The Fourth Industrial Revolution is becoming a reality, thanks in no small part to Industrial Internet of Things (IIoT) technology and private 5G networks. By 2029, the Fourth Industrial Revolution market is expected to reach a value of $377.30 billion.

5G: The Essential Connectivity Partner

Machines, robots, sensors, humans, and drones all need seamless connectivity in the IIoT. Previous generations of wireless networking technology have been unable to meet this massive demand for connectivity, which is why 5G is a key enabler for Industry 4.0. Not only does it enhance connectivity, it also provides a number of benefits that will help accelerate this revolution, including:

Faster data speeds and higher bandwidth

5G has data transmission speeds of up to 20 Gbps, 20 times faster than 4G. This allows for the rapid transmission of large amounts of data from devices, machines, and sensors in industrial environments.

Ultra low latency

With latency as low as 1 millisecond, 5G enables faster connectivity for IIoT technologies. Imagine the benefits of real-time monitoring of production lines, machines, and equipment.

Improve reliability and availability

Previous generations of wireless networks cannot guarantee seamless connectivity at all times. However, 5G supports stable connectivity even in remote industrial environments.

Enhance edge computing capabilities

5G can be combined with edge computing to facilitate data processing and analytics near or at the source, supporting real-time decision making for IIoT systems.

Connect multiple devices

This latest generation of wireless technology can simultaneously support up to 1 million connected IoT devices, sensors and robots, a critical capability to handle the technical complexity of Industry 4.0.

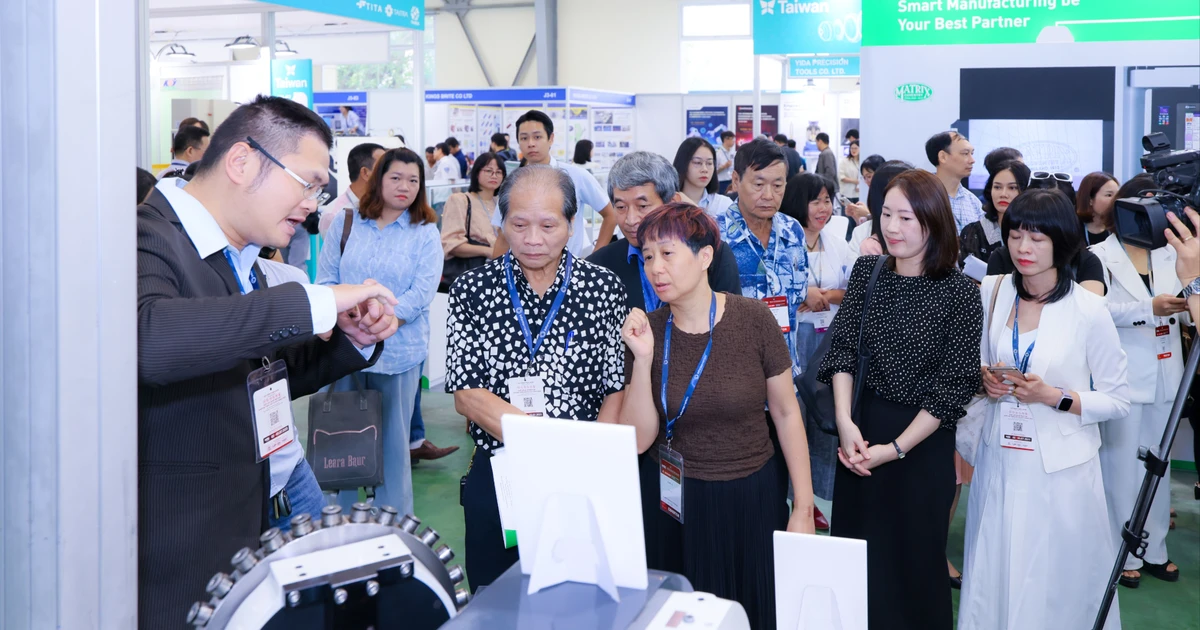

Industry 4.0 in practice

These combined benefits are opening up many new uses, including:

Smart warehouse

The high bandwidth of this network enables warehouse systems to support large-scale distributed networks with many connected devices and sensors to enhance inventory management and process optimization.

Additionally, 5G's ultra-low latency enables inventory tracking, machine control, robot operation, and other data-intensive tasks that require real-time processing and connectivity.

As a result, warehouse operators can increase productivity, reduce labor costs, and ensure more reliable connectivity for warehouse facilities.

Predictive maintenance

Another benefit of 5G is the ability to predict failures and proactively address equipment issues before they impact operations. Predictive maintenance helps keep machines running smoothly and prolong their lifespan. Additionally, manufacturers can continuously monitor the condition of machines to fine-tune them and ensure compliance with manufacturing standards.

Flexible manufacturing

5G enables increased flexibility in manufacturing processes. The development of this technology will help factories connect to the market - a key factor in allowing manufacturers to respond to changing demands or handle external logistics challenges effectively.

The ability to collect, analyze, and use real-time data is a key enabler of Industry 4.0. This business intelligence enables manufacturers to make real-time adjustments to address quality, efficiency, and safety issues, speed up production processes, and reduce costs.

Measurement issues

5G is a key enabler to realize the potential of Industry 4.0. However, these capabilities must be tested to ensure they operate as intended. This testing process requires the use of digital twins. Virtual models of these physical systems use data from sensors and other sources to create a simulation that can be used to test how a system operates under different conditions. This allows manufacturers to evaluate 5G infrastructure, validate use cases, and determine the best way to integrate the network.

Digital twins and 5G have supported the implementation of the 4.0 industrial revolution and when widely applied, the impact of these technologies will be multiplied many times.

5G technology will enable smart factories, enabling innovative manufacturing concepts that improve productivity and efficiency. As the industrial revolution accelerates, these and many other use cases will become a reality, with 5G capabilities being key to Industry 4.0.

(Source: EE Time Asia)

Source: https://vietnamnet.vn/5g-chia-khoa-di-toi-cong-nghiep-4-0-2331667.html

![[Photo] President Luong Cuong meets 100 typical examples of the Deeds of Kindness Program](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/ce8300edfa7e4afbb3d6da8f2172d580)

![[Photo] Many practical activities of the 9th Vietnam-China border defense friendship exchange](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/3016ed3ef51049219574230056ddb741)

![[Photo] President Luong Cuong receives Ethiopian Prime Minister Abiy Ahmed Ali](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/504685cac833417284c88a786739119c)

![[Photo] Opening of the Exhibition on Green Growth](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/253372a4bb6e4138b6f308bc5c63fd51)

![[Photo] Opening of the 4th Summit of the Partnership for Green Growth and the Global Goals](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/488550ff07ce4cd9b68a2a9572a6e035)

![[Photo] National Assembly Chairman Tran Thanh Man meets with Ethiopian Prime Minister Abiy Ahmed Ali](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/c196dbc1755d46e4ae7b506c5c15be55)

![[Photo] Vietnamese and Chinese students paint conical hats and make traditional ceramics](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/16/d3441e0b94a64e7596f7d31f6f8784b4)

Comment (0)