In recent years, with the focus on building and promoting the team of cadres and scientists of the Institute of Technology, the General Department of Defense Industry (GDDI) has researched and manufactured many weapons and technical equipment products to serve training and combat readiness for units, contributing to improving the proactiveness of the domestic defense industry, reducing dependence on imported weapons, supplies and components from abroad.

The “idea group, expert group” model

The initiative "Upgrading and digitizing measuring microscopes to serve the inspection of weapon parts requiring high precision" led by Lieutenant Colonel, Dr. Le Xuan Cam, Deputy Director of the Measurement Center (Institute of Technology) has been effectively applied in many factories under the General Department of Defense Industry and a number of units throughout the army.

Talking about the research process of this initiative, Lieutenant Colonel, Dr. Le Xuan Cam said that the measuring microscope is a measuring device based on the principle of non-contact measurement with high precision of µm, applied in many precision mechanical manufacturing units. However, this device is mainly donated by foreign countries, used for decades, so it has degraded (the optical system is blurred, the mechanical system is worn, dirty, stuck, the X, Y coordinate reading mechanism is incorrect...); the measurement results depend a lot on the person measuring; some dimensions are difficult to measure or cannot be performed (virtual center, diameter measurement, center distance measurement, complex contours...); the measurement results and measurement images are not saved for verification. In some units, the measuring microscope is equipped according to the new project, has high automation capability, but after a period of use, the optical scale, camera, measurement software have errors, large errors...

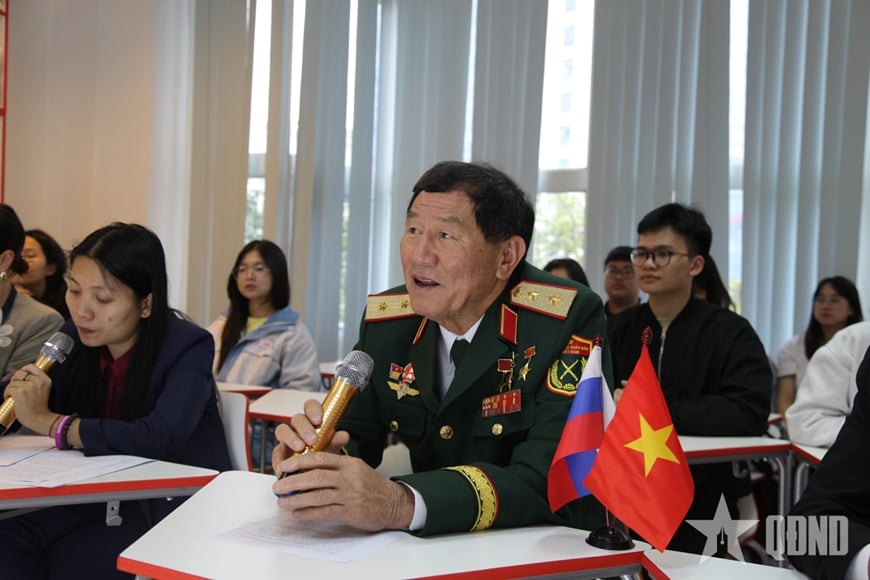

|

Officers and engineers of the Institute of Technology (General Department of Defense Industry) discuss scientific products. |

“Given the above situation, we proposed the idea of upgrading and digitizing measuring microscopes to serve the inspection of weapon parts that require high precision. After the Center's commander gave his opinion, the initiative group asked the Institute's expert team to advise on techniques, technology, materials, coordination, testing, etc. The highlight of the initiative is the use of new measuring sensors to digitize the X, Y axis displacement system; read measured values directly with an electronic display. Measured data and images are stored on the computer. The initiative can be applied to all precision mechanical manufacturing facilities inside and outside the Army,” said Dr. Le Xuan Cam.

According to Colonel Le Anh Tuan, Political Commissar of the Institute of Technology, the model of "Idea Group, Expert Group" initially operated spontaneously, but through practice it brought practical results, so the Institute's commander organized the activities systematically, creating an environment for staff and employees to conduct scientific research. This model has promoted the intelligence of scientists, especially the team of young scientists, in proactively seeking new and creative things in the field of technology. With the advice of experts, almost all topics and initiatives are implemented close to the requirements and tasks.

Proactively create human resources

The work of planning, creating resources, and training a team of cadres doing scientific work has always received special attention from the Party Committee of the Institute of Technology. Major Dang Xuan Dung, Research Assistant, Missile Technology Department, is a young cadre with many achievements in scientific research, with many topics and initiatives effectively applied in practice, and has won the Creative Youth Award in the Army. In order to produce quality scientific products, in addition to being trained abroad, Dang Xuan Dung was sent by the Institute's commander to factories to experience reality, learn experience and knowledge from practice.

According to Colonel Le Anh Tuan, selecting young cadres to be sent to factories not only trains their mettle and improves their professional qualifications, but also serves as a basis for the Institute to assess each individual’s capacity, especially their scientific research ability; thereby orienting training, fostering, and arranging and using cadres. In addition, many young cadres are assigned to preside over scientific research topics at the Ministry of National Defense and General Department levels; participating in the implementation of key projects of the above will gradually improve their qualifications, knowledge and working skills.

With scientific solutions in training, fostering, planning and using human resources, up to now, 100% of the Institute's staff have a university degree or higher, of which more than 72% have a postgraduate degree (19.5% have a doctorate). The number and quality of scientific staff have been improved, promoting strong research groups in a number of fields, meeting the requirements and assigned tasks. Currently, the Institute of Technology's staff and engineers have initially researched, manufactured and mastered the technology of parts of high-tech weapons, mobile weapons, and system integration, such as: low-altitude air defense missiles, combat and reconnaissance robots, infantry fighting vehicles, self-propelled artillery; basically mastered the design and manufacturing technology of most types of army ammunition, anti-aircraft ammunition and some types of naval ammunition, manufacturing artillery shells, gun barrels, anti-submarine bomb launchers, some special alloy grades...

Article and photos: SON BINH

*Please visit the National Defense and Security section to see related news and articles.

Source

Comment (0)