Dong Thap A group of young people have successfully produced paper from lotus stems, used in fine arts, gift bags, decorative labels, helping to protect the environment.

Ms. Nguyen Thi Thuy Phuong, 42 years old, head of the research team, said that she had worked in the Northwest for 8 years and experienced how the Mong and Dao people make paper from plants.

When she arrived in Dong Thap, she saw that the source of by-products from lotus stems was huge but farmers cut them down or buried them in the ground, so she came up with the idea of making paper. In the middle of this year, the group started researching, experimenting many times and found the process of producing paper from lotus stems.

Lotus stems - an agricultural by-product with large reserves but not yet utilized, often cut down or buried in the ground. Photo: Ngoc Tai

According to the traditional paper making method, lotus stems are boiled in lime water for 6-8 hours. The craftsman will then separate the fibers (cellulose) from the lotus stems, clean them, and soak them with microorganisms for about a week, helping the fibers to naturally whiten and remove the remaining residue.

The fibers are pounded with a stone mortar and mixed with water to create a fiber powder mixture. The mixture is put on a frame and evenly spread using a hydraulic nozzle. Compared to manual spreading, the nozzle helps the paper to be flatter and more even. The paper is dried for about two hours before it can be used.

According to the research team, lotus stems contain about 30% cellulose, just lower than lotus mirrors, but the plant fibers from the stems can self-bond together. Lotus paper has the advantage of being flexible, not tearing when crumpled, absorbent, and has a natural smell... Bags and packaging made from lotus stems can use plant-based adhesives to increase their strength.

On average, 10 kg of lotus stems yield 0.6 kg of fiber pulp mixture, which can make one meter of paper. Lotus stems are quite cheap, but the steps require a lot of labor, making the cost of lotus paper about 110,000 VND per square meter. According to the research team, most of the steps can be replaced by machines to increase productivity and reduce costs. The team is currently ordering fiber pounding machines.

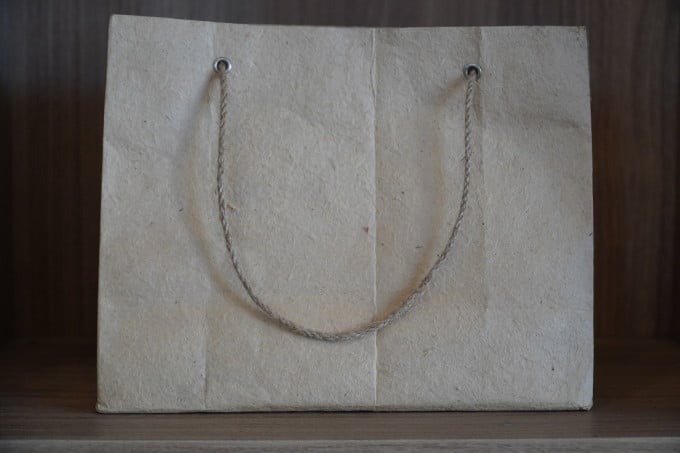

Lotus paper after drying. Photo: Ngoc Tai

In the near future, young people will deploy a pilot model before transferring the production process to lotus growers, making finished products or fiber pulp to sell to paper manufacturing enterprises. A lotus souvenir business has put lotus paper bags into business since November.

According to Ms. Phuong, while there is no industrial scale production, people can take advantage of their free time to earn extra income. In addition, through trade promotion opportunities, the group introduces lotus paper to businesses specializing in packaging processing, fine arts and gift units, looking for long-term output...

The group is nurturing and implementing the experience of making lotus paper for tourists coming to Dong Thap, both developing tourism and creating output for lotus products. The young people hope that lotus paper will contribute to perfecting the value system of the lotus industry in Dong Thap province in green transformation and circular economy.

In addition to lotus paper, many young entrepreneurs in Dong Thap have successfully commercialized lotus products such as lotus tea (from lotus leaves and hearts), bottled soft drinks, processed foods made from lotus seeds and lotus roots, lotus leaf bags, souvenirs, perfumes, essential oils, etc.

Souvenir paper bags made from lotus stems. Photo: Ngoc Tai

Mr. Le Quoc Dien, Deputy Director of the Department of Agriculture and Rural Development of Dong Thap province, said that lotus paper is a circular product in the lotus value chain. Currently, no part of the lotus is discarded, from leaves, stems, seeds, and roots.

"Farmers have more income, helping them to be more attached to this agricultural product," he said. Dong Thap has more than 1,200 hectares of lotus, with a yield of 900 kg of lotus seeds per hectare, and 49 lotus products that have achieved OCOP certification (one product per commune according to the standards of the Ministry of Industry and Trade).

Ngoc Tai

Source link

![[Photo] Vietnamese rescue team shares the loss with people in Myanmar earthquake area](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/6/ae4b9ffa12e14861b77db38293ba1c1d)

![[Photo] Solemn Hung King's Death Anniversary in France](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/6/786a6458bc274de5abe24c2ea3587979)

![[Photo] Military doctors in the epicenter of Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/6/fccc76d89b12455c86e813ae7564a0af)

![[Photo] Prime Minister Pham Minh Chinh chairs the regular Government meeting in March](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/6/8393ea0517b54f6791237802fe46343b)

Comment (0)