On April 1, 2020, the People's Committee of Phu Tho province issued Plan No. 1328/KH-UBND to implement the National Program on economical and efficient use of energy for the period 2020 - 2030 in Phu Tho province. The purpose of the Plan is to effectively organize the implementation of the Law on Economical and Efficient Use of Energy and related normative documents on energy use and consumption in the area; mobilize all resources to promote economical and efficient use of energy.

Thereby forming the habit of using energy economically and efficiently in all social activities. Implementing and deploying according to the Plan, in recent years the province has achieved positive results, contributing to the goal of striving to achieve an energy saving level of 3.0 - 5.0% of the total energy consumption of the whole province compared to the current forecast.

Part I: Reduce costs, increase efficiency

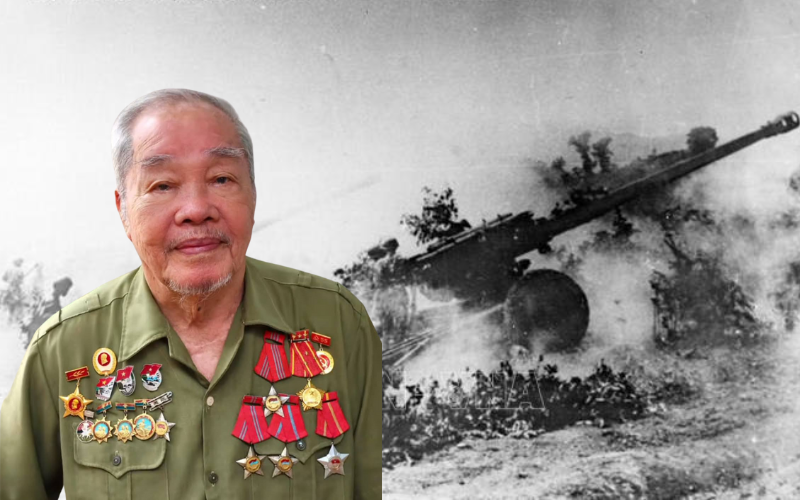

NPK-S fertilizer production line of Lam Thao Super Phosphate and Chemical Joint Stock Company.

Phu Tho is one of the localities with a fairly strong industrial development compared to the provinces in the North. This is a field that consumes a lot of energy, mainly electricity, coal and gasoline. Along with industrial production, in recent years, many infrastructure construction projects have been invested in on a large scale in the province. The number of high-rise buildings has increased, hospitals, offices, schools... have been invested in repairing and building new ones in a modern direction. In urban areas, towns, and cities, public lighting systems are increasingly installed on national highways, provincial roads, and district roads, leading to an increase in the main energy source in this field, electricity. Therefore, saving energy in the industry is an urgent requirement.

Promote innovation and technical improvement

As one of the major fertilizer producers, Lam Thao Super Phosphate and Chemical Joint Stock Company is always at the forefront of movements to promote initiatives and technical improvements. Up to now, hundreds of initiatives have been applied to production, bringing the Company tens of billions of VND in benefits. Among them, many initiatives aim to save energy in production.

In 2023, the topic "Research and implementation of equipment installation and renovation to improve the pelletizing efficiency of NPK 1 production line from 67% to 75%, contributing to increasing production line productivity and product granule form, saving electricity costs, labor and product drying heat" won the Third Prize of the Provincial Technical Innovation Competition.

Based on the reality at the Company, NPK 1 production line is producing NPK products that are granulated by pelletizing discs, using circulating water from the exhaust gas treatment absorption tank, supplemented with the Company's common water network. However, the low pelletizing efficiency leads to an increase in energy consumption per ton of product due to the drying, cooling, screening and recirculating crushing processes, and dust generation that affects the environment. The product granules are not round, many are deformed, and the particle size is uneven.

Comrade Trieu Dang Dinh - Deputy Head of Technical Department said: "After the process of research, survey and assessment, the initiative group proposed to renovate and supplement the equipment to improve the efficiency of pelletizing and granulating at NPK Line 1. With improvements in technology as well as machinery and equipment, after investing in the equipment system and stable operation, the efficiency of NPK pelletizing and granulating has been improved from 67% to 75% with a grain range of 2÷4mm. Significantly reducing the phenomenon of bottom adhesion of the disc, which is the cause of large lumps that reduce the productivity of the line. Contributing to improving the productivity of the line, improving the form of NPK product granules, reducing the consumption of raw materials, fuel, and dust emission".

