The risks are forewarned

Even before the giant container ship crashed into the Francis Scott Key Bridge in Baltimore on March 26, sending a span of the bridge tumbling into the Patapsco River and disrupting cargo operations at a major U.S. port, there were reasons to worry about the troubles plaguing global supplies.

