Not taking full advantage of the opportunity

To date, Nghe An has more than 40 projects and production facilities, of which 30 factories are in operation and 10 projects have been granted investment policies and are under construction. Of these, 17 are foreign-invested projects with registered capital of 90.94 million USD. Garment factories have contributed to creating many jobs for workers in rural areas, with a total workforce of about 26,000 - 27,000 people.

Currently, there are 2 yarn and accessory production facilities in the province. That is, Vinh Yarn Factory with an annual production capacity of 16,000-18,000 tons of various types of yarn/year serving the domestic textile industry and export markets; 1 embroidery facility for accessories for garment factories in the province at Lac Son Industrial Park, Do Luong with a workforce of 200 people).

Garment manufacturing machinery and equipment technology and yarn production technology are mainly imported from China and Japan to produce export products to the US, South Korea and EU markets, etc. Although textile and garment export turnover has slowed down, it still contributes greatly to the total export turnover of the province.

In the first 9 months of 2023, in the context of many complex fluctuations in the world, textile and garment export turnover still accounts for 18.2% of the province's total export turnover of goods. It is expected to reach about 430 million USD in 2023 (down 6.07% over the same period).

The textile and garment industry has made an important contribution to the industrialization, modernization and economic restructuring of localities, creating more jobs for rural workers. Maintaining its leading role in export and investment attraction, textiles and garments annually account for 20-25% of the total export turnover of the province. Goods are exported to more than 30 markets around the world with a rich and diverse range of goods.

However, the supporting industry for the textile and garment industry is still lacking and weak. Raw materials are mainly imported from China, Japan, and Korea; There is no center for raw materials to serve the garment industry. There is no weaving project, so the yarn products produced are mainly for export to West Asia, the Middle East and for sale outside the province.

Garment enterprises are mostly small and medium-sized, the main production method is processing according to orders, so they are passive in planning production and recruiting labor. The textile and garment industry is starting to face difficulties with the scarcity of labor resources, including unskilled labor, due to the competitiveness in salary regime with other industries such as electronics, leather and footwear, etc. that have developed rapidly in recent times.

Garment factories are mostly concentrated in rural areas for easy recruitment of workers, however, they have difficulty recruiting skilled and qualified human resources.

In particular, although basic goods meet the origin criteria under free trade agreements (FTAs), to take advantage of tariff reduction benefits from new generation FTAs such as CPTPP (Comprehensive and Progressive Agreement for Trans-Pacific Partnership) or EVFTA (Vietnam-EU Free Trade Agreement), enterprises must prove the origin of production in Vietnam or other countries within the agreement from the yarn stage onwards for CPTPP, from fabric onwards for EVFTA. In reality, most of Vietnam's orders are sewn in the form of processing, the fabric source is mainly imported, so meeting the origin requirement from yarn onwards is quite difficult.

For EVFTA, the requirements for product materials are very strict, while the high-quality textile materials produced in Vietnam are currently not enough to meet the needs of businesses. Although businesses can use imported raw materials from outside the bloc from EVFTA-approved markets such as Korea, Japan, etc., the cost is too high. Therefore, only a few textile and garment businesses with very small shipments can take advantage of the new generation of FTA agreements.

What to do to take advantage of opportunities from FTAs?

In recent times, along with Vietnam’s implementation of FTAs, especially new generation FTAs, textiles and garments have become one of Nghe An’s key export products with large turnover and steady growth over the years. However, most businesses are still operating in the form of processing, without a brand, and with limited value. Therefore, supporting businesses to improve their competitiveness and build their own brands to meet export market standards is extremely necessary.

