Inauguration of 50,000-ton Wharf and export of first shipments of the year of the Snake 2025

Specifically, on the first day of the year of At Ty 2025, THILOGI (THACO) held the inauguration ceremony of the 50,000-ton wharf, Chu Lai international port.

The completed wharf No. 2 (50,000-ton wharf) is a 365m extension downstream, connecting to wharf No. 1, increasing the total length of Chu Lai port to 836m, the depth in front of the wharf reaches minus 11.6m, ensuring the reception of general cargo ships and container ships with a capacity of up to 50,000 tons.

At the same time, it has invested in installing a modern specialized container loading and unloading crane system such as 2 STS gantry cranes with an investment cost of more than 300 billion VND, and 3 RTG frame cranes for the port yard with a cost of nearly 100 billion VND, along with a large number of specialized vehicles for internal port transportation. The synchronous investment in infrastructure and equipment will increase the loading and unloading capacity to nearly 100 containers/hour, 3 times higher than that of port No. 1.

Previously, on March 7, 2024, the People's Committee of Quang Nam province issued a Decision approving the investment policy and approving the investor for the project to expand and upgrade Chu Lai port, part of Tam Hiep port area, with a total investment capital of VND 1,590 billion.

Chu Lai International Port is a class 1 seaport according to the Master Plan for the Development of Vietnam's Seaport System for the 2021-2030 period, with a vision to 2050, approved by the Prime Minister. In order to develop the port commensurate with the scale and cargo output, the People's Committee of Quang Nam province has approved the Outline of tasks and estimates for surveying and planning the development of Chu Lai seaport towards 2030.

Also on the first day of the year of the Snake, more than 300 containers of goods from THACO member corporations were exported through Chu Lai port to the international market.

The large export shipment at the beginning of the year has affirmed the production capacity and product quality of THACO's member corporations, while demonstrating the determination to participate deeply in the global value chain, making THACO a leading multi-industry industrial corporation in the ASEAN region.

THACO inaugurates 50,000-ton Wharf, Chu Lai International Port and exports first shipments of the Year of the Snake 2025 - Photo: VGP/Nhat Anh

Inauguration of THACO INDUSTRIES R&D Center and auto parts manufacturing factories

Specifically, the THACO INDUSTRIES R&D Center is built on an area of 30,000 m2, including: Design Center; Material Testing and Product Testing Center; Sample Production Workshop and Multi-purpose Hall, with a total investment of nearly 40 million USD. The Center is invested with a system of modern laboratory and testing equipment, such as metal micro-analysis equipment, light transmission testing equipment, color uniformity measuring equipment on plastic substrates, CMM measuring equipment and advanced design and simulation software, along with a team of more than 1,000 experienced experts and engineers to implement product development strategies, meeting the needs of THACO member corporations, domestic and export partners.

The factory producing auto body frame components is built on an area of 15,000 m2, with a total investment of 30 million USD, with modern equipment and technological lines, with a capacity of 50,000 sets of stamped truck cabin components, 5,000 sets of buses, 200,000 sets of passenger car bodies and 500,000 sets of other mechanical stamped components/year. And chassis stamping equipment for light trucks to heavy trucks and tractors, with a stamping force of 6,300 tons, along with a welding line, chassis assembly, with a capacity of 50,000 sets/year.

The high-end auto glass factory is built on an area of 15,000 m2, with a total investment of 25 million USD. Of which, the passenger car glass factory has a capacity of 300,000 sets/year, and the truck and bus glass factory has a capacity of 150,000 sets/year.

The automobile electrical equipment factory is built on an area of 20,000 m2, with a total investment of 20 million USD, with a capacity of 150,000 sets of electrical wires and 50,000 sets of components and electronic equipment for passenger cars per year.

The auto parts manufacturing factories put into operation will contribute to the formation of a regional auto parts manufacturing center, along with the new R&D center and the Mechanical Engineering Center, affirming THACO INDUSTRIES' pioneering role in developing the Mechanical Engineering and Supporting Industry sectors in Vietnam and deeply participating in the global value chain.

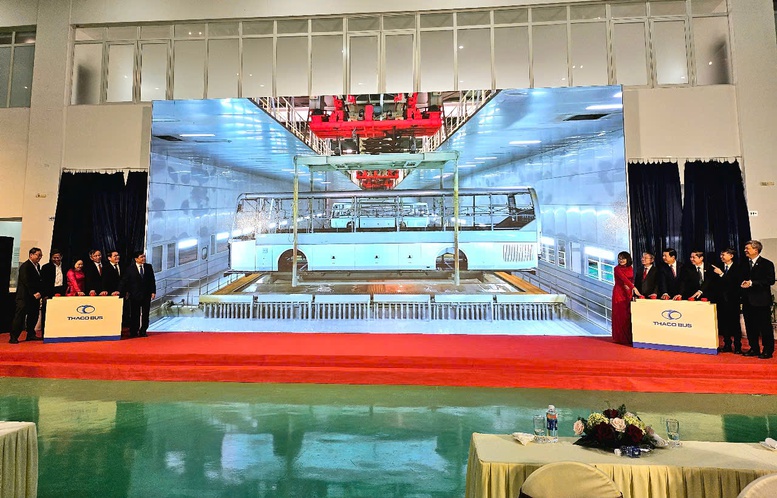

Inauguration of THACO Bus factory's production line - Photo: VGP/Nhat Anh

Inauguration of THACO Bus factory production line

To meet the increasing demands of domestic and export customers, THACO has invested in and upgraded the THACO Bus factory with a modern, automated, intelligent production line, open connection with green space inside and outside the factory.

In particular, the welding workshop is invested with a chassis production line & automatic welding robot system combined with laser cutting equipment for steel plates and steel boxes, ensuring production from separate components to finished bodies. The electrostatic painting line can dip products up to 13.7m long. The assembly workshop with new generation bus production technology, integrated with an additional production line for interior components ensures synchronization, flexibility, convenience for component distribution and optimizes production costs.

THACO Bus Factory has put into operation the SCADA system to check and monitor production activities on each line and will continue to promote digital transformation by putting into operation the MES production operating system, ERP resource integration management system, gradually forming a smart factory, meeting production requirements according to the specific requirements of domestic and export customers.

THACO Group's leaders affirmed that THACO's investment projects in Chu Lai inaugurated in the early spring of At Ty 2025 are driving projects, contributing to realizing the orientations according to the Quang Nam Provincial Planning for the period 2021 - 2030, which are: promoting the development of the automobile manufacturing and assembly industry, mechanical, electrical and electronic products; forming a national multi-purpose mechanical and automobile center; developing supporting industries associated with logistics services, seaport, airport and railway logistics; creating a driving force to promote the economy in the Central region, contributing to the industrialization and modernization of the country.

Source: https://baochinhphu.vn/thaco-khanh-thanh-nhieu-du-an-dong-luc-trong-ngay-ra-quan-san-xuat-dau-nam-at-ty-102250203163033594.htm

Comment (0)