Competing with China, building an electric vehicle supply chain, and avoiding mass layoffs are challenges for the auto capitals of Slovakia and the Czech Republic.

Dubbed the “Detroit of Europe,” Slovakia and the Czech Republic are the world’s two largest car producers per capita. In this metropolitan area, the auto industry plays a pivotal role in the economy.

Car manufacturing is Slovakia's largest industry, accounting for 13% of GDP (while Germany accounts for only 5%), with major brands having factories such as Volkswagen, Peugeot, Kia, Jaguar Land Rover. By 2022, the country will produce more than one million cars, or an average of 184 cars per 1,000 people. More than 30% of Slovakia's annual exports come from cars and related engines and machinery.

In the Czech Republic, the automotive industry also accounts for about 10% of GDP and a quarter of exports. The country plays an important role in the European automotive industry, hosting factories for Skoda, TPCA and Hyundai. Over the past two decades, thanks to the automotive industry, growth in the Czech Republic and Slovakia has reached 2.4% and 3.5% respectively, higher than the EU average.

But the electric vehicle wave is threatening the future of this auto capital. There are at least two main challenges facing the region. The first is the wave of electric vehicles "Made in China".

Data from the Center for Strategic and International Studies (CSIS) in Washington (USA) shows that China's electric vehicle exports to Europe have increased steadily every year, from 621.5 million USD in 2019 to more than 15 billion USD in 2022. In the first 7 months of 2023 alone, it reached more than 13 billion USD.

CSIS said most electric vehicles imported from China arrive at ports in Belgium, the Netherlands or Slovenia, but are then sold in the UK, Germany or Scandinavia. Most Chinese electric vehicles enter Europe thanks to high demand and low import tariffs, while the US levy of 27.5% makes them difficult to penetrate.

According to a study by German insurance company Allianz, if Chinese car imports to Europe reach 1.5 million units by 2030, the economic loss for the European auto industry will be 24.2 billion euros. Economies heavily dependent on this industry such as Slovakia and the Czech Republic could suffer a larger impact, ranging from 0.3% to 0.4% of GDP.

“If we say that China is bad at producing combustion engine cars, this is no longer true for electric cars,” Patrik Križanský, director of the Slovak Electric Vehicle Association (SEVA), told EURACTIV Slovakia.

Allianz suggests that policymakers should pursue reciprocal trade cooperation with China. “Furthermore, allowing Chinese investment in auto assembly could create more value added,” the company recommends.

In a recent effort to protect its auto industry, the European Commission has opened an investigation into several Chinese electric vehicle manufacturers to see if they are benefiting from subsidies to sell at lower prices. France has published a list of electric vehicles eligible for subsidies, excluding most Chinese vehicles.

European manufacturers themselves are accelerating electrification, but that process also threatens the “Detroit of Europe.” Several multinationals have announced major investments in Slovakia from 2022, including more than €1.2 billion from Volvo for a third factory in the country to produce electric cars. Porsche is also planning to spend €1 billion to produce battery modules for electric cars.

Zuzana Zavarská, an economist at the Vienna Institute for International Economic Studies (WIIW), confirmed that foreign companies are driving Slovakia's transformation through large investments. "On the other hand, domestic companies are lagging behind in the transformation process, which requires the country to take a more assertive approach to industrial policy," she commented in Emerging Europe .

Most car engines produced in Slovakia are still conventional combustion engines. Electric engines require fewer parts and are simpler to manufacture. This means fewer workers are needed to maintain the same car output.

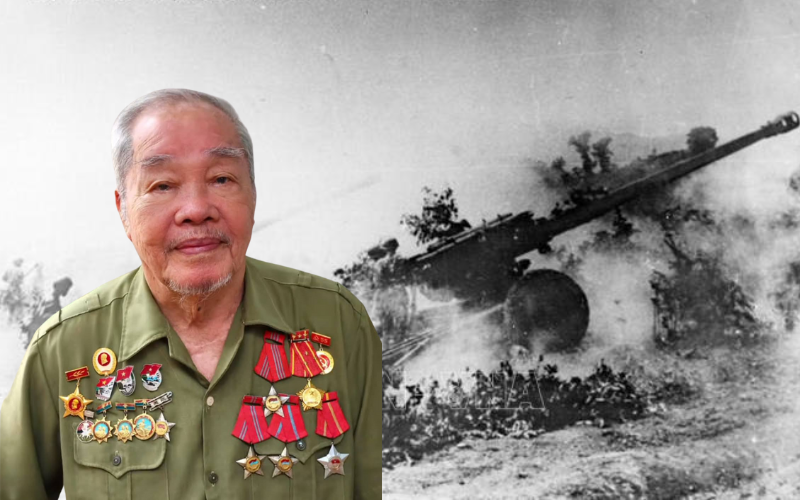

Workers work on a Volkswagen Porsche production line in Bratislava, Slovakia in July 2019. Photo: Reuters

A total of 260,000 people work at four carmakers and 350 suppliers across Slovakia. In the Czech Republic, that number is almost double. In a worst-case scenario, up to 85,000 jobs, or 4.5% of the workforce, could be eliminated by switching to electric vehicles, according to research by Bratislava-based think tank Globsec.

“If we don’t manage this transition, we will have a problem with jobs,” Alexander Matusek, chairman of the Slovakian Automotive Industry Association (ZAP), told Bloomberg.

Another concern for the future of the Czech Republic and Slovakia is the risk of falling behind in attracting investment to build electric vehicle battery plants. Hungary and Poland have nearly a dozen factories built or under construction. The problem, says Vazil Hudak, Slovakia’s former economy minister and vice chairman of Globsec, is that when automakers choose to expand, they may direct new production to areas close to battery suppliers.

As of mid-last year, Reuters counted just two electric vehicle battery projects in the Czech Republic and Slovakia. Of these, Magna Energy Storage ( MES ) was operating a $64.5 million plant with an initial production capacity of 200 MWh per year in the Horní Suchá region. The company hopes to increase that to 15 GWh in the future. Meanwhile, Slovakia only had a 45 MWh pilot production project by InoBat.

In 2022, Volkswagen was looking at possible locations for an electric car battery factory in Eastern Europe. The group considered the Czech Republic, Hungary, Poland and Slovakia. This would be the group's fourth battery factory if it were approved.

However, as of November 2023, CEO Oliver Blume said the Volkswagen Group had not yet decided on a location for the factory due to lower-than-expected demand for electric vehicles in Europe. In the Czech Republic, the group has a subsidiary called Skoda. The government had tried to convince Volkswagen to choose it.

After Oliver’s announcement, Czech officials began offering the site for Volkswagen’s battery plant to other investors, as they could no longer wait. The site had been planned by the government for a gigafactory that would allow them to control the electric vehicle supply chain.

In November 2023, Industry and Trade Minister Jozef Síkela said he was in talks with five potential investors to build the megafactory. He did not name them but said they could come from other continents.

Phien An ( summary )

Source link

![[Photo] "Beauties" participate in the parade rehearsal at Bien Hoa airport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/155502af3384431e918de0e2e585d13a)

![[Photo] Looking back at the impressive moments of the Vietnamese rescue team in Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/5623ca902a934e19b604c718265249d0)

![[Photo] Summary of parade practice in preparation for the April 30th celebration](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/78cfee0f2cc045b387ff1a4362b5950f)

Comment (0)