Besides the challenges in complying with regulations on green production and circular economy, domestic textile and garment enterprises also have great opportunities to penetrate deeper into billion-dollar markets if they have clear origin of goods and protect the environment.

Businesses face many challenges

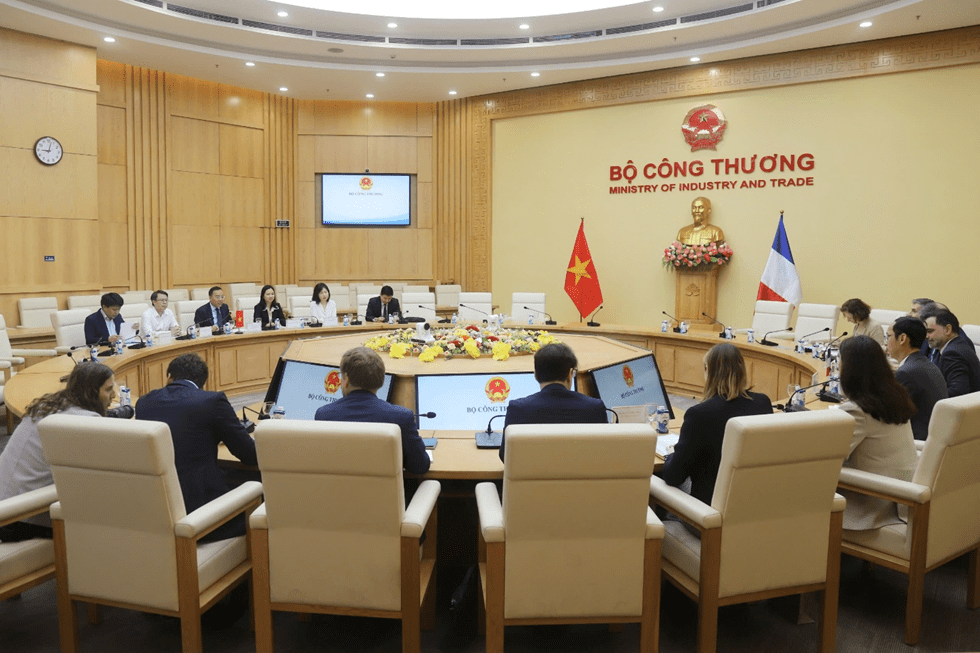

Sharing at the National Conference on Sustainable Production and Consumption 2024 organized by the Ministry of Industry and Trade on September 19 in Da Nang, Mr. Nguyen Duc Tri, Vice President of the Association Textile Vietnam (VITAS) said that countries are increasingly demanding more stringent requirements for textile products. Accordingly, textile products must meet standards related to carbon emissions, safe use of chemicals and recycled raw materials. These new regulations force domestic enterprises to shift to cleaner production processes such as using clean energy, renewable energy, recycled materials and minimizing waste in production.

To adapt, many textile and garment enterprises have invested in niche markets through the production of recycled fabrics from PET plastic, recycled cotton, or sustainable fibers such as bamboo fiber, fiber from tree bark. The shift to sustainable consumption and production promotes circular economy causing businesses to face many difficulties due to having to change technology and production processes. The cost of converting production is a burden for many Vietnamese textile and garment enterprises, especially small and medium enterprises.

According to Mr. Tri, to convert to sustainable consumption production to promote the circular economy, businesses need to invest heavily in technology, wastewater treatment systems, energy saving and the use of recycled materials... Along with the conversion, production costs also increase sharply because recycled fabrics, organic cotton and non-polluting materials are often more expensive than traditional materials and their supply is still scarce. Costs, handling of waste management issues and supply chains of textile and garment businesses are also significant challenges for businesses in the process of "greening" production.

“Some businesses only see green production and circular economy as a way to meet international requirements instead of considering it as a long-term strategy. The lack of sustainable supply chain management skills is also a major obstacle for businesses,” said Mr. Tri.

Besides the “greening” standards, according to businesses, the biggest difficulty at the moment is the development strategy and costs to transform production processes and supply chain operations. In reality, there is currently no unified global standard on sustainable production applicable to the textile and garment industry, leading to difficulties in assessing and ensuring the sustainability of supply chains and products.

In addition to production transformation, according to the representative of the Vietnam Textile and Apparel Association, enterprises need to invest in developing and expanding domestic textile raw materials such as recycled fibers and environmentally friendly fabrics. Developing these raw material sources will help reduce dependence on imported raw materials, while meeting the strict requirements for sustainable products of the international market. Textile and garment enterprises also have more opportunities to access larger and more sustainable markets such as the EU, the US, and Japan.

According to the Strategy for the development of the Vietnamese textile and footwear industry to 2030, with a vision to 2035, the Vietnamese textile and garment industry will develop sustainably according to the circular economic model. The government will have support programs on preferential loans, tax incentives for green production projects and training programs to help businesses have easier access to sustainable technology and solutions.

Must know how to seize opportunities

According to the Vice President of the Vietnam Textile and Apparel Association, in addition to difficulties, regulations on green development, clean production requirements, and circular economy are also opportunities to help textile and garment enterprises enhance brand value and competitiveness in the market.

“For businesses that proactively and seriously transition to a circular economy, sustainable production and consumption have created a difference for their businesses in the market, thereby enhancing the value of their brand and increasing profits,” said Mr. Tri.

According to the general director of a large textile and garment enterprise, the transition to green production and the implementation of a circular economy are also opportunities to promote innovation and creativity, and enterprises can take advantage of opportunities to create new environmentally friendly products. However, this requires determination and efforts from the top leaders of enterprises and support from the Government, ministries and localities in training high-quality human resources and labor training, supporting consulting on science and technology, transferring green production technology, circular production, and providing preferential loans to support enterprises to accelerate the transformation process.

Source

![[Photo] Closing of the 11th Conference of the 13th Central Committee of the Communist Party of Vietnam](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/12/114b57fe6e9b4814a5ddfacf6dfe5b7f)

![[Photo] Overcoming all difficulties, speeding up construction progress of Hoa Binh Hydropower Plant Expansion Project](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/12/bff04b551e98484c84d74c8faa3526e0)

Comment (0)