When the gate of Nestlé Binh An factory opened, the group of visitors immediately saw the factory campus with rows of green areca trees hugging the factory wall. Notably, Nestlé Binh An factory is located in Amata Industrial Park (Bien Hoa City, Dong Nai), one of the first three industrial parks in Vietnam chosen to build a global ecological industrial park.

Therefore, not only inside the factory but also along the roads inside the industrial park are covered with green grass and trees, completely different from the image many people have of industrial parks with corrugated iron roof factories located close together.

Leading us into the Training Center, Mr. Phung Huu Cung, director of Nestlé Binh An factory, instructed experts, students and members of the delegation on how to handle situations to ensure safety during the tour, a mandatory procedure for everyone when coming to the factory with a very Vietnamese and meaningful name - "Binh An" factory.

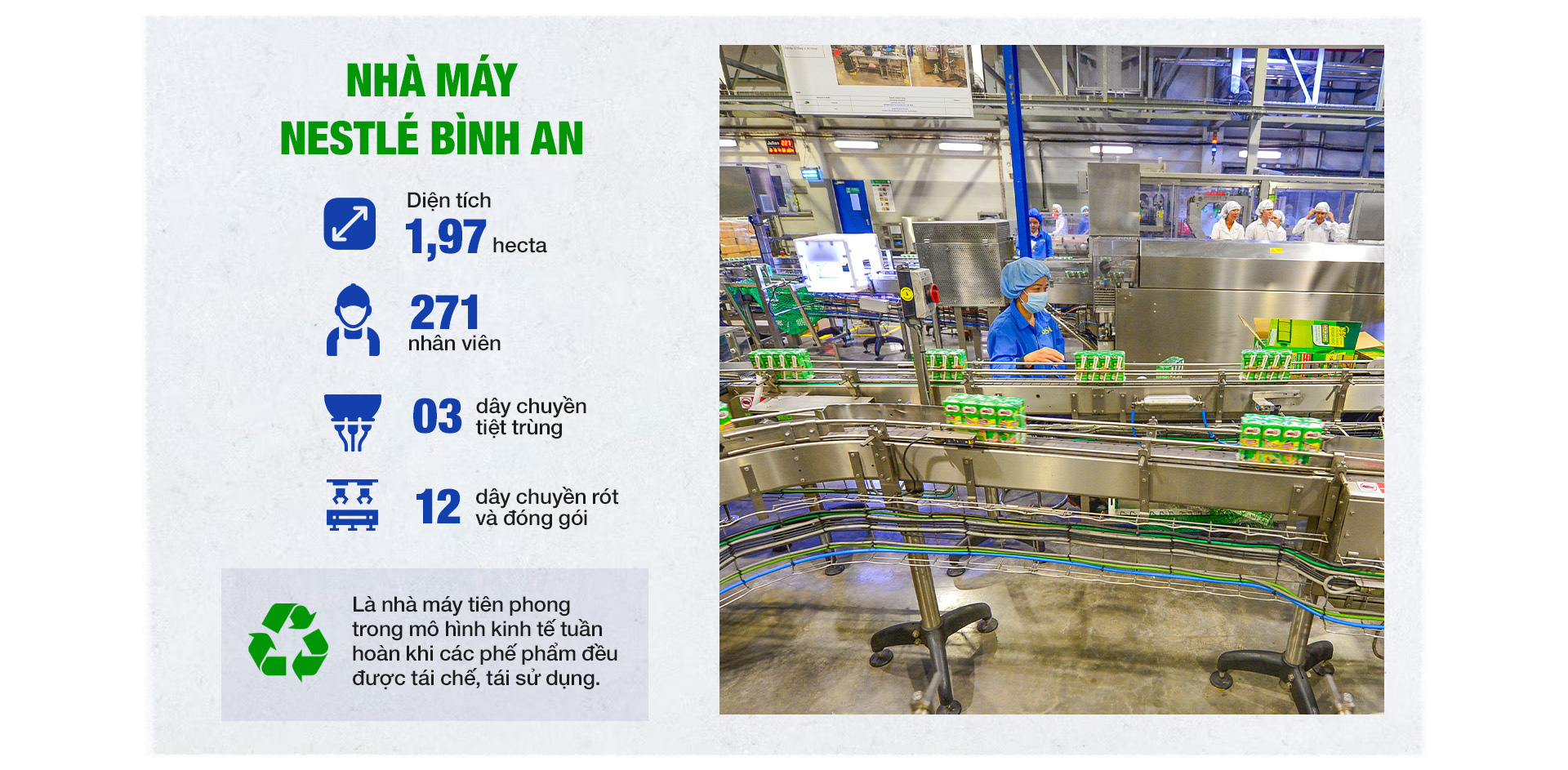

According to Mr. Cung, Nestlé Binh An factory covers an area of 1.97 hectares with 271 employees. This is a modern factory with 3 sterilization lines and 12 filling and packaging lines. Notably, this is a pioneer factory in the circular economy model where all waste products are recycled and reused.

