CPU or microprocessor acts as the brain of technological devices such as smartphones, computers, laptops... But few people know that behind the power of CPU is a product from a food company - Ajinomoto Group.

From amino acid technology to insulating and heat-insulating films

In the 1940s, the Ajinomoto Group began exploring applications for co-products in the production of umami seasoning from amino acids. Accordingly, some of these ingredients have excellent material properties and can be used as epoxy resin curing agents, non-stick paper, and coatings for the electronics industry.

As microprocessors become smaller and faster, printed circuit board manufacturers need better electrical and thermal insulation to maintain performance. Ink is the preferred substrate, but applying and drying it slows down manufacturing, attracts impurities, and creates byproducts that are harmful to the environment.

In 1996, a CPU manufacturer approached the Group about developing an insulating, heat-insulating film using amino acid production technology. That was a revolutionary moment.

Ajinomoto Build-up Film™.

The ABF development project was led by a promising young researcher, Shigeo Nakamura, whose background was in the study of insulating materials for electronic circuit boards. Initially, his team struggled to find a suitable material that was both durable and flexible.

Mr. Shigeo Nakamura (Chairman of Ajinomoto Fine-Techno Co., Inc., currently President and CEO of Ajinomoto Group), second from right, and his team.

“I was young and inexperienced at the time, so I chose a plastic that needed to be frozen,” Nakamura recalls. While his risky decision paid off, the next big challenge was finding a machine to press the new plastic film onto the base layer.

Spending weekends visiting the machine manufacturer to double-check the process, Mr. Nakamura finally figured it out. “ It’s like running a marathon, you just have to keep running, ” Mr. Nakamura said. In the end, the revolutionary new material, ABF, was perfected in just four months.

ABF has superior properties such as being the world's first film produced from liquid resin, an environmentally friendly production process, meeting the continuous development of CPU capabilities, and being able to meet customer requirements.

Market leader for over 2 decades

As an 'outsider', Ajinomoto initially faced challenges in gaining acceptance for its new product. Fortunately, there was a lot of upheaval in the CPU industry at the time, with the shift from ceramic to plastic cases. In 1999, a supplier to a leading semiconductor company introduced Mr. Nakamura to the largest CPU manufacturer.

He seized the opportunity, and ABF has been the market leader ever since. When the product was first introduced, Nakamura predicted it would only be in production for 10 years, but it has been over 20 years now and ABF is still going strong.

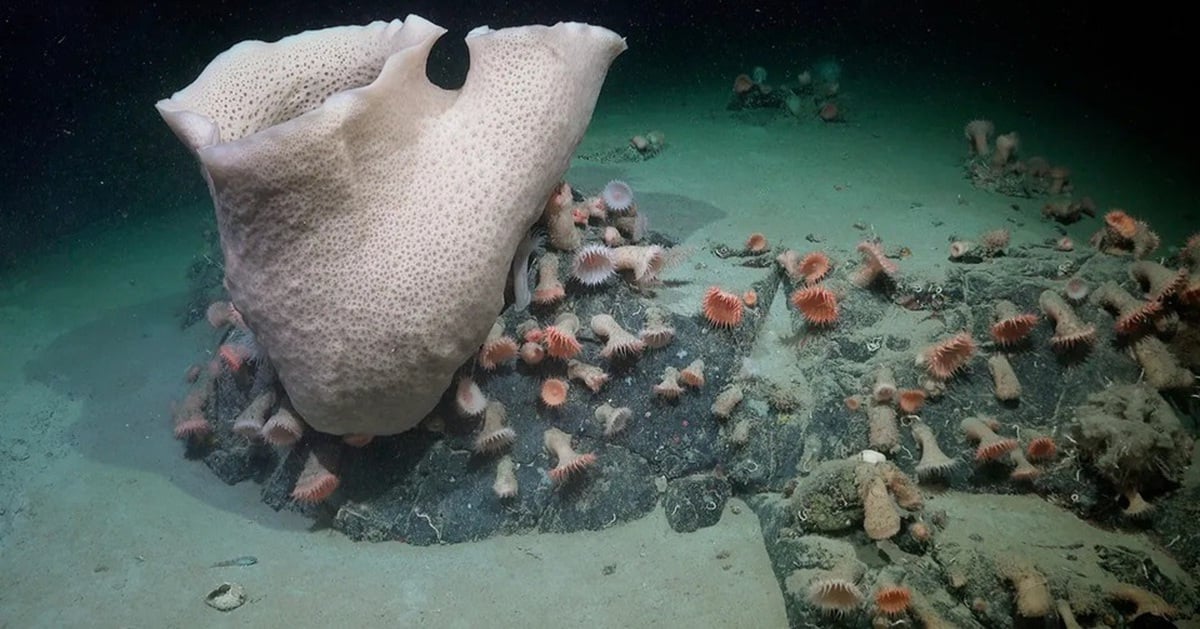

ABF is still going strong after more than 2 decades of launch.

In computers, mobile devices, 5G networks, self-driving cars, cloud services, IoT devices, or wherever advanced electronics are transforming our world, ABF remains a vital component. It is a prime example of the “pioneering spirit” – one of the four core values – the DNA of generations of Ajinomoto Group people, creating connections around the world.

The Ajinomoto Group is aiming to continuously develop different generations of semiconductor coating films with various materials such as molding materials, magnetic materials, photosensitive materials, and moving towards optical wave materials to meet the rapidly evolving requirements of the information and communication technology industry for a future society of high-speed communication, intelligence, and automation even in vehicles.

Source: https://vtcnews.vn/ajinomoto-build-up-film-dua-tap-doan-ajinomoto-tien-vao-linh-vuc-cong-nghe-ar933672.html

![[Photo] Prime Minister Pham Minh Chinh meets with the Ministry of Education and Training; Ministry of Health on the draft project to be submitted to the Politburo](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/25/c0e5c7348ced423db06166df08ffbe54)

![[Photo] Head of the Central Propaganda and Mass Mobilization Commission Nguyen Trong Nghia received the delegation of Nhan Dan Daily](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/25/cdb71275aa7542b082ec36b3819cfb5c)

![[Photo] Nhan Dan Newspaper Youth Union visits Vietnam Military History Museum](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/25/374e4f70a35146928ecd4a5293b25af0)

![[Photo] General Secretary To Lam chairs the Standing Meeting of the Central Steering Committee on preventing and combating corruption, waste and negativity](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/3/25/839ea9ed0cd8400a8ba1c1ce0728b2be)

Comment (0)