Leading in manufacturing automated production lines

"To achieve the above goal, our company focuses on researching and developing many types of automation lines with diverse sizes and installing and transferring new technology applications and new lines to businesses," shared engineer Nguyen Hoang Lan, Deputy Director of Fuji Machinery Manufacturing Co., Ltd.

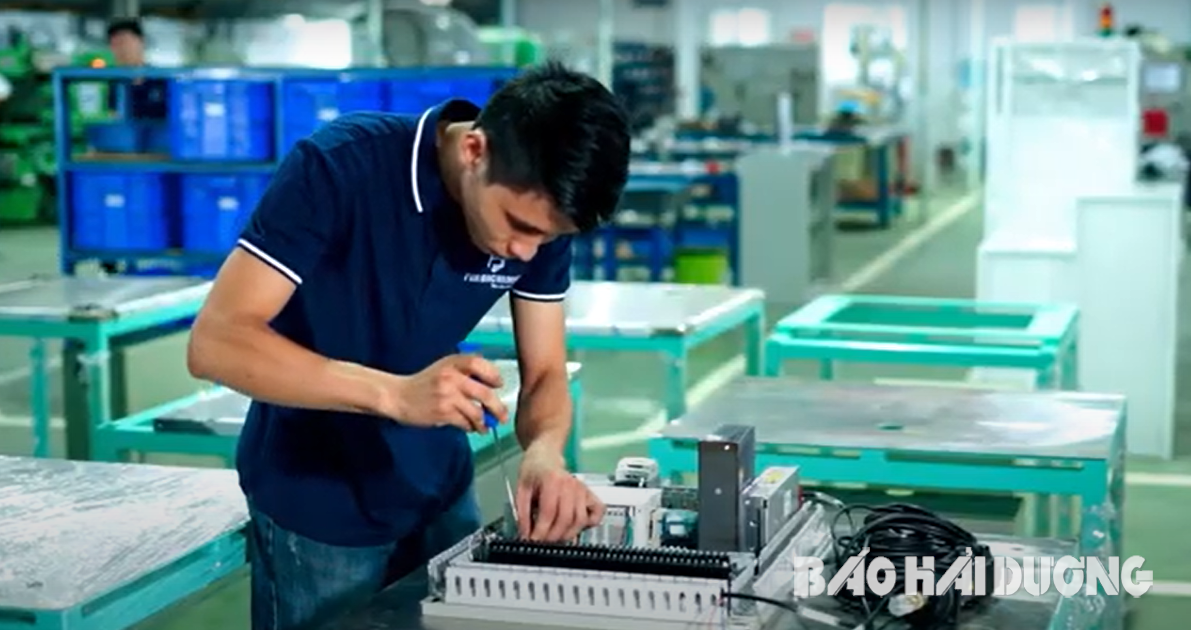

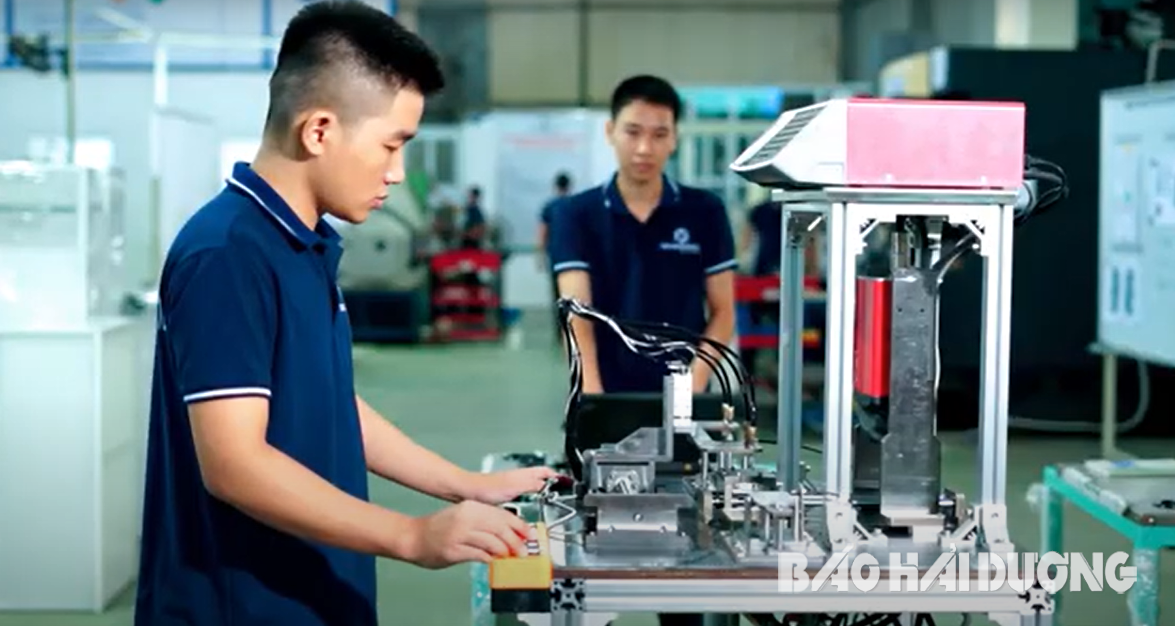

The company currently has 12 engineers and 6 skilled technicians. Born in 1990, engineer Mai Van Son, Head of Production Department, has joined and worked with the company for 5 years. Over the past 5 years, he and his technical colleagues in the department have researched and developed many useful products. A typical example is the oil tank cleaning machine used to automatically remove metal chips and sludge, helping to clean oil tanks of mechanical processing centers, CNC machine tools and technical equipment. The machine is compact in size, easy to use, helping to save time and production costs for businesses. Another product of the company that is also highly appreciated by many partners is the automatic oil filter and recovery machine used in metal processing. This machine helps increase machine life, improve labor productivity, ensure industrial hygiene, protect workers' health and reduce emissions to the environment. Or hydraulic metal chip pressing system with intelligent control mode, low operating and maintenance costs, ensuring improved 5S operation quality...

In 2023 alone, Fuji Machinery Manufacturing Co., Ltd. focused on perfecting and transferring many new technology products, typically the Super Hijet- Musashi Engineering automatic glue pump equipped with the function of spraying solution into the set position with high precision; dot-type marking technology (also known as Dot Peen marking technology) helps create permanent, anti-counterfeit, highly durable marks on all types of materials and parts...

"Our products are all aimed at solving problems in our customers' production processes. We develop and deliver these machines to our customers at prices 2 to 5 times cheaper than products in advanced industrial markets such as Europe, the US, and Japan," said engineer Son.

Fuji Machinery Manufacturing Co., Ltd. is also one of the few enterprises in Hai Duong province that participated in the largest trade exhibition in Vietnam dedicated to the manufacturing industry, FBC ASEAN 2023, held for 3 days on August 23, 24 and 25, 2023 in Hanoi. "Our booths attracted customers from Japan, China... and many domestic enterprises. They were all interested in our automated production lines and useful machines," added engineer Nguyen Hoang Lan.