At this factory, the paper straws attached to Milo milk cartons are all FSC certified paper straws, the packaging used is Tetra Ultra packaging and POF film. According to Mr. Cung, this factory also has high energy saving efficiency when the production cycle has been optimized from 24 hours to 144 hours, helping to reduce 3.5 times the amount of water used compared to the old process, reduce the use of chemicals by 3 times compared to before, and reduce electricity consumption by 4 times compared to before.

Directly guiding the Green Vietnam program's visitors to the energy management area, Mr. Cung said that this factory has applied digitalization in energy management by using DMO Energy - an energy measurement and management system, helping to control over 80% of energy. At the same time, the factory also applies artificial intelligence (AI) technology to control air compressors, helping to reduce electricity consumption by up to 220,361 kWh/year.

In the wastewater treatment area, Mr. Cung said that this is a typical area of the circular economy when the factory's wastewater has been reused. Specifically, thanks to Purity advanced treatment technology, up to 46.4% of wastewater from the production line of Nestlé Binh An factory is treated to meet the World Health Organization (WHO) drinking water quality standards for reuse for some activities in the factory such as cleaning the factory, supplying water to boilers, cooling towers, helping to reduce up to 44,373 m³/year.

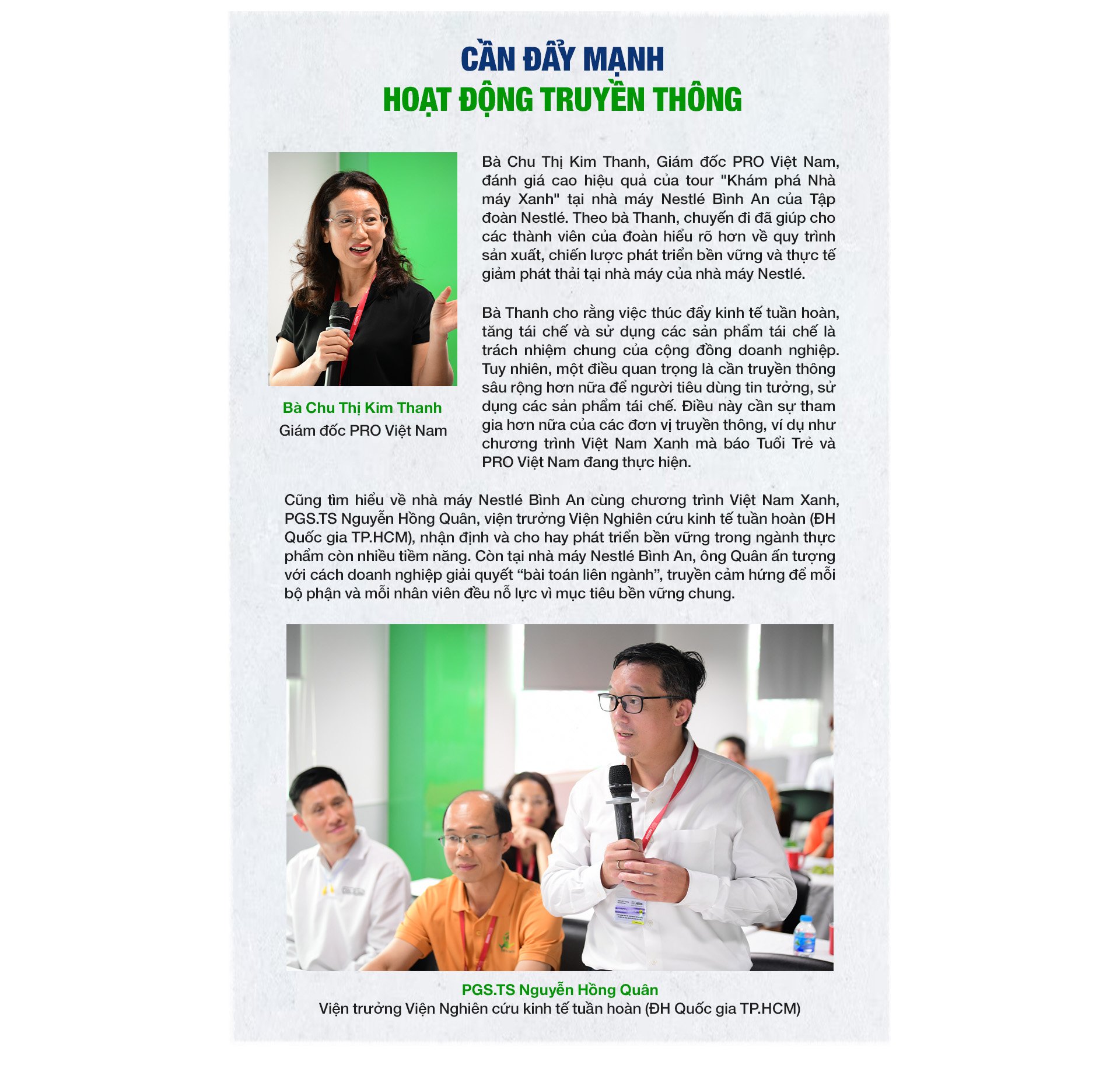

One surprising point for experts of the Green Vietnam program is the space displaying products made from recycled materials from factory waste.

Holding a plastic roofing sheet, Mr. Nguyen Thanh Son - the tour leader - was surprised when the staff of Nestlé Binh An factory introduced that it was produced from recycled waste from milk cartons. In addition, milk cartons are also recycled into cardboard boxes. And the sludge from the wastewater treatment system is also produced into organic fertilizer by Nestlé factory partners.

