Tran Thi Quynh's solution of using snake plant leaves to create silk fibers for wigs is expected to help people have more income and won the prize at the 2023 Science Initiative Competition.

Tran Thi Quynh (18 years old), Muong Nhe High School, Muong Nhe District, Dien Bien Province shared that the idea came to her when she and her teacher Nguyen Thi Cam Nhung watched a program about cancer patients undergoing chemotherapy, losing their hair but not being able to afford to buy wigs. Quynh said that wigs made from real hair are very expensive, and those made from synthetic fibers will affect the environment during the production process. "I thought why not make wigs from natural materials, both reducing costs and not polluting the environment," Quynh said.

Under the guidance of Ms. Cam Nhung, Quynh researched and learned about natural fibers from cotton, silk, linen, and hemp, but they could not be used to make wigs because they were easily shrunk and frizzy. In the process of searching for new sources of raw materials, the teacher and student noticed the snake plant because of its advantages such as strong, white fibers that were easy to dye, had high durability, and did not frizz. After surveying and seeing that the plant grew wild in all the villages, they decided to experiment with the leaves of the snake plant to make handmade silk fibers without using chemicals.

To do this, the group harvested the leaves of the snake plant, washed them, used a pestle to crush the leaf flesh, then incubated them with Emuniv probiotics for about 7-10 days. The snake plant leaves will decompose after being soaked, then the silk fibers are separated. "The silk fibers are essentially tubular and filamentous in the leaves, so it is necessary to remove the cutin layer on both sides of the leaves to make it easier to remove the leaf flesh from the silk fibers," Quynh said, adding that young and old snake plant leaves produce stronger silk fibers and are less likely to break during the separation process.

During the production process, the team added some nourishing products such as aloe vera leaf extract; enzyme solution from pineapple, orange, lemon peel to make the thin silk fibers tough and soft. After soaking for about 6 hours, the silk was dried. The resulting silk fibers were quite soft, stored at room temperature for 8 weeks without mold. The finished wigs were still in good condition after 2 years of use by students in the school.

