In an interview with Nhan Dan Newspaper, Mr. Tran Dang Hoa, Chairman of FPT Information System Company (FPT IS) and Chairman of FPT Semiconductor Joint Stock Company (FPT Semiconductor) - a member company of FPT Group, said that chips are the core of the digital economy.

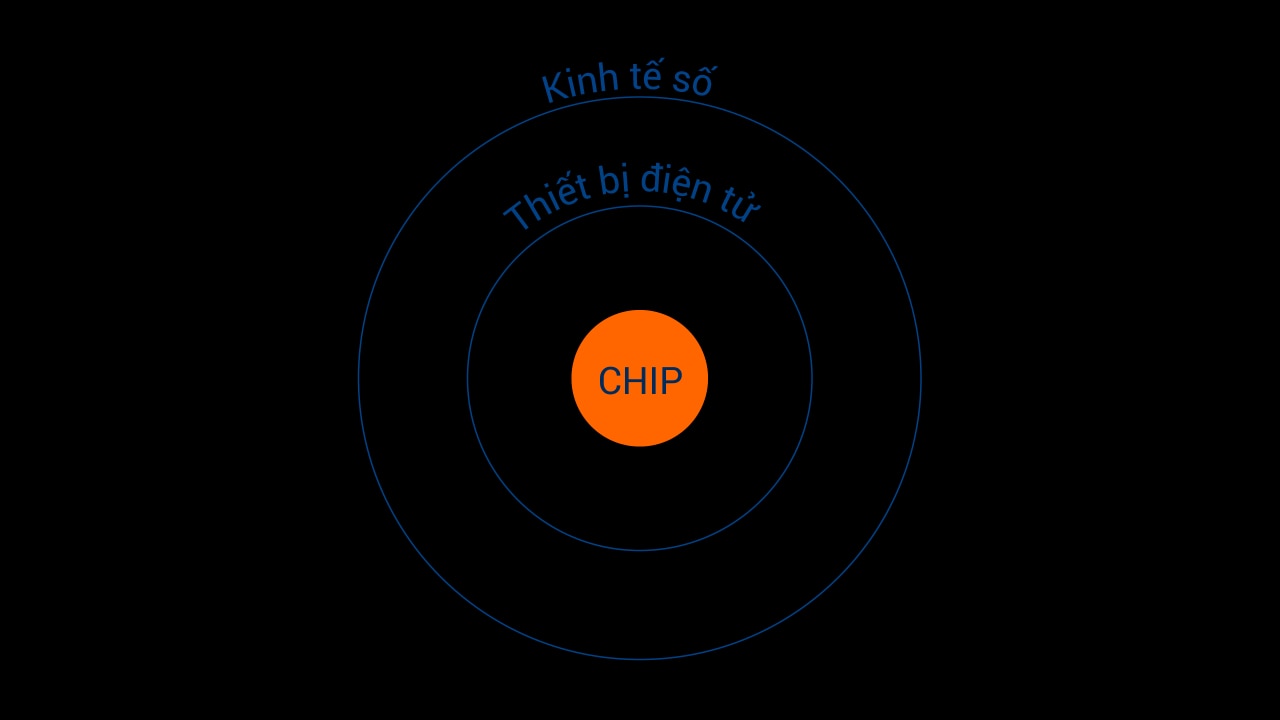

Using the image of three concentric circles, Mr. Hoa emphasized the importance of the chip industry. Accordingly, the first circle is the digital economy, the second circle is electronic devices, and the innermost core – the third circle is semiconductor chips.

If Vietnam wants to develop the digital economy and the electronics industry, developing the semiconductor industry is the most important thing.

In addition, the interview also revolved around many stories about the reasons and chip segments that are prioritized for production in Vietnam.

Chips are at the core of the digital economy

PV: From a business perspective, why do you think Vietnam needs to develop the semiconductor chip industry at this time?

Mr. Tran Dang Hoa: I have 3 circles like this: The first circle is the digital economy. The second circle within the digital economy is electronic devices. The innermost core - the third circle is semiconductor chips. If Vietnam wants to develop the digital economy, develop the electronics industry, then developing the semiconductor industry is the most important thing.