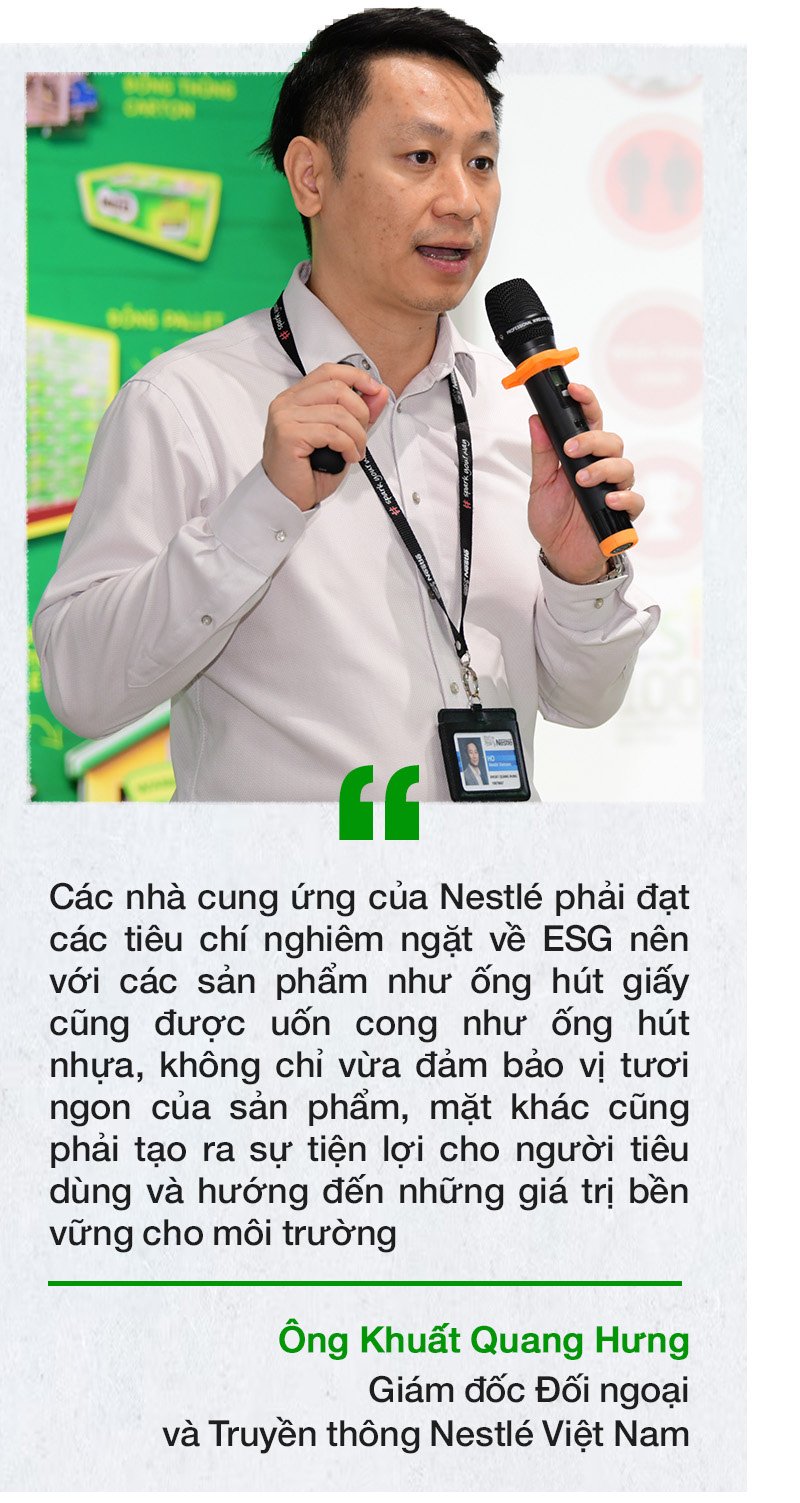

Entering the product packaging area with dozens of paper straws attached to Milo milk cartons in a modern production line, Mr. Khuat Quang Hung - Director of External Affairs and Communications of Nestlé Vietnam - said that replacing plastic straws with paper straws is a dramatic change for this product.

According to Mr. Hung, with the desire to reduce plastic waste, after a long period of research, Nestlé has brought to consumers a new type of straw made from paper to replace traditional plastic straws. Milo paper straws can be bent, have no paper smell, so they do not affect the taste and quality of milk. Above all, this straw is also improved to maintain its hardness for a longer time.

Mr. Hung believes that not only ensuring food safety and good usability, paper straws are also environmentally friendly with FSC certification, meeting the criteria for sustainable development, balancing environmental protection values with social benefits.

"Nestlé suppliers must meet strict ESG criteria, so products such as paper straws are also curved like plastic straws, not only ensuring the freshness of the product, but also creating convenience for consumers and aiming for sustainable values for the environment," said Mr. Hung.