Electricity bills account for a significant portion of manufacturing operating costs, with air conditioning sometimes consuming more than 50% of the total electricity consumption of many businesses. Realizing this, at the end of 2023, the new solution engineering team of Fuji Machinery Manufacturing Co., Ltd. collaborated with Viet International Technology and Trading Co., Ltd. (VG TECH) in Hai Duong City to deploy the Continewm panel application to save energy for air conditioners in industrial production. This product can reduce wasted electricity by “Eliminating performance degradation due to static electricity” of air conditioners.

Many businesses have signed contracts to install this product. The pioneer is Messer Vietnam Industrial Gas Co., Ltd. Since December 2023, this business has simultaneously deployed this application in many factories in Hai Phong, Hai Duong, Binh Duong... "Our business applies Continewm because through experiments, it has been shown that it can reduce up to 13% of the total electricity consumed by air conditioners in production areas. This contributes to the goal of green growth", shared engineer Nguyen Vuong, an officer of Messer Hai Phong Industrial Gas Co., Ltd. - Hai Duong Branch.

Trusted by partners

Established in January 2017, Fuji Machinery Manufacturing Co., Ltd. has maintained stable operations, the market continues to expand, the number of customers and orders has increased. In 2023, the company manufactured 33 production lines and 96 automated machines. In addition, it also provides installation, operation consulting and repair services. The company's annual revenue reached 30 billion VND, exceeding the plan by 15%.

In the first 2 months of 2024, the company has implemented 12 orders, mainly assembling and transferring automated production lines...

The company maintains dozens of regular customers such as Sumidenso Vietnam Co., Ltd., Hyundai Kefico Vietnam (Hai Duong); Hitachi Astemo Vietnam, Hamaden Vietnam (Hung Yen); KYB Manufacturing VietNam (Hanoi)...

In addition, the company is constantly conquering new customers. IKKA Vietnam Technology Co., Ltd. in Tan Truong Commune (Cam Giang), specializing in the production of auto and motorbike components, has just become a new customer with a product line that automatically checks products and monitors assembly parts. "After researching, we decided to cooperate with Fuji Machinery Manufacturing Co., Ltd., because this is a business that is always at the forefront of researching and applying new technology solutions, especially always accompanying customers with prestige, together overcoming difficulties," said engineer Nguyen Van Khai, Head of Technical Department of IKKA Vietnam Technology Co., Ltd.

JACKIE CHANSource

![[Photo] National Assembly Chairman Tran Thanh Man attends the Policy Forum on Science, Technology, Innovation and Digital Transformation](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/13/c0aec4d2b3ee45adb4c2a769796be1fd)

![[Photo] Prime Minister Pham Minh Chinh chairs the Government's special meeting on law-making in April](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/13/8b2071d47adc4c22ac3a9534d12ddc17)

![[Podcast]. Kites and Childhood](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/13/a4697c2294a843f39084a21134c3feb0)

Comment (0)