After a long period of difficulties in the consumer market, along with solutions to reposition products and markets, many businesses and industries have focused on investing in development in the direction of "greening" to improve competitiveness, reduce costs and increase value in the production chain, towards sustainable development.

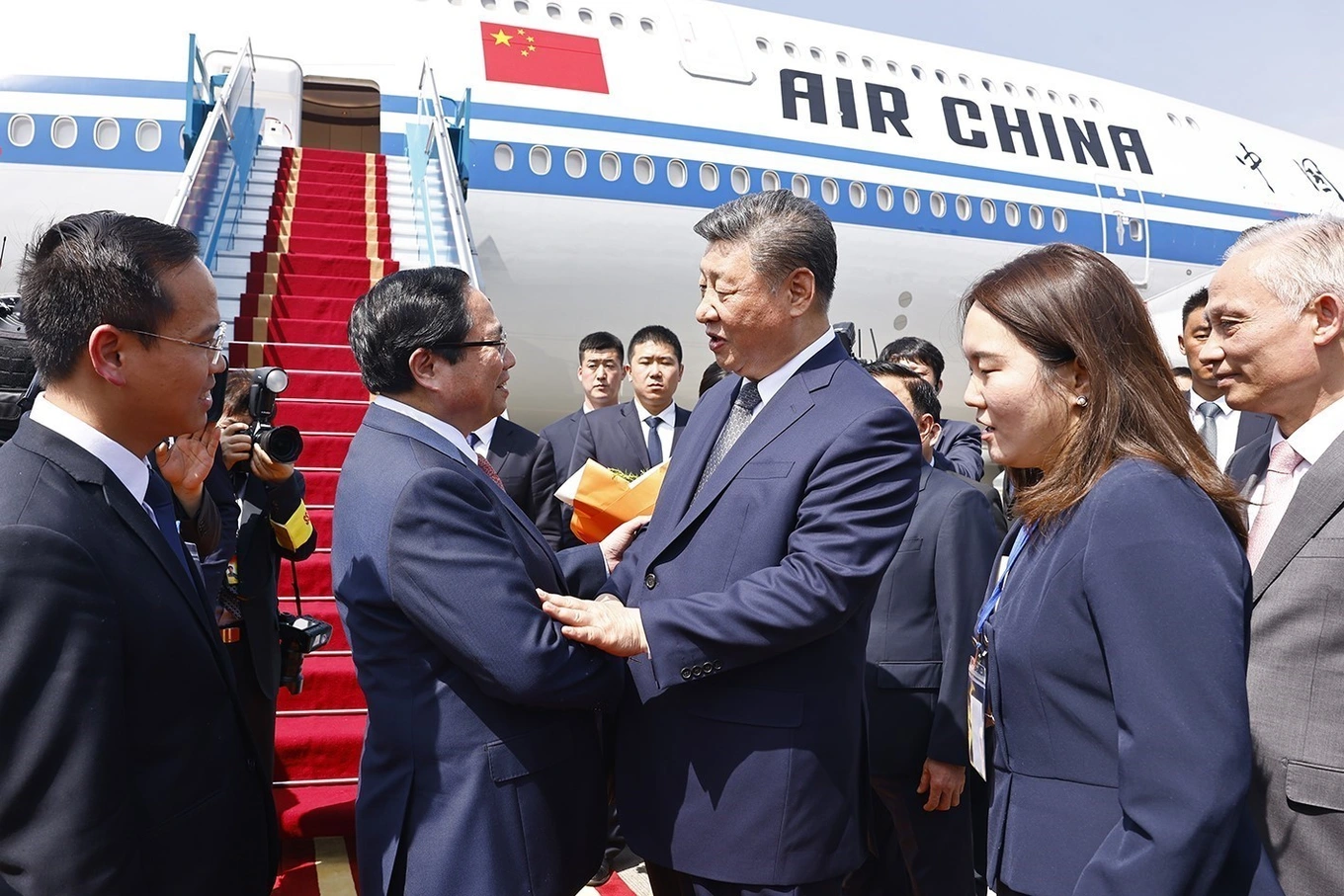

Producing garments for export at May 888 Company Limited (Quang Xuong).

Producing garments for export at May 888 Company Limited (Quang Xuong).