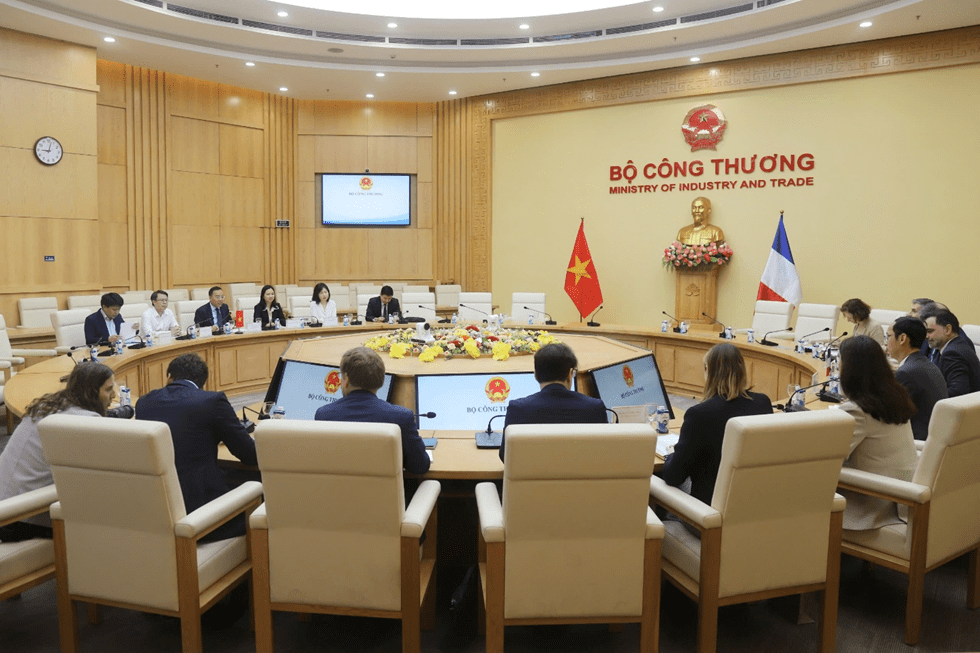

Recently, at a workshop discussing plans to take advantage of new generation FTAs in Nghe An, Mr. Ngo Chung Khanh - Deputy Director of the Multilateral Policy Department, Ministry of Industry and Trade said: Textile and garment is considered an essential manufacturing industry in the world, the fluctuations of this industry depend on each stage of the market and the competitiveness of Vietnamese enterprises. The scale of the global textile and garment market is expected to continue to increase strongly, under the impact of FTAs, it will create motivation for developing countries like Vietnam to have the opportunity to compete in the world market.

Sharing about the problems that Vietnamese enterprises face when taking advantage of FTAs, Mr. Ngo Chung Khanh said that currently, Nghe An textile and garment export enterprises are only focusing on the East Asian market; the European market is low, accounting for only 6.5% of the market share. Focusing too much on the near market will not be very effective.

The Deputy Director of the Multilateral Policy Department raised the issues that businesses face when taking advantage of FTAs such as: Not taking advantage of FTAs effectively; Lacking and being weak in capital, technology, capacity, mainly processing. Still having a “raw” mindset, not focusing on branding, not paying due attention to sustainable development issues…

From the business perspective, it is necessary to position the new generation FTA regional market in the export strategy to optimize costs and production capacity through connections with other businesses. Research information and policies of FTA regional markets, and develop strategies to approach these markets.

Sharing about the solution to take advantage of FTA opportunities of enterprises, Ms. Hoang Thi My Linh - representative of Hoang Thi Loan Textile and Garment Joint Stock Company said that for a long time, 80% of the enterprise's products have been exported to the Egyptian market, but since the end of 2022, it has been very difficult due to the market, delayed orders, high inventory, etc. Promoting the strengths of Nghe An, in the near future, the company will develop environmentally friendly products such as bamboo, recycled materials, etc. to export to European and FTA markets.

On the industry side, Mr. Cao Minh Tu - Deputy Director of the Department of Industry and Trade said: In order for the textile and garment industry in the province to develop sustainably and effectively, the province needs to prioritize attracting investment in stages that create high added value based on smart and automated production processes, focusing on attracting investment in industrial projects supporting the textile and garment industry with product groups: Fiber, fabric production from domestic fibers, raw materials for the garment industry to form a value chain for the textile and garment industry in the province and improve product competitiveness.

Along with that is the reasonable distribution of textile and garment enterprises, ensuring favorable conditions for labor supply, transportation, logistics infrastructure, etc. Continue to promote support for textile and garment enterprises in digital transformation, market expansion, brand building and development, etc. through industrial promotion, trade promotion, and supply-demand connection activities. Continue to support investors in training and labor recruitment; provide in-depth training for enterprises to effectively apply the rules of origin of textile and garment products to boost exports.

Source

![[Photo] Overcoming all difficulties, speeding up construction progress of Hoa Binh Hydropower Plant Expansion Project](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/12/bff04b551e98484c84d74c8faa3526e0)

![[Photo] Closing of the 11th Conference of the 13th Central Committee of the Communist Party of Vietnam](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/12/114b57fe6e9b4814a5ddfacf6dfe5b7f)

Comment (0)