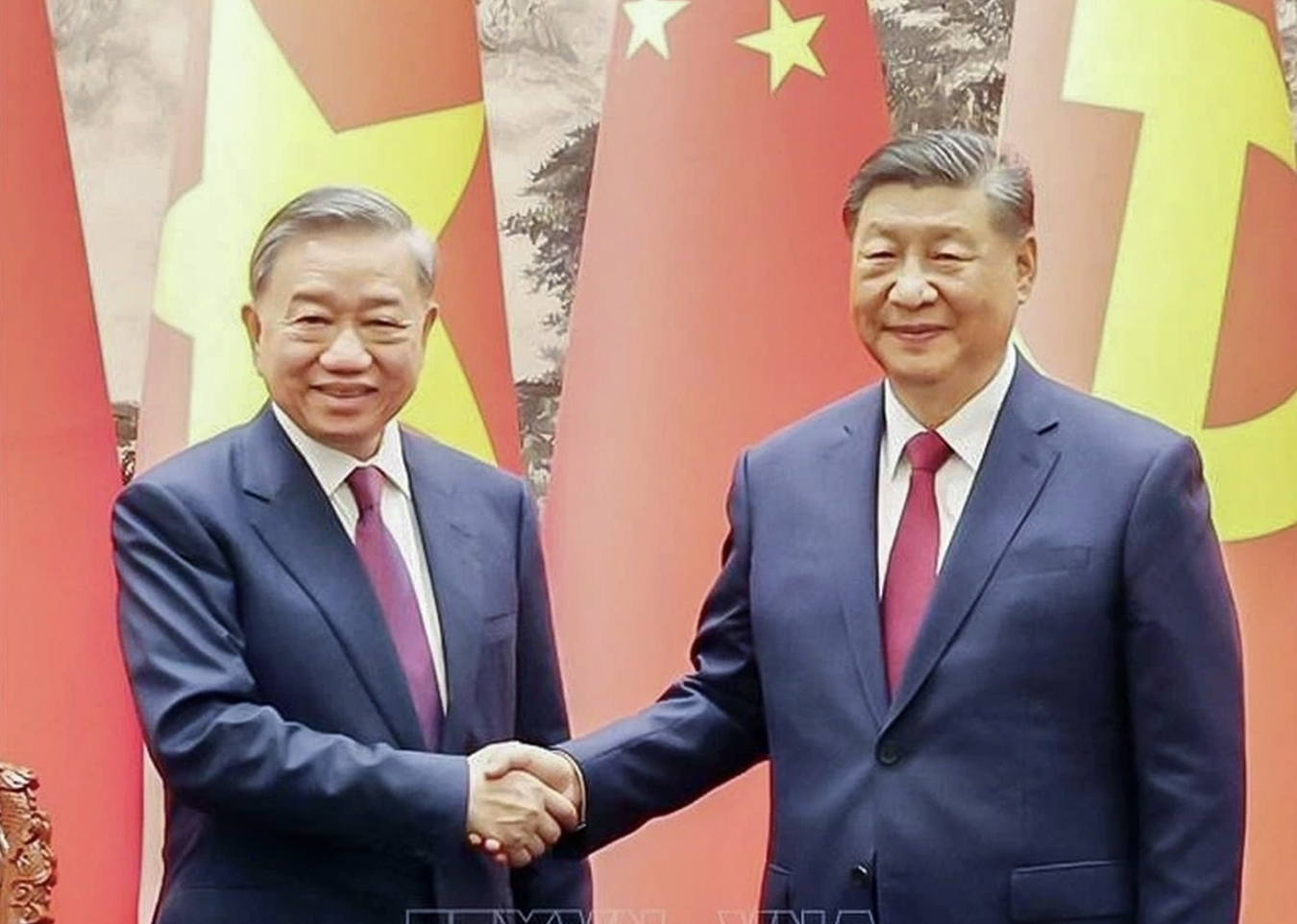

Following the Government's guidelines, Vietnam Cement Corporation (VICEM) has developed a program to use waste generated from social life and industries (such as industrial solid waste, hazardous waste, plastic waste, domestic waste, sludge from dredging rivers and lakes, ash and slag from thermal power plants, metallurgical slag, etc.) as raw materials and fuels to replace the use of non-renewable natural resources such as coal, limestone, clay, etc.

Following the direction of Vietnam Cement Corporation, VICEM Song Thao Cement Joint Stock Company promotes scientific research, improves technical initiatives and applies the results to production. In which, the project "Research on the use of waste coal as fuel for clinker smelting" of the Company has surpassed many projects to win the second prize of the Provincial Technical Innovation Contest in 2023.

VICEM Song Thao Cement Joint Stock Company applies scientific topics to production to bring high economic efficiency and protect the environment.

