Associate Professor, Dr. Huynh Trong Phuoc (Can Tho University) participated in the research of concrete-like materials from sewage sludge and fly ash applied to leveling.

Associate Professor Huynh Trong Phuoc (35 years old) has just been awarded the 2023 Golden Globe Award for his outstanding achievements in the field of scientific research and training, of which creating materials from waste sludge is one of the outstanding projects.

Associate Professor Phuoc said that the research was conducted when he was doing his PhD at the National Taiwan University of Science and Technology 7 years ago. At that time, a wastewater treatment company in Taipei ordered a study to use the available sludge at the factory as material for internal landfill within the campus.

Dr. Phuoc and his research team have developed a formula for mixing sediment with fly ash and a small amount of cement and other additives to create a controlled low-strength material (CLSM). The added cement and additives will create a favorable environment for fly ash and sediment to participate in chemical reactions, forming a CLSM material with load-bearing capacity.

Associate Professor Dr. Huynh Trong Phuoc (2nd from left) during his time studying and researching in Taiwan. Photo: NVCC

He said that the sludge in wastewater treatment plants contains a fairly high content of silicon dioxide (SiO2) and aluminum oxide (Al2O3), which is similar to the composition of fly ash in coal-fired thermal power plants. The density and particle composition of these two materials are not much different, so they are very suitable for mixing to make CLSM materials. "Depending on the specific needs of the ordering unit, the content of each material component can be adjusted to obtain a product that meets the requirements for use," he said.

The research team has developed a process to create CLSM materials using sludge and ash taken directly from emission sources to the laboratory and used directly without further processing.

Associate Professor Phuoc said that depending on specific conditions, it is possible to mix directly with moisture or mix dry (the material must be dried before use). For CLSM materials for landfill, the group chose the wet mix method to save on processing costs.

Sludge collection stage at the factory for research purposes. Photo: NVCC

After many tests in the laboratory, evaluating and adjusting the steps, the team optimized the formula so that the product met the requirements for use. This was also the most difficult and time-consuming step, requiring design calculations and mixing. The team had to try many times because each time a small amount of ingredients was adjusted, the properties of the product would change significantly. In addition, the mixing method and process, and the type of equipment used also greatly affected the research results.

Compared with traditional sand filling materials, Associate Professor Phuoc said that these are two completely different methods. When filling with conventional sand, it relies on the energy of the roller to compact the material to a design density for acceptance. Meanwhile, CLSM is a controlled low-strength material, like a type of concrete designed with properties to serve different purposes, which means it can be completely adjusted according to usage requirements. The higher the quality requirements, the corresponding increase in production costs.

The material has great potential in practical applications for landfill, however, Associate Professor Phuoc said that in order to be able to put it into mass use as a common landfill material, it is necessary to analyze the actual production costs and assess the long-term environmental impact. "There needs to be specific standards and regulations on technical requirements for construction and separate acceptance," he said. In addition, the source of sludge and fly ash materials needs to have a stable collection source in terms of quality, providing enough large reserves for industrial production scale to have a basis for practical application.

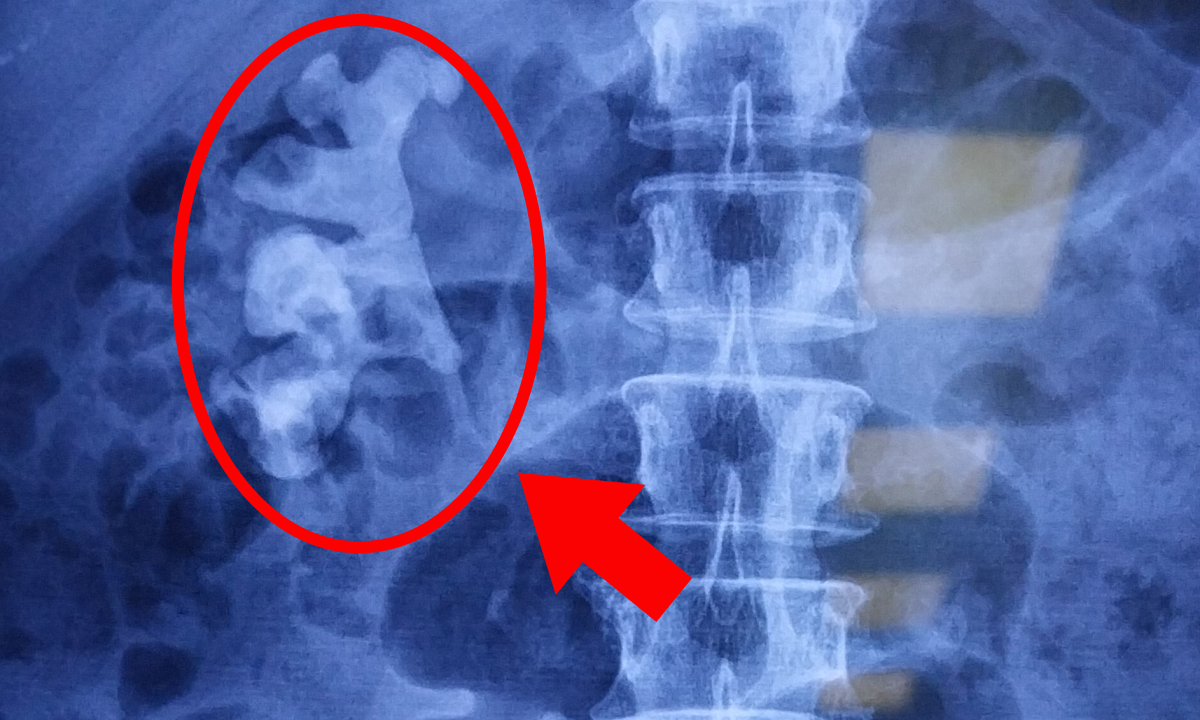

CLSM material microscope image of the research team. Photo: NVCC

The team’s research was highly appreciated and a trial landfill was deployed in the premises of a water treatment plant in Taipei. Preliminary assessments immediately after deployment demonstrated the high applicability of the designed material. The team is monitoring and sampling periodically to monitor the long-term performance of this material to serve the optimization of design methods and construction methods for CLSM materials.

