Vietnam has high recycling capacity.

The Law on Environmental Protection (LEP) 2020 has fully and clearly institutionalized the Extended Producer Responsibility (EPR) mechanism for the collection and recycling of products and packaging with recyclable value (Article 54). The collection and recycling of products and packaging (including plastic packaging) under the EPR mechanism is considered a necessary and urgent content to effectively manage plastic waste streams in Vietnam.

According to the IUCN report (2020), in 2018, Vietnam recycled 924,000 tons of plastic, of which domestic plastic scrap accounted for only about 1/3. Research by the World Bank (2021) showed that in 2019, 1.28 million tons (33%) of plastic scrap were recycled out of a total of 3.9 million tons of PET, LDPE, HDPE and PP plastic consumed in Vietnam (not to mention a large proportion of imported plastic scrap). This means a loss of 75% of the material value of the total amount of plastic waste, equivalent to 2.2 - 2.9 billion USD per year.

Meanwhile, international organizations assess that Vietnam's total plastic recycling capacity is very large. As of June 2022, there were 76 enterprises licensed to import plastic scrap as raw materials for production (mainly PE, PET, PS, PVC and PP). The General Department of Environment (GDEA) has compiled information from the General Department of Customs and scrap import reports of provinces and cities. The results show that the volume of imported plastic scrap in 2019 was 2,313,600 tons; in 2020 it was 468,300 tons and in 2021 it was 742,800 tons (the volume of imported plastic scrap decreased sharply in 2020 and tends to increase again in 2021 due to restrictions caused by the COVID-19 pandemic).

The total amount of plastic scrap licensed for import by 76 licensed enterprises is over 3 million tons/year; adding up to 20% of domestic plastic scrap will increase the total scrap recycling capacity of regular scrap importing facilities to about 3.5 million tons, not to mention other manufacturing facilities using domestic plastic scrap with a capacity of about 1 million tons. This shows that the recycling capacity of the regular sector is very large. However, the current reality shows that the regular recycling sector only focuses on receiving a number of clean and easy-to-collect domestic plastic scrap streams, usually from common industrial solid waste sources or plastic scrap sources collected at households, provided through agents or scrap companies.

Particularly in craft villages that specialize in using domestic scrap, incomplete statistics show that the total recycling capacity in this area is estimated at about 2 - 2.2 million tons. The source of plastic scrap comes from domestic solid waste. This is also the reason why a large amount of plastic packaging products are currently not managed and recycled properly; not meeting the requirements for high-quality products. Even when plastic recycling enterprises have a waste sorting and cleaning line, and can receive domestic plastic scrap, they often cannot compete with informal manufacturers because the scrap purchase price is too high compared to the production cost.

Determine recycling costs based on efficiency

In order to support the Ministry of Natural Resources and Environment in effectively implementing the EPR mechanism in Vietnam, from 2022 to April 2023, through the Project "Reducing Ocean Plastic Waste in Vietnam", WWF Vietnam has chaired the research and development of Fs cost norms for plastic packaging products according to the provisions of Decree No. 08/2022/ND-CP dated January 10, 2022, detailing the implementation of a number of articles of the Law on Environmental Protection.

Based on the practical experience of plastic waste management in Vietnam and international experience, WWF has made specific recommendations to develop a recycling cost standard Fs for Vietnam. According to WWF, in Appendix XXII, Decree No. 08/2022/ND-CP has stipulated recycling solutions that are considered valid. However, considering the case of PE fiber production, it can be seen that the cost of forming PE fiber is much higher than the cost of forming plastic pellets. Or, in the case of recycling PET bottles, simply producing cleaned plastic flakes costs much less than producing recycled plastic pellets. In this case, the recycling cost standard should be applied to only one basic technology to produce recycled plastic pellets for plastic packaging.

Regarding the recycling cost norms for each product, the packaging that must be collected and recycled as listed in Appendix XXII is different even within each product group using the same recycling technology, due to the dependence on the pre-treatment and cleaning of the scrap. In case the scrap is cleaned before being transferred, the recycling facility does not need to operate those stages in the chain, and therefore the recycling cost will be lower.

According to WWF, to support the management and monitoring of the operation of the EPR system, it is necessary to issue recycled product standards, because with different product requirements (additional additives, additional refining and cleaning processes), the recycling costs are also different. In addition, it is necessary to issue economic and technical norms for the classification, collection and transportation of waste products and packaging because this will be an important content for local management agencies to effectively implement the classification and collection system of solid waste.

At present, because this economic and technical standard has not been issued, the cost is provisionally calculated from the operation of the private waste collection system that is currently operating effectively.

Vietnam also needs to consider adjusting the recycling cost standards in the direction that products that are being recycled effectively will apply low Fs, while products that are not being recycled effectively or have not been recycled in Vietnam will apply high Fs.

One issue to consider is that among packaging materials, the cost of recycling plastic is quite low compared to paper, and therefore if Fs is high, it will cause a trend for manufacturers to switch from paper packaging to plastic packaging to reduce costs. Thus, this conversion will be contrary to the view of EPR as well as the current direction of reducing the use of plastic packaging as stipulated in Article 73 of the Law on Environmental Protection 2020.

To overcome this point, the Consulting Group of the Institute of Environmental Science and Technology, Hanoi University of Science and Technology has proposed a coefficient considering the recycling efficiency. Accordingly, the types of products and packaging that are being recycled effectively and popularly in Vietnam today such as paper packaging, aluminum packaging, hard PET packaging... will have a small coefficient (and therefore, Fs will be low). On the contrary, products and packaging that have not been collected and recycled effectively such as iron packaging, hard plastic packaging, mixed paper packaging, soft packaging of all kinds... will have a higher coefficient.