Holding a Milo milk carton in his hand, Mr. Hung said that with these milk cartons, Nestlé cooperates with partners to be able to recycle 100%. According to Mr. Hung, since 2019, Nestlé Vietnam has become one of the founding enterprises of the Vietnam Packaging Recycling Alliance (PRO Vietnam), since then, together with PRO Vietnam and recyclers, they have increased the implementation of activities and projects to increase the collection rate of used packaging through programs implemented in schools, communities, etc. to create a new life cycle for the product.

Talking about Nestlé's sustainable development strategy in Vietnam, Mr. Hung said that Nestlé Vietnam Co., Ltd. was established and construction of the Dong Nai Factory started in 1995. Up to now, Nestlé has had nearly 30 years of development in Vietnam with more than 2,200 employees and 4 factories nationwide.

According to Mr. Hung, Nestlé always attaches importance to the principles of sustainable development in production and business activities associated with the implementation of social responsibility. 2023 also marks the milestone of 3 consecutive years that Nestlé Vietnam has led the Top 100 "Sustainable Enterprises" in the manufacturing industry. Mr. Hung said that Nestlé has pioneered with strong actions in promoting the implementation of the circular economy model, regenerative agriculture, innovation and digital transformation in an effort towards a green economy and sustainable development in Vietnam.