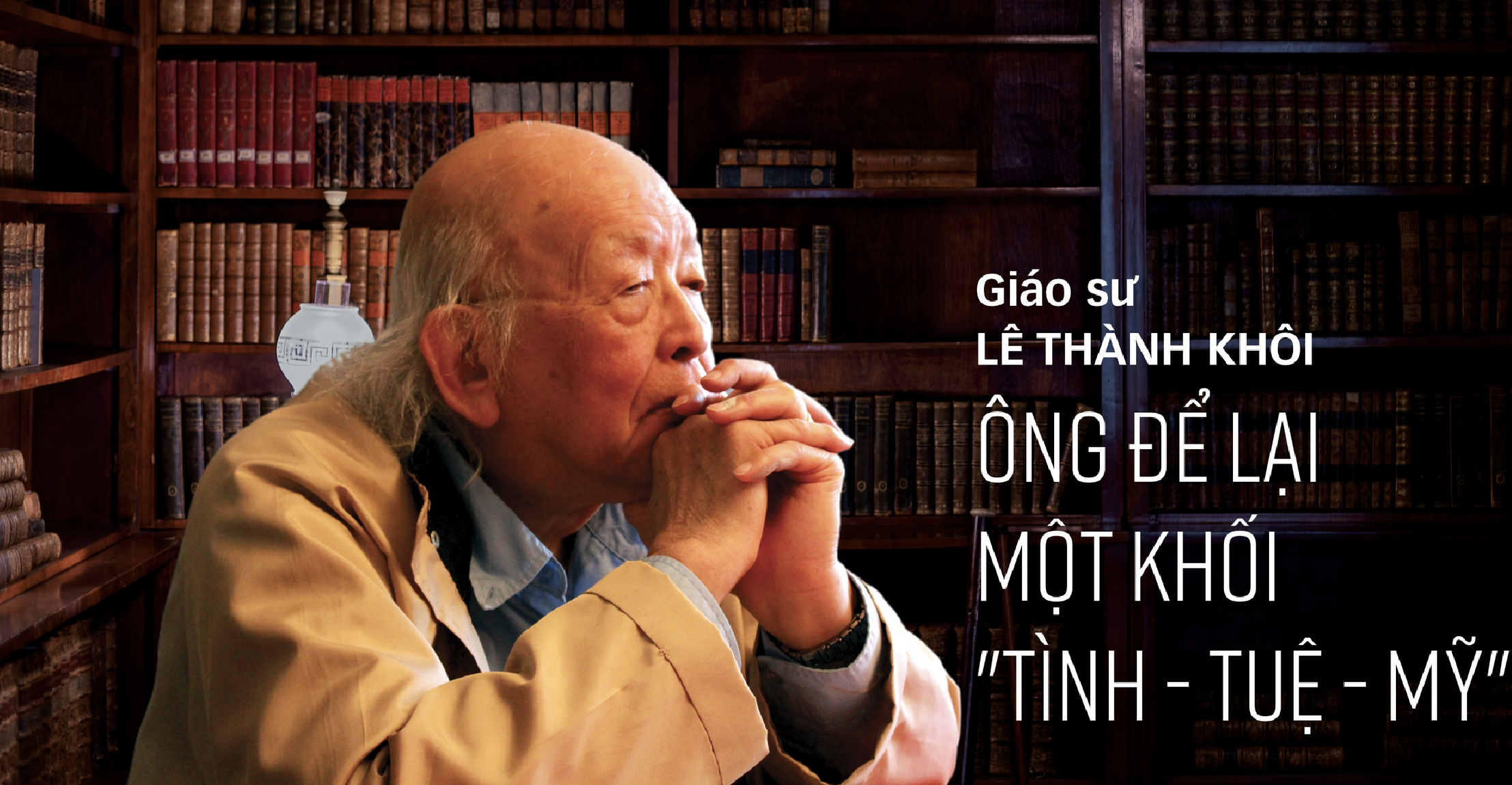

Wigs made from snake plant leaves by students in Dien Bien. Photo: NVCC

The group also used natural ingredients such as turmeric, ripe Malabar spinach, and coffee powder to dye the silk fibers, then shape them into wigs. To test the product's heat resistance, the group used a hair straightener and curler at the temperature normally used on real hair. "The results showed that wigs made from snake plant silk fibers have good heat resistance and can easily change their style," Quynh said.

Sharing with VnExpress , teacher Nguyen Thi Cam Nhung, Head of the Professional Group and Vice President of the Trade Union of Muong Nhe High School, said that the most successful point of the project is taking advantage of available natural and safe raw materials during use. "Although the research is still in its early stages, I have high hopes for the potential of product development, thereby helping people have new crops that bring economic efficiency and income," said Ms. Nhung.

Wigs and highlighted hair are very popular with students in the school. Ms. Nhung revealed that some students have really enjoyed separating the silk fibers and creating similar products, selling them online for only about 8,000 to 10,000 VND/wig or using them as gifts. In addition to making wigs, silk fibers are used to make makeup brushes, braid into ropes, weave baskets, nets, hammocks, make foot mats, dusters, weave bracelets and some handmade items.

In the near future, the group will continue to perfect the wig product with a smoother shine, weave the silk fibers into fabric pieces and create packaging products, fashion handicrafts. In addition, the group also came up with the idea of making a machine to press the leaves of the snake plant to get silk to shorten the time and effort.

