Requirements for green criteria in products and production force domestic textile and garment enterprises to transform to maintain their position in the export market.

The story of a pioneering business

According to Ms. Nguyen Thi Minh Hai - Head of Sustainable Development Department, Bac Giang Garment Corporation (LGG), like other textile and garment exporting enterprises, LGG is part of the global textile and garment supply chain. Greening standards set by importers are increasingly strict, requiring businesses to have a higher level of awareness and responsibility towards the environment and society.

From the very beginning, when building a new project, the company focused on investing in building a solar energy system, using renewable energy sources. Up to now, 40% of the electricity consumed by the entire factory is solar energy.

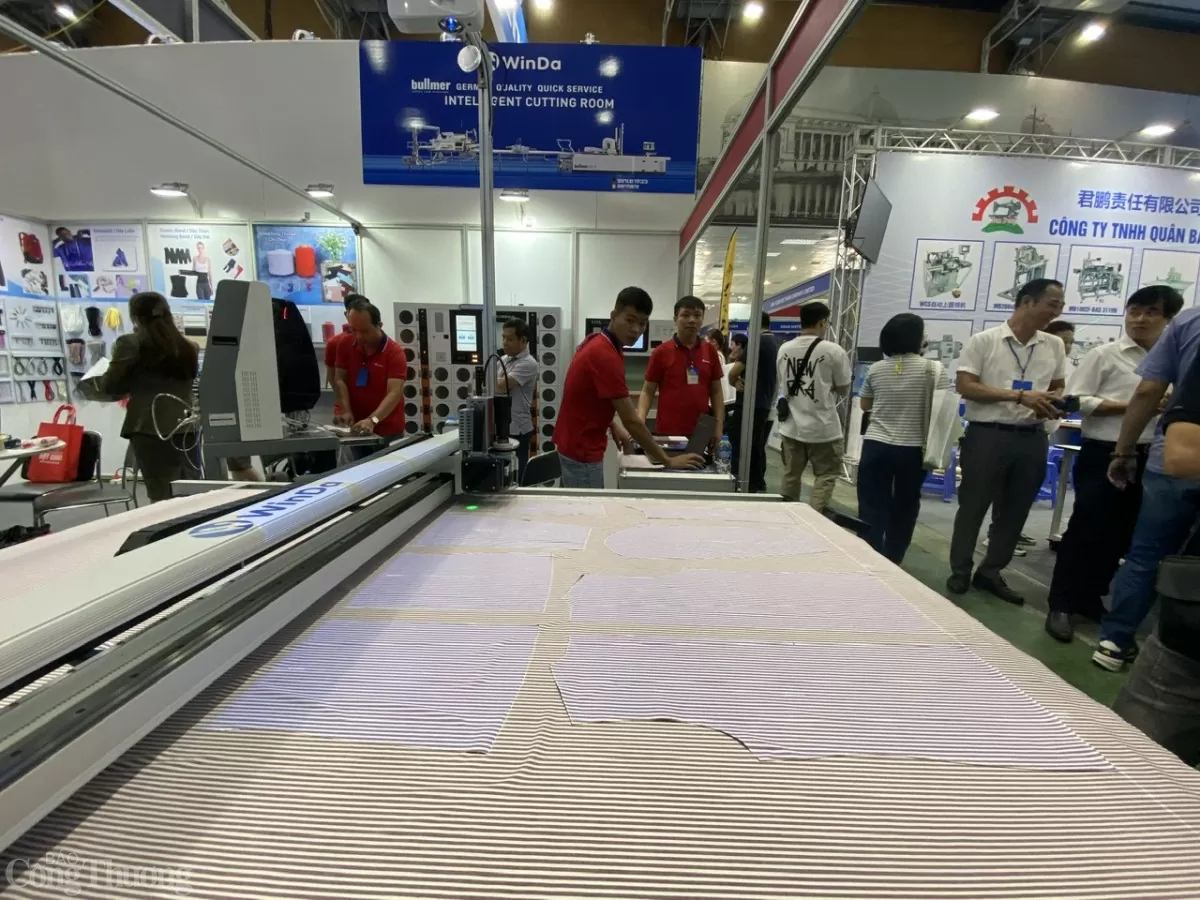

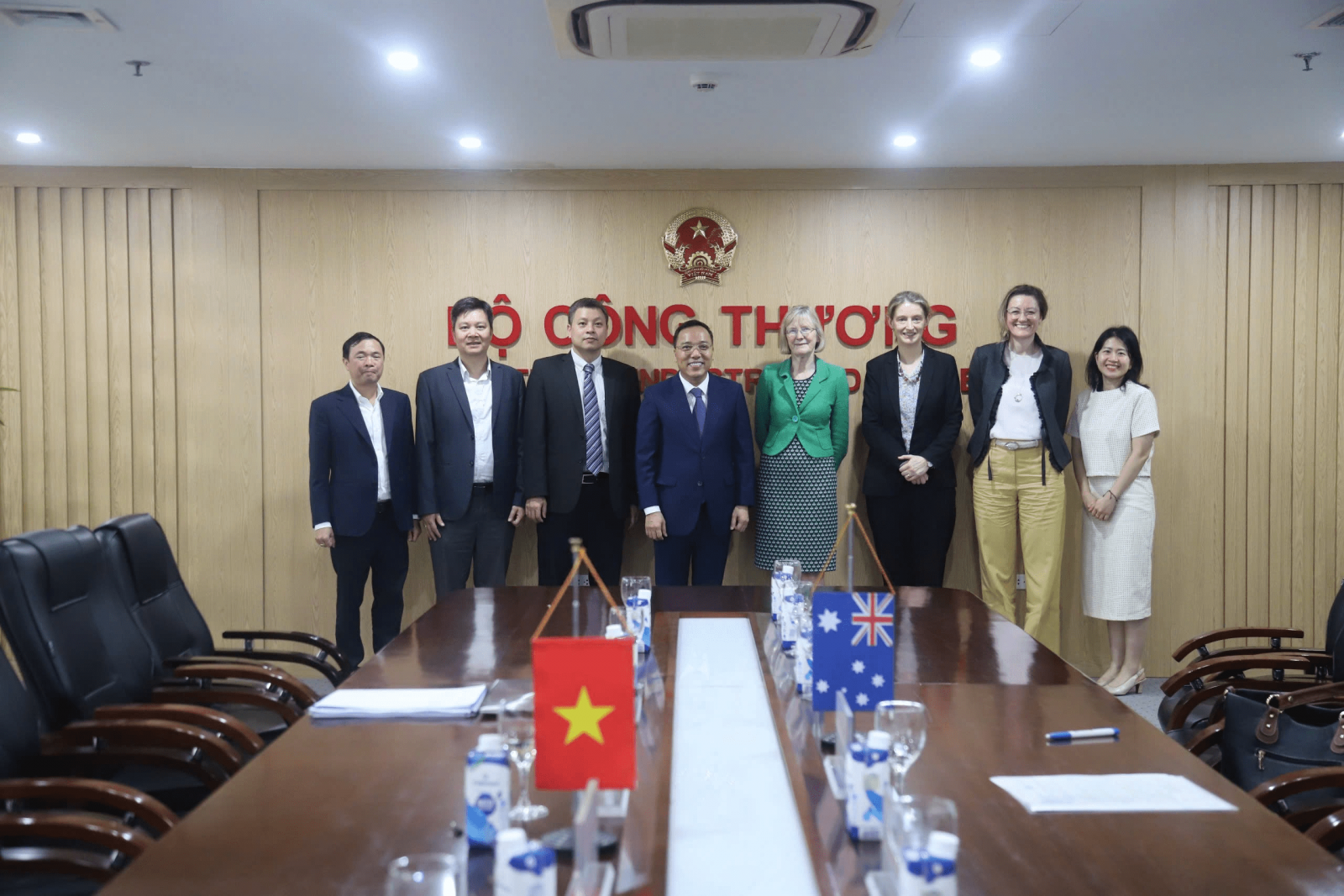

|

| Applying modern technological equipment is an important factor "promoting" the green transformation process of textile and garment enterprises. Photo: Hai Linh |

In addition, LGG also uses energy-saving measures, such as converting the entire previous fluorescent lighting system to LED lighting systems or having energy-saving policies to disseminate to all staff and workers; switching from using coal-fired boilers to clean biomass fuel boilers; using more environmentally friendly chemicals and ensuring safety for workers; the factory's wastewater output can be reused.