For the cement industry, coal is an indispensable fuel. However, in the context of the world in general and Vietnam in particular, this fuel source is increasingly depleted, the world coal market has many strong fluctuations, difficulties and risks. Faced with the difficulties of the scarcity of coal fuel and the increasing cost, affecting production efficiency, the study of the recovery of coal waste in the grinding process will be a problem that both brings economic efficiency and contributes to environmental protection. Therefore, in early 2021, the topic "Research on the use of coal waste as fuel for clinker smelting" was researched and applied by the group of authors of VICEM Song Thao Cement Joint Stock Company.

Comrade Nguyen Ngoc Xuan - Head of the Laboratory said: "When using waste coal, the remaining heat energy in the waste coal is returned to the Clinker smelting process, thereby reducing the heat energy put into the Clinker smelting process. On the other hand, the proportion of raw materials used for the mixing process is reduced; the quality of Clinker ensures technical requirements. From the success of this solution, currently, VICEM Song Thao Cement Joint Stock Company is researching the use of low calorific value coal to replace part of the coal in the clinker smelting process to bring high economic efficiency".

Practical, effective

In the context of increasing energy demand for production and daily life, continuous high growth in electricity load, gradually depleting coal, oil and gas resources, and heavy dependence on imports... using energy economically and efficiently is a practical solution, contributing significantly to ensuring energy security and economic development associated with green production. In that journey, many businesses have been actively practicing electricity saving and using clean energy in production.

Solutions for efficient energy use implemented by enterprises include: Arranging scientific production processes to reduce power loss; improving technical machinery, enhancing operating efficiency; applying technological improvement measures, rationalizing fuel combustion, heating, cooling and heat energy conversion processes; reducing heat and power loss during transmission, distribution and consumption of electricity; recovering energy from waste cycles for reuse...

Comrade Nguyen Ngoc Linh - Deputy General Director of VICEM Song Thao Cement Joint Stock Company said: When applying the topic "Research on using waste coal as fuel for clinker smelting", we have fully recovered the waste coal in the coal grinding process to avoid waste, diversify fuel sources to help ensure energy security in the context of scarce coal supply and continuously increasing coal prices. In terms of economic efficiency, since the application, the company has saved over 1 billion VND per year".

Currently, in Phu Tho province, some factories have invested in using new energy sources, renewable energy such as solar energy, bioenergy. Especially in rural areas, many families have built energy-saving biogas tanks and installed solar water heaters.

In industry, some agricultural processing industries such as tea processing from manual kilns; construction materials manufacturing industry also uses some energy sources from waste rubber, plastic, PE, PP... (such as CTH Joint Stock Company, Viet Tri Paper Joint Stock Company...) or uses forestry products such as firewood, sawdust to replace coal and oil.

Developing renewable energy sources, the province is implementing the construction of a waste treatment plant combined with power generation with a total capacity of 18MW, developing over 200 rooftop solar power systems with a capacity of over 3,100kWp.

Currently, the province's functional sectors have been actively supporting enterprises in applying, transferring, mastering, and developing technologies on energy saving and efficiency; integrating the field of energy saving and efficiency into scientific research and technology development programs; consulting and supporting enterprises with electricity and energy saving solutions; building energy management models, and supporting energy audits.

Recently, the workshop on propagating energy saving and efficiency for large energy-consuming industrial enterprises organized by the Center for Industrial Promotion and Industry and Trade Development Consulting, the Department of Industry and Trade in coordination with Phu Tho Electricity Company has disseminated and raised awareness for enterprises to effectively implement the policy on energy saving and efficiency. From there, it helps enterprises to effectively implement plans for energy saving, apply standards, technical regulations, and energy audits.

Delegates attending the Workshop were informed and disseminated the main contents of the Law on Economical and Efficient Use of Energy; at the same time, they were introduced to solutions for using renewable energy and environmentally friendly solar energy. Along with improving corporate governance, economical and efficient use of energy is an important solution, helping to reduce production costs and increase competitive advantages. This is also a solution to create conditions for businesses to move towards the goal of green and sustainable production.

Part II: Requirements from practice

Thu Ha

Source: https://baophutho.vn/tiet-kiem-nang-luong-huong-den-nen-kinh-te-xanh-219749.htm

![[Photo] "Beauties" participate in the parade rehearsal at Bien Hoa airport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/155502af3384431e918de0e2e585d13a)

![[Photo] Looking back at the impressive moments of the Vietnamese rescue team in Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/5623ca902a934e19b604c718265249d0)

![[Photo] Summary of parade practice in preparation for the April 30th celebration](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/78cfee0f2cc045b387ff1a4362b5950f)

Comment (0)