First, the number of Internet-connected devices is increasing rapidly. We estimate that a person may need at least 20 chips. Phones, televisions, refrigerators, etc. Each device requires dozens of chips. All electronic devices need chips. But 100% of electronic devices in Vietnam are using foreign chips. This is a very large market for developing domestic chips.

Second, Vietnam has a huge advantage in the semiconductor industry. Currently, there are 5 countries and regions in the world that are considered to have the ability to develop chips comprehensively: the US, Japan, Korea, China, Taiwan (China). Of these, 4 prominent names all have characteristics quite similar to Vietnam from culture, people to personality, ... These 4 countries and regions have all developed their countries with technology, have made chips. I believe that Vietnam will be the next name. On the other hand, Vietnam also has a great advantage in terms of people. Changes in geopolitics have also created opportunities for Vietnam, making Vietnam a potential candidate to fill the vacant position.

It takes just 6 months to transition a software engineer to chip maker.

PV: Specifically, what are Vietnam's human advantages, sir?

Grandfather Tran Dang Hoa: Vietnamese people are very good at math. We have built a software industry with 1 million employees. Vietnam's software industry is not inferior to the world's average. The transition from software to hardware will not have many obstacles.

On average, it takes FPT 6 months to 1 year to train and convert a software engineer to hardware and chip making.

Of course, the chip design process will have many stages. There are stages that still require 5, 10 to 20 years of human resource training. But there are also stages that are especially simple, requiring only 6 months to 1 year of training for engineers to be able to do.

Human resources for this industry are not picky but need to be meticulous and detailed. While many Korean and Japanese engineers do not like chip design because this industry is not very dynamic, many Vietnamese engineers have become famous in the field of chip design worldwide.

Focus on design instead of manufacturing

PV: When developing technology products in a developing country, investors often think about outsourcing. But why did FPT Semiconductor decide to go against this trend, focusing on the design stage instead of chip manufacturing?

Mr. Tran Dang Hoa: FPT has three priority technology pillars: One is AI, two is semiconductor chips and three is automotive software.

Chip manufacturing is a large-scale problem, with investment amounts reaching billions of dollars. Recently, the Korean government has established a chip manufacturing center with $471 billion. Japan and the US have also established many similar factories. This is a race that consumes a lot of resources that we can hardly afford to invest.

In addition to investment, Vietnam also has to compete. The larger the scale, the cheaper the cost, the higher the competitiveness. For example: A manufacturer of more than 1 billion chips/year like TSMC (Taiwan, China) will have very low production costs. But if a factory can only produce 1 million chips/year, the selling price will be very high. Therefore, latecomers like us will have many big barriers.

On the contrary, chip design mainly depends on people. Vietnam has a population of 100 million with many people good at math and programming. This is an important condition to establish a chip design team, creating an advantage for Vietnam when investing in chips.

Chip design is mostly dependent on people. Vietnam has 100 million people with a lot of people good at math.

However, to optimize the logistics process and increase the efficiency of the semiconductor industry, creating a seamless design-manufacturing chain is extremely important. Currently, we have to bring the chip design to Korea for manufacturing, to Taiwan for packaging. It is a very long journey.

If we have a manufacturing and packaging factory right in Vietnam, the domestic chip industry will save a lot of time, cost and production effort. Vietnam can do this by expanding cooperation with international partners like Intel… to bring manufacturing factories to Vietnam. We cannot do this alone.

Why mid-range chips ( 28 – 130 nm)?

PV: Sir, what chip lines is FPT Semiconductor currently focusing on?

Mr. Tran Dang Hoa: The first chip we produced was the power chip line. That is, the type of chip that specializes in power management. This is the chip that any device needs.

In 2022, the launch of the first microchip line applied in Internet of Things (IoT) products in the medical field is considered a breakthrough.

In 2023 and 2024, FPT Semiconductor will continue to design and manufacture IoT platform chips for smart device applications, IoT for agriculture, forestry, and fisheries.

Recently, we received orders for 70 million chips in 2024 and 2025 for customers in Taiwan (China), Korea and Japan in the fields of medical devices and electronic applications.

Currently, FPT Semiconductor is developing 25 chip lines. Most of these chip lines are mid-range technology with sizes ranging from 28nm - 130nm.

PV: Why does FPT Semiconductor only focus on chip lines with sizes from 28nm - 130nm, sir?