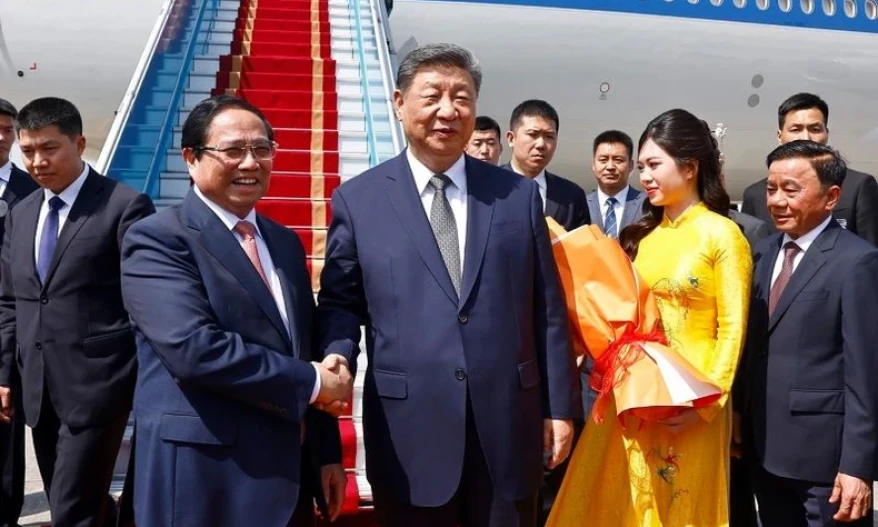

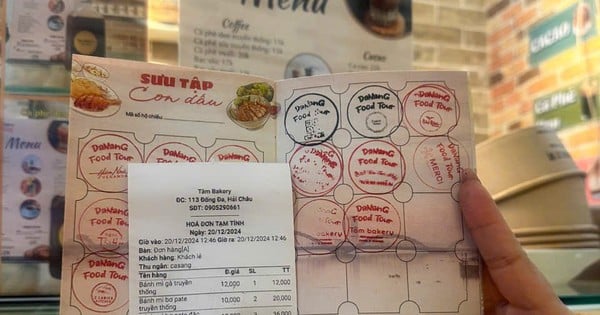

888 Garment Company Limited (Quang Xuong) has 2 factories with a scale of more than 1,100 workers. The company's main products are jackets, blazers and golf apparel for export, mainly exported to the US, EU and some Asian markets. Although facing many difficulties related to quantity and price of orders like other businesses in the industry, this company still maintains stable output and revenue, while expanding to some new markets in the last months of 2023 and early 2024. It is known that in addition to its brand and reputation in production, one of the advantages of this company is thanks to its "green" production standards that are always focused on. In addition to the rooftop solar power system that has been maintained for many years, the company has also invested in replacing electricity burning technology for scrap incinerators with traditional boiler technology to reduce emissions to the environment.

Le Van Bac, CEO of May 888 Company Limited, shared: “Each customer has different standards, but they are increasingly stricter from input materials, output products to the working environment of workers both inside and outside the factory area. In particular, customers in the European, American and Japanese markets always require some assessments such as building factories that meet the criteria of “green” factories and circular factories. We are continuing to invest in replacing the lighting system in each area for workers; at the same time, focusing on improving the working environment, the campus is increasingly green, clean and beautiful”.

According to the representative of Thanh Hoa Textile and Garment Association, “greening” and circular production are competitive criteria that major markets such as the US, EU, Japan, etc. always emphasize when surveying cooperation, in addition to factors such as price, product quality and delivery time. This requirement is to meet the standards of environmentally friendly output products, not harmful to human health, as well as ensuring production conditions for workers. Therefore, along with focusing on promoting self-sufficiency in raw material supply, utilizing and optimizing inputs through design, development and use of renewable fuels and materials, we are promoting efforts for businesses in the industry to promote clean production, produce more environmentally friendly products to improve competitiveness and sustainable development.

Paper and pulp production is also an industry that emits a lot of waste, with a high risk of environmental pollution due to the pulp soaking process. Recently, along with the guidance of functional sectors, a number of production facilities have focused on building wastewater treatment facilities that meet standards and have completed all documents and procedures according to legal regulations. Typically, at Hop Phat Forestry Processing Cooperative, Phu Nghiem Commune (Quan Hoa), the unit has invested in a 100% circular wastewater treatment system with a total cost of more than 7 billion VND. This treatment technology only uses a few typical chemicals such as alum and VAC, but can completely reuse wastewater.

Director of Hop Phat Forestry Processing Cooperative Nguyen Duy Chinh said: “The initial investment of the technology is quite large for a small cooperative. However, after a short time of operation, this technology has clearly demonstrated its effectiveness in terms of the environment and production circulation. In addition to saving costs on chemicals and operating labor, this technology also recovers about 10% of fine materials after the filtration process for re-production.”

It is known that some other enterprises in Quan Hoa district and mountainous districts have also proactively invested in items such as sludge presses, drying yards, closed-loop wastewater treatment systems; and sedimentation tanks before treatment to ensure compliance with legal regulations as well as help enterprises feel secure in production, improve operational efficiency and stabilize jobs for workers.

According to the Department of Industry and Trade, Vietnam has signed many new-generation free trade agreements. Along with agreements on consumption cooperation and tariff incentives, the agreements also set out many rules and commitments on “green” production, circular production associated with environmental protection and low emissions. In order not to be eliminated from the “game” by the high environmental and social standards set by import markets, businesses need to continue to change their thinking, proactively invest in technology and build a safe working environment for employees.

Article and photos: Tung Lam

Source

![[Photo] Air Force actively practices for the April 30th celebration](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/15/16fdec3e42734691954b853c00a7ce01)

![[Photo] Ho Chi Minh City after 50 years of national reunification through buildings and symbols](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/15/a224d0b8e489457f889bdb1eee7fa7b4)

![[Photo] General Secretary To Lam meets with veteran revolutionary cadres, meritorious people, and exemplary policy families](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/15/7363ba75eb3c4a9e8241b65163176f63)

![[Photo] Welcoming ceremony for Prime Minister of the Federal Democratic Republic of Ethiopia Abiy Ahmed Ali and his wife](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/15/77c08dcbe52c42e2ac01c322fe86e78b)

Comment (0)