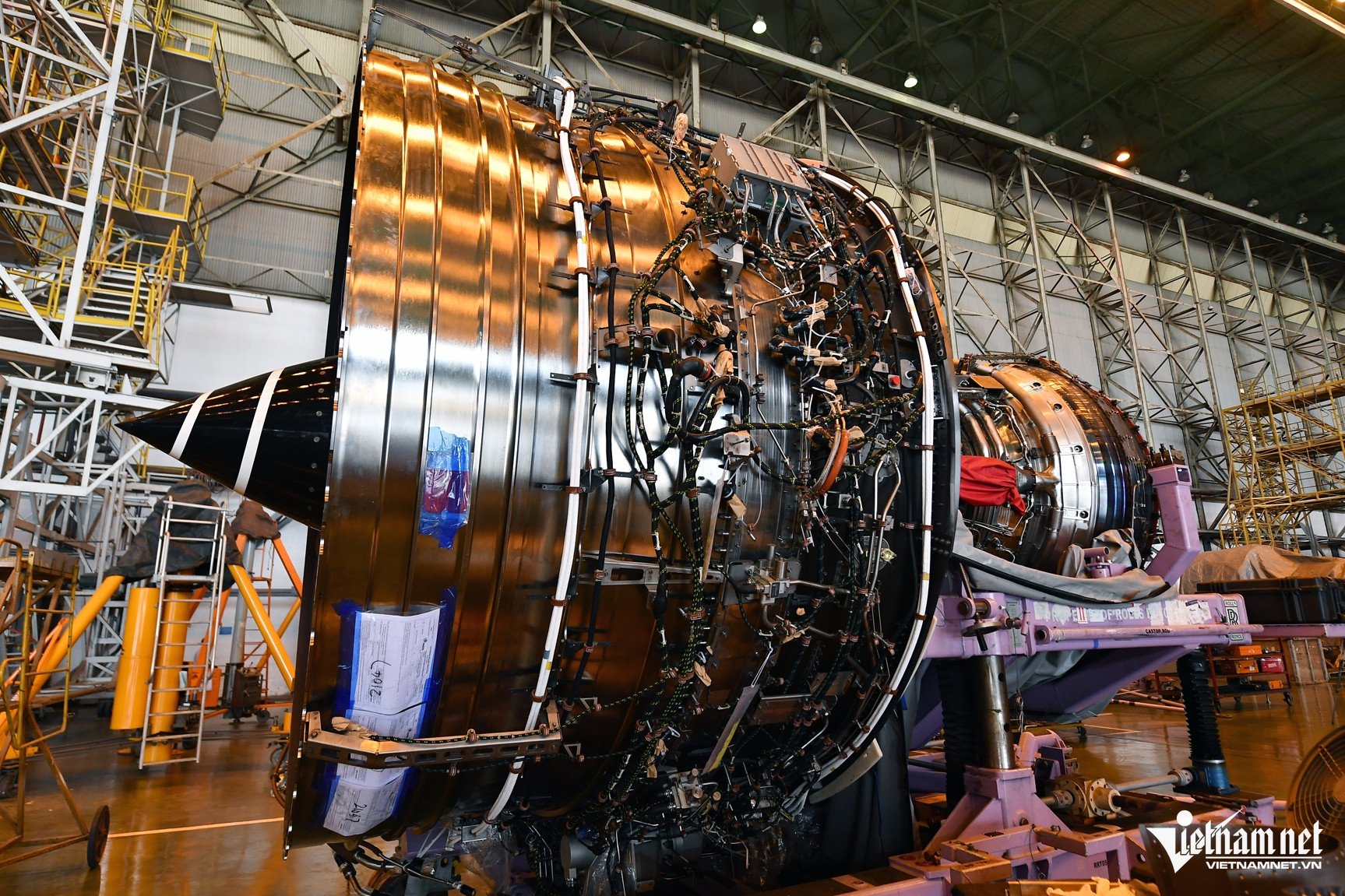

Vietnamese enterprises can become tier 4 suppliers in the overall aviation supply chain. Photo: Binh Minh.

Finding the 'door' to the aviation supply chain According to the Vice President of Giza, AS9100D - an international quality management system certificate for organizations providing products and services to the aerospace industry - is considered an "entrance ticket" for Vietnamese businesses that want to join the global aviation supply chain. "Having an AS9100D certificate does not mean you can make aviation components, but without this certificate, there is no 'door' to do it. There are some exceptions, but the purchasing companies will have to explain very strictly," said Mr. Thanh. However, to have an AS9100D certificate, one of the mandatory conditions is to "have produced components for the aviation industry" - which is not easy for most Vietnamese businesses. Sharing Giza's own story, Mr. Duong Nguyen Thanh said: "Although when investing in the factory, we determined to make aviation components, until now we have not officially sold any components. If only suppliers like Mitsubishi could give us some aircraft components to test our capabilities, it would be like 'tying a string to the back of an ant to find its way through a cave'. The products we make may not be used by the big guys to assemble new aircraft, but at least we have the qualifications of 'having produced aviation components' to build and complete the AS9100D standard system". The process of training a system to meet the AS9100D standard takes months, even years. Human resources play a key role in building and maintaining this system. "I talked to many aviation component manufacturers and found that now we can buy high-quality machines and modern equipment, but if we cannot maintain a stable workforce with deep expertise and proper training, it will be difficult to operate according to the AS9100D standard", Mr. Thanh said. Characteristics of the global aviation supply chain: Component manufacturers must be prepared to engage with international customers.

According to Boeing's representative in Vietnam, each plane needs more than 6 million different components; of which 50% are small supplies and screws. Photo: Nam Khanh

Vietnamese enterprises need to proactively create products and product groups that they think the "big guys" in the aviation industry will need. If they cannot produce goods according to requirements, they need to boldly design samples, test products, conduct tests on materials, functions, etc., and then introduce their capabilities to international partners. Many companies/enterprises that have a firm foothold in the global aviation supply chain are willing to train Vietnamese enterprises on management and support their staff, from the ability to read drawings, understand regulations, to knowing how to maintain international standards and certificates. However, Mr. Thanh also recommends that if you do not have a long-term plan for aviation, it is best not to enter this industry. The lifespan of an aircraft is 20-25 years, and equipment replacement is carried out throughout the life of the aircraft, meaning that today, if you produce components for the aviation industry, 20-25 years later, you still have to ensure that customers come to you to produce components for them. According to him, many tasks seem easy, but when you start doing them, you will face a series of difficult problems in terms of physics, technology, standards, aesthetics, etc., causing Vietnamese businesses to lose sleep for a long time. Global corporations/companies have a lot to learn. If you can cooperate with them, Vietnamese businesses will have a very large market and the production and business system will be qualified to do many other things. From Giza's experience, Mr. Thanh shared tips to help "newbies" find orders from international partners: "Search for businesses in the Top 500, Top 1000, Top 2000 of the world, connect with them through many channels such as email; Thanks to the system of counselors, trade embassies in Vietnam, companies, associations, chambers of commerce in Europe, America, Japan, Korea,... or if possible, actively ask the patriotic overseas Vietnamese team working in large companies for support.Vietnamnet.vn

Source: https://vietnamnet.vn/mot-chiec-may-bay-can-hon-6-trieu-linh-kien-cua-nao-cho-doanh-nghiep-viet-2324834.html

![[Photo] Prime Minister Pham Minh Chinh chairs Government Conference with localities on economic growth](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/2/21/f34583484f2643a2a2b72168a0d64baa)

Comment (0)