Mr. Tran Dang Hoa: We are focusing on popular chip lines with moderate technology. Because high technology has fierce competition. Meanwhile, many businesses do not want to invest in mid-range technology anymore.

In particular, these chip lines have suitable investment and production costs, competitive selling prices, so this will be the strategy for FPT Semiconductor to enter and succeed in this market.

Exclusive chip "tailoring" technology

PV: If we focus on the mid-range segment, what competitive advantages will FPT Semiconductor's chips have compared to chips in the same segment from other countries in the region? Or in other words, with the same 28-130nm chip, why would users want to choose FPT Semiconductor's chip, a Vietnamese chip?

Mr. Tran Dang Hoa: FPT Semiconductor’s big advantage is its ability to be flexible, customizable, changeable and “tailor-made” chips according to customers’ needs. Specifically, Taiwan (China) and many other countries often make the same chip model. Customers want to change, but they don’t change. Because instead of prioritizing the “tailor-made” chip field, these countries often only focus on high-tech chips. This is a niche market for Vietnam.

While other suppliers only design one power chip model for widespread sale, FPT Semiconductor can design separate power chips for each type of device, customized according to customer needs. For example: separate power chip for camera, separate power chip for phone, separate power chip for printer, etc.

It can be said that this is FPT Semiconductor's exclusive competitive technology up to now.

However, this market is not too big but it takes a lot of work. Luckily, Vietnam has a big advantage in human resources.

Currently, only 5 countries in the world have the ability to produce chips. However, the remaining 4 countries all have average incomes 10 times higher than Vietnam. Therefore, the cost of paying labor is cheaper than all the other countries.

PV: As you said, 100% of electronic devices in Vietnam are using foreign chips. Why are Vietnamese chips not competitive in the domestic market, sir?

Mr. Tran Dang Hoa: Firstly, in the past, Vietnam had many other business opportunities than making chips.

Second, the major geopolitical changes taking place in the world have changed the chip industry landscape. Previously, this market was stable, suppliers were all firmly established, there was no gap for Vietnam to enter. Because the market was stable, there were no more domestic suppliers. Therefore, we also did not have domestic chips.

More importantly, as I said at the beginning, Vietnam has to develop the second circle - electronics so that domestic chip equipment can go into these products.

We already have international brands such as Samsung, LG, etc., but we still need more domestic electronics manufacturing companies.

Vietnam will be number one in Southeast Asia

PV: In your opinion, where can Vietnam stand in the Southeast Asian rankings?

Mr. Tran Dang Hoa: Vietnam will be number one in Southeast Asia and top 5 in the world in the chip industry.

However, to improve Vietnam's position on the world chip map, the private sector needs to bravely participate in this field. What we need is not 1-2 companies, 1-2 people but an entire industry with hundreds of companies.

We must turn Vietnam into a “market” with many choices. If investors do not like this company, they can immediately find another one. We must create domestic competition to increase Vietnam’s attractiveness on the world chip map.

However, this is a long-term journey that needs to be maintained for many years to be successful, avoiding half-hearted work.

PV: In your opinion, how many years will it take to complete this journey?

Mr. Tran Dang Hoa: Vietnam has a great opportunity for the semiconductor industry, but only for a few years (maybe the next 2 years). That will be the decisive step to complete the long-term goal (maybe in 20 years). Vietnam's roadmap includes many small stages, and to conquer each goal we need to act strongly, effectively and consistently. If this opportunity slips out of reach, Vietnam may have to wait a long time or never have the golden time like now again.

PV: Thank you very much./.

![[Photo] General Secretary To Lam receives Russian Ambassador to Vietnam](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/2/b486192404d54058b15165174ea36c4e)

![[Photo] Third meeting of the Organizing Subcommittee serving the 14th National Party Congress](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/2/3f342a185e714df58aad8c0fc08e4af2)

![[Video] Award ceremony of the contest "Denmark in your eyes 2024"](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/2/5204aa8890024b2e932f28393f139f27)

![[Photo] Relatives of victims of the earthquake in Myanmar were moved and grateful to the rescue team of the Vietnamese Ministry of National Defense.](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/2/aa6a37e9b59543dfb0ddc7f44162a7a7)

Comment (0)