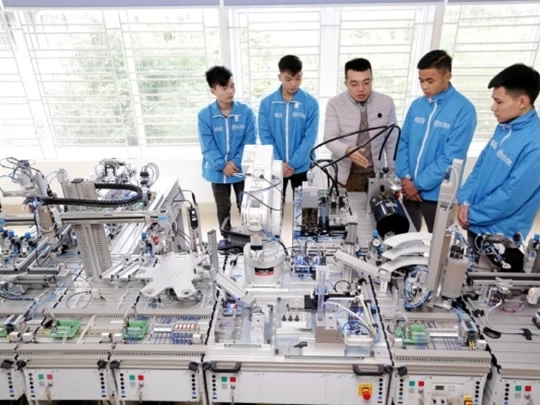

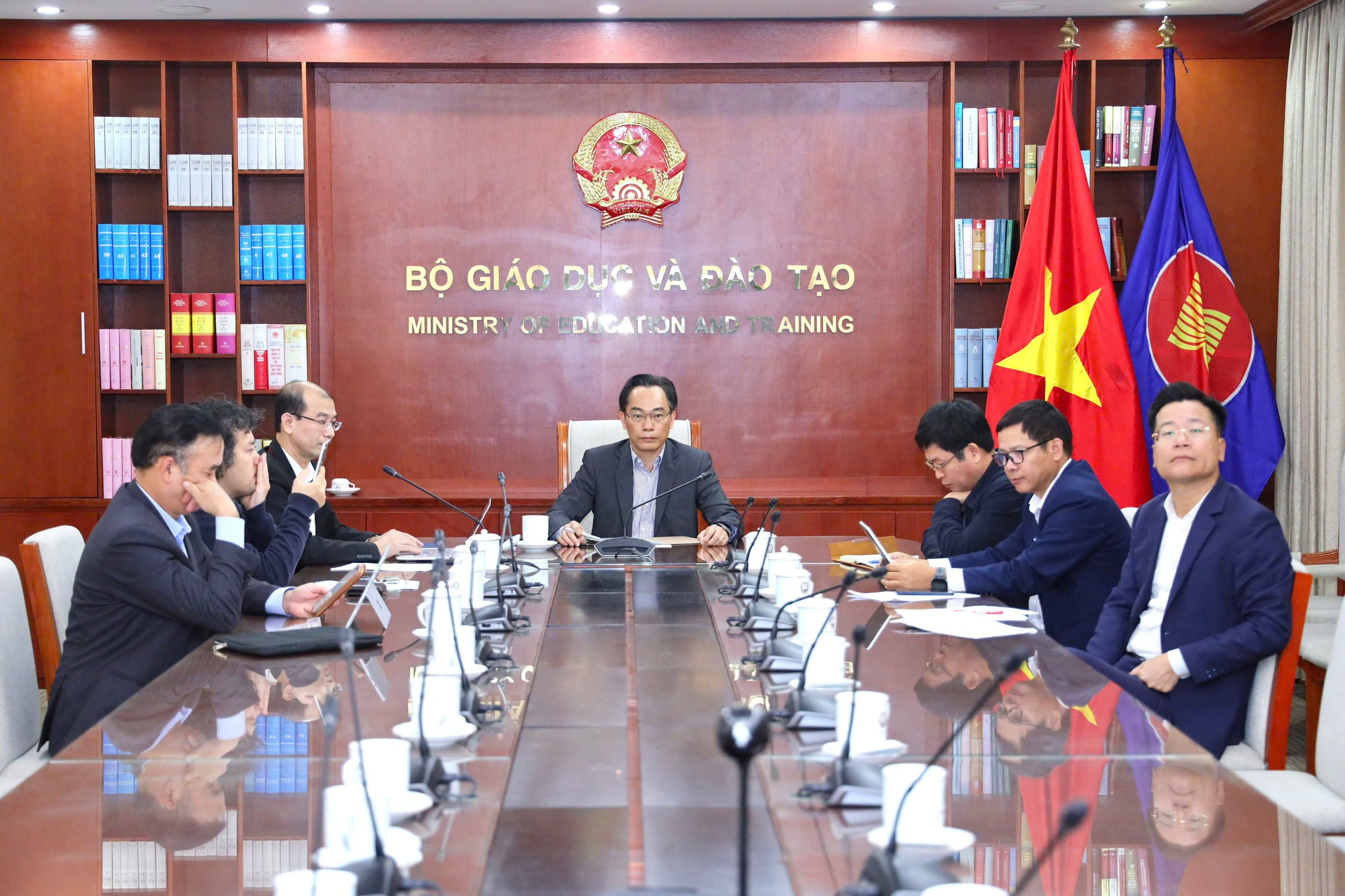

Student Tran Thi Quynh (middle) and teacher Nguyen Thi Cam Nhung received the innovation award. Photo: Giang Huy

The project received the "Innovation Award" at the 2023 Science Innovation Competition, and was assessed by the Jury as having a good idea and full of humanistic meaning. Although the technology is not very new, the initiative is especially oriented towards regional support, serving people in remote and isolated areas.

In its second year, VnExpress's 2023 Science Initiative Contest hopes to create a playground for those who love science and technology; targeting professional and non-professional scientists under 40 years old, to seek initiatives, solutions, and connections to accelerate the application of advances in science and technology. The "Initiative Award" to serve people in remote, mountainous areas worth 30 million VND is also a new category this year.

Nhu Quynh

Source link

![[Photo] Prime Minister Pham Minh Chinh chairs Government Conference with localities on economic growth](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/2/21/f34583484f2643a2a2b72168a0d64baa)

Comment (0)