The factory also focuses on assessing global recycling certificates, certificates for the use of recycled materials or responsible feather certificates and many other social responsibility certificates that customers require during their participation in the supply chain and a series of activities to raise awareness of employees.

“ When participating in the green supply chain as well as implementing green development and sustainable development activities, the first benefit we see is that businesses save a lot of costs. At the same time, the level of recognition and position of the business is also improved, and the competitiveness compared to other businesses is also highly appreciated by customers, ” said Ms. Hai.

Not only LGG, facing the requirements for sustainable growth of import markets, the domestic textile and garment business community has actively and proactively transformed green production. Typical examples include May 10, May Phong Phu, May Viet Tien, May Duc Giang...

Regarding May 10, Mr. Than Duc Viet - General Director of May 10 Corporation - Joint Stock Company said that in the past 3 years, May 10 has implemented many green production activities such as investing in modern machinery and equipment, using less electricity; investing in solar energy systems, rooftop solar panels; linking production chains in Vietnam and abroad to make the most use of recycled products, from nature...

“ Greening production is no longer a matter of choice but has become a mandatory requirement for businesses to move towards sustainable exports. Even in the production process, coal-fired input fuels are being converted to biomass-fired fuels to ensure the lowest carbon emissions. It is expected that in 2024, if the entire May 10 project comes into operation, it will help reduce more than 20,000 tons of carbon emissions into the environment ,” Mr. Viet emphasized.

Overcoming difficulties for long-term goals

Although they have proactively made green transitions in production and business, businesses are still facing many challenges in this work, even large-scale businesses.

Ms. Hai identified that the first difficulty for businesses is capital. Investment capital for green development projects requires a lot of capital, for example, solar energy systems, wastewater treatment systems or systems using recycled materials all require a lot of capital.

The second difficulty is that the technical level and technological capacity of workers are still limited, especially in new fields such as renewable energy, solar energy, and wind power.

The third difficulty is the guidance and specific steps of state agencies for businesses, so that businesses have clear roadmaps in implementing green goals.

From the perspective of a consulting unit, Mr. Le Xuan Thinh - Director of Vietnam Cleaner Production Center Co., Ltd. - pointed out that the green transformation of textile and garment enterprises also faces many challenges. In particular, functional units have developed policies in this field, but specific guidelines and standards are currently not available, so enterprises are confused in implementation.

Besides, financial institutions and banks lend green capital, but most textile and garment enterprises in the value chain are small and medium-sized, facing difficulties in building financial profiles to access this capital source.

To help domestic textile and garment enterprises overcome the above difficulties and move quickly on the path of green transformation, Mr. Thinh proposed that in terms of policy, there is a Law on Environmental Protection with accompanying Decrees and Circulars guiding implementation, but there are no specific standards, such as green standards for the textile and garment industry, or there is a lack of guidance documents for enterprises to be able to implement the roadmap. In addition, there should be incentives in terms of financial mechanisms, such as incentives on capital, taxes, and access to science and technology for enterprises to implement green.

Support is needed, especially from industry associations, to build the workforce for the green transition.

On the business side, it is necessary to prepare a roadmap towards green transformation. This roadmap, in addition to being suitable for the capacity, also needs to demonstrate strong commitment in the implementation process from leaders to employees.

Source: https://congthuong.vn/doanh-nghiep-det-may-chu-dong-chuyen-doi-xanh-355683.html

![[Photo] Looking back at the impressive moments of the Vietnamese rescue team in Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/5623ca902a934e19b604c718265249d0)

![[Photo] "Beauties" participate in the parade rehearsal at Bien Hoa airport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/155502af3384431e918de0e2e585d13a)

![[Photo] Summary of parade practice in preparation for the April 30th celebration](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/78cfee0f2cc045b387ff1a4362b5950f)

Comment (0)