In subsequent 3-year Fs adjustment periods as stipulated in Clause 5, Article 78 of Decree 08/2022/ND-CP, enhanced charging criteria should be considered, including recycling rates and the presence of certain types of hazardous substances or high filler content in plastic packaging products.

According to regulations, although it is a cost to support the activities of classifying and collecting waste products and packaging, currently because there are no specific technical instructions issued, determining the costs of classifying, collecting and transporting is only relative to support the private collection system to operate effectively and directly connect this system with recycling facilities.

When the local waste classification and collection infrastructure system is built according to the Law on Environmental Protection 2020 from January 1, 2025, this cost will need to be recalculated to match the estimated cost of classification, collection, transportation and treatment of solid waste corresponding to the requirements of the Law on Environmental Protection 2020.

Another essential element is the need for an appropriate regulatory framework to discourage the operation of informal recycling facilities, i.e., to limit the flow of waste products into the system. This can be done through the adoption of standards for recyclable materials or recycled products. These standards, if developed and enacted, would help to direct the flow of waste into the formal recycling system.

Source

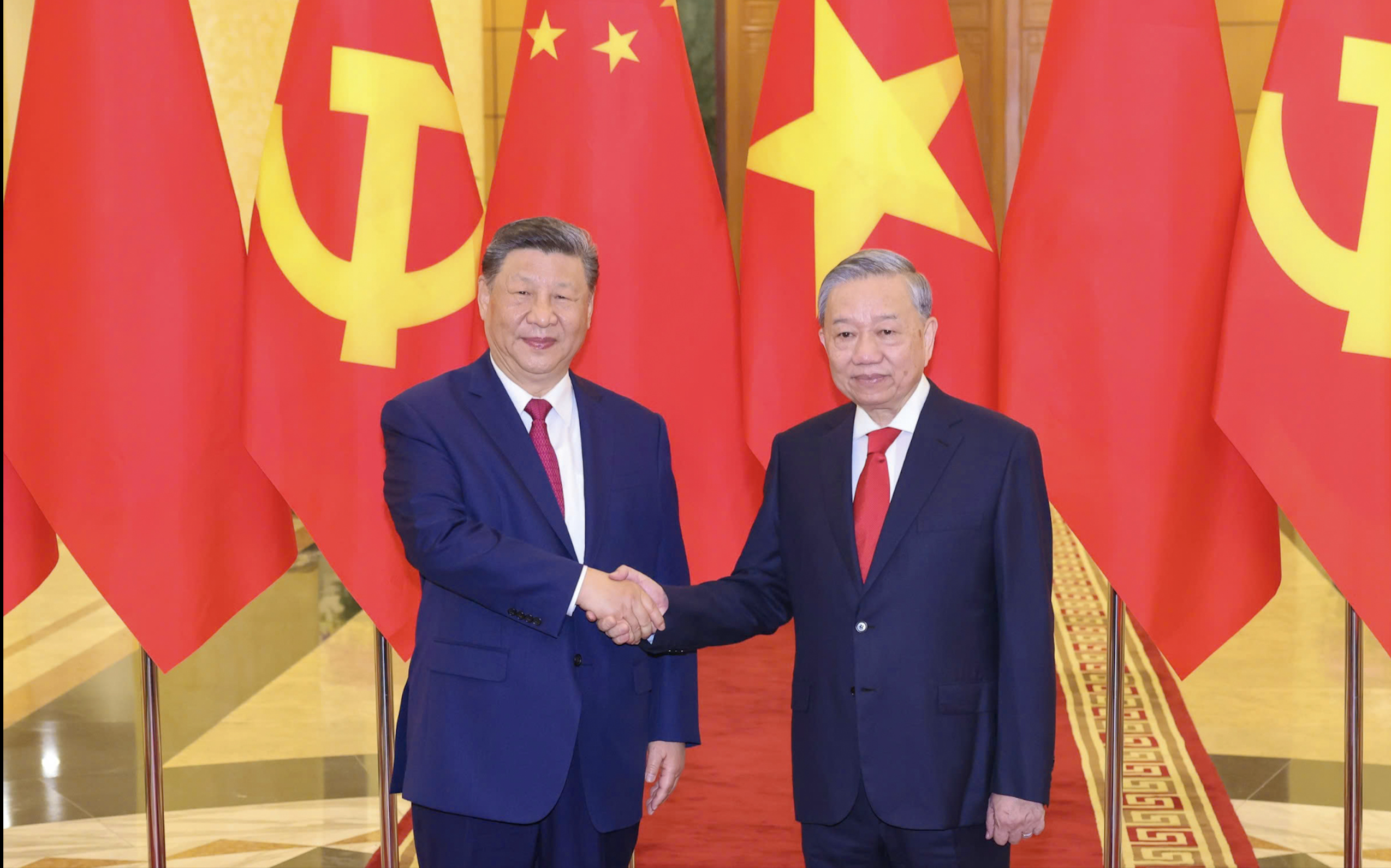

![[Photo] Reception to welcome General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/15/ef636fe84ae24df48dcc734ac3692867)

![[Photo] Tan Son Nhat Terminal T3 - key project completed ahead of schedule](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/15/85f0ae82199548e5a30d478733f4d783)

![[Photo] National Assembly Chairman Tran Thanh Man meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/4e8fab54da744230b54598eff0070485)

![[Photo] Prime Minister Pham Minh Chinh meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/893f1141468a49e29fb42607a670b174)

Comment (0)