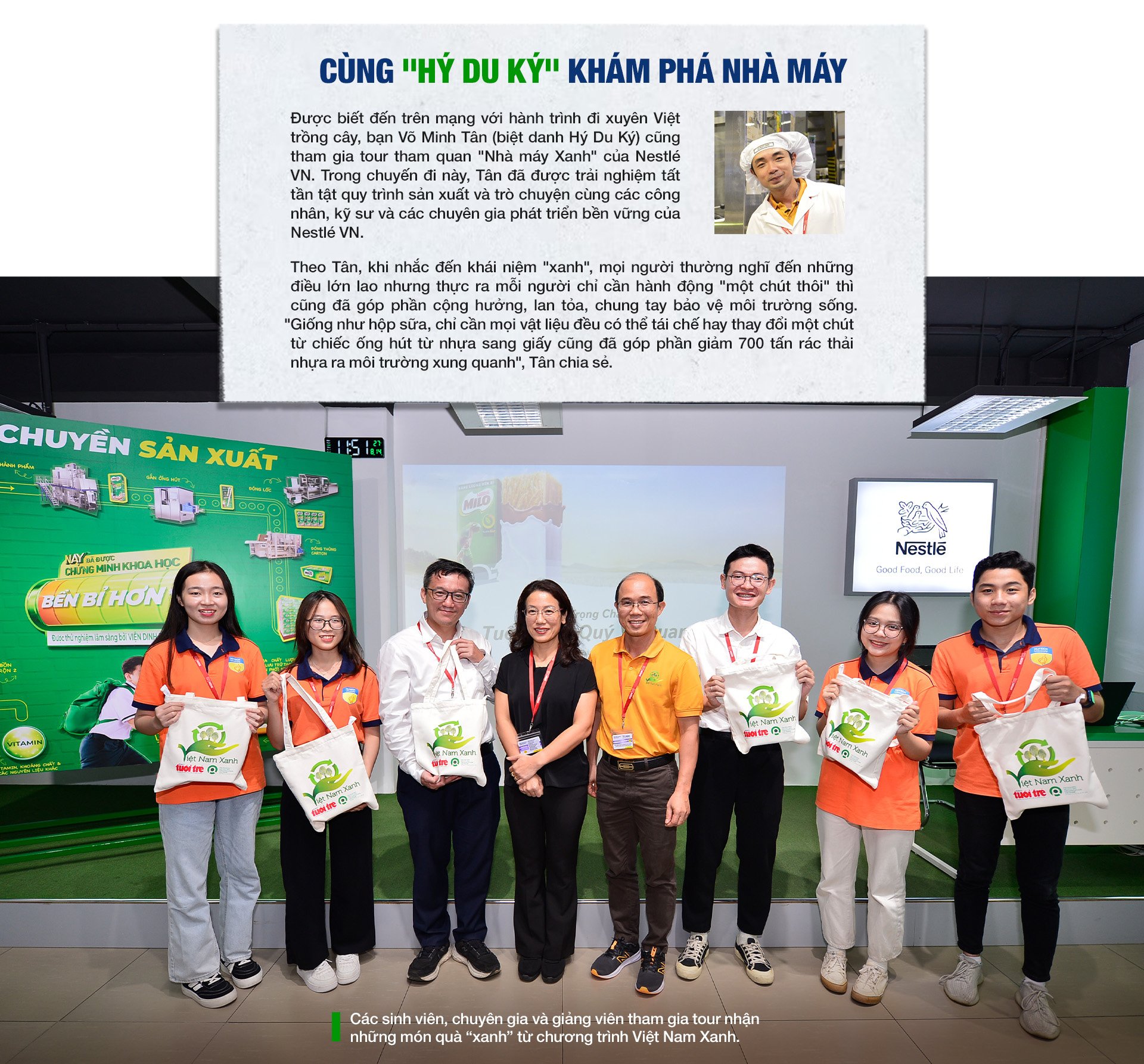

In addition to sustainability experts, the delegation also included lecturers and students from universities in Ho Chi Minh City. During the tour, lecturers and students witnessed the production and packaging processes and listened to engineers share their practical experiences in their daily work with the professions that the students were studying.

Right at the factory, students' questions about technology, quality and sustainable development orientation were thoroughly explained by Nestlé Vietnam representatives.

Student Dao Ha Thanh Lam (HUTECH University) said that participating in the tour of the Nestlé factory, he was truly impressed by the scale of production and the company's strong commitment to building a sustainable future.

"Every step in the factory is an interesting discovery about the modern production process and the tireless efforts to protect the environment. The tour of the Nestlé factory has inspired my belief in a sustainable future. I hope that many other businesses will join Nestlé, joining hands to protect the planet," Lam shared.

Meanwhile, student Vo Huynh Nhu said that from the moment she set foot in the factory, she was impressed by the green, vibrant space. From the use of renewable energy, the advanced wastewater treatment system to the carbon-free production process... everything is done professionally and responsibly towards the environment.

Talking to Tuoi Tre , Master Nguyen Vu Phong (HUTECH Institute of Applied Sciences) shared that the tour at Nestlé Binh An Factory and learning about the "Eco Friendly" technology solution are the most practical lessons, helping students raise awareness of environmental protection, and apply it more smoothly in their future work.

"From the unique experiences at the factory, you will be more sensitive in coming up with a series of solutions to help improve environmental quality in the 4.0 era," said Master Phong.

QUANG DINH

Source: https://tuoitre.vn/tour-kham-pha-nha-may-xanh-den-nestle-binh-an-20240825145727136.htm

![[Photo] "Beauties" participate in the parade rehearsal at Bien Hoa airport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/155502af3384431e918de0e2e585d13a)

Comment (0)