There have been some studies in the country on the application of fly ash and sludge as a filling material, but not many have been published in scientific papers. To apply in Vietnam, it is necessary to develop a set of technical standards as a basis for calculating material norms, to be used in bridge and road projects using state budget capital.

In addition, the source of raw materials must ensure stability and continuity to carry out large-scale projects. Fly ash can meet the demand, but according to Associate Professor Phuoc, it is difficult to satisfy the demand for sludge because water treatment systems only dredge once every 1-2 years. He said that this problem can be solved by researching the use of other resources to replace sludge or changing the formula to increase or decrease the proportion of raw materials but still meet the requirements. "Currently, there are traffic construction companies that have proposed a small-scale pilot project, then proposed to establish technical standards, environmental impact assessments and other procedures for mass implementation," said Associate Professor Phuoc.

vnexpress.net

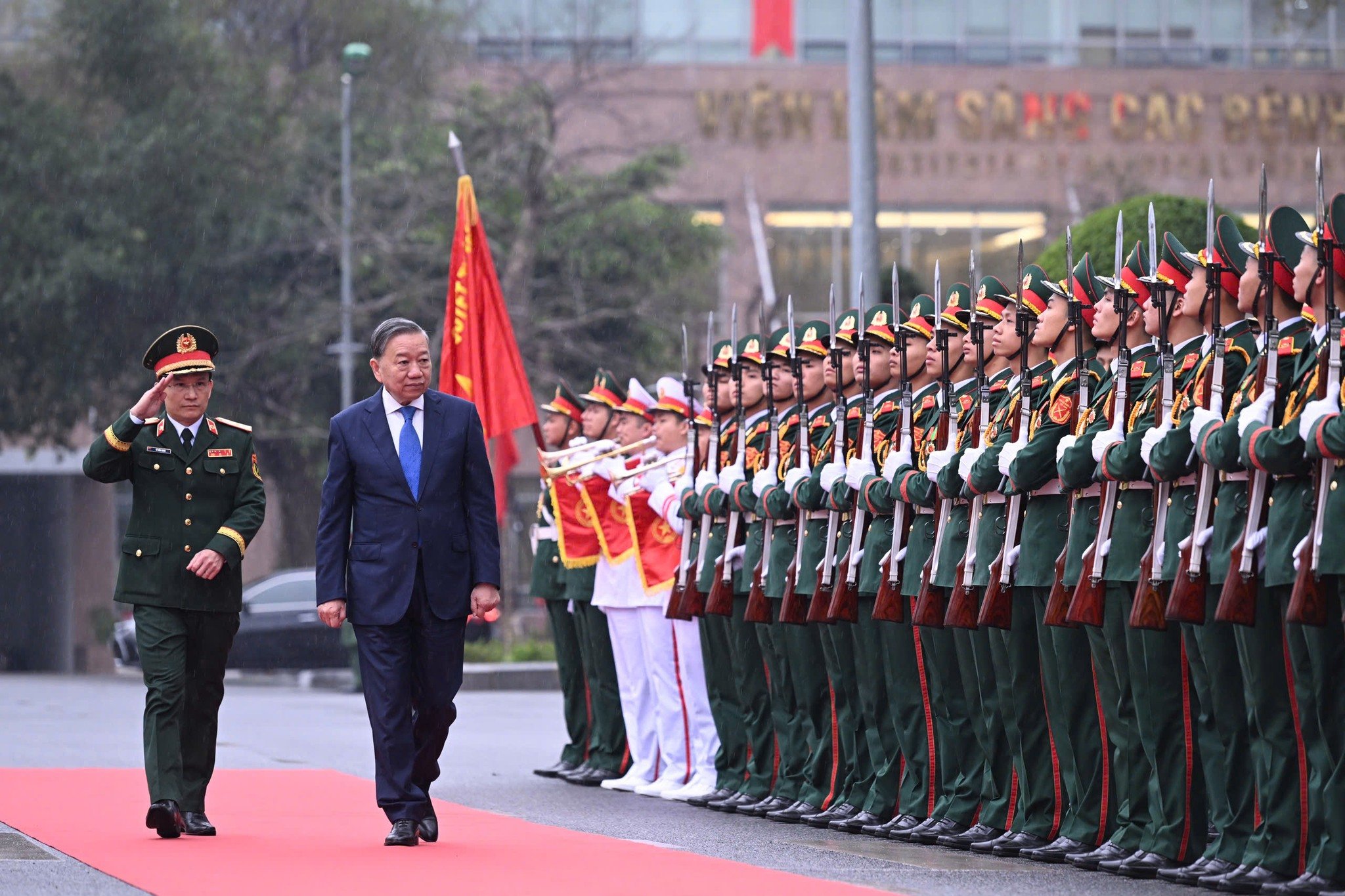

![[Photo] Prime Minister Pham Minh Chinh chairs Government Conference with localities on economic growth](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/2/21/f34583484f2643a2a2b72168a0d64baa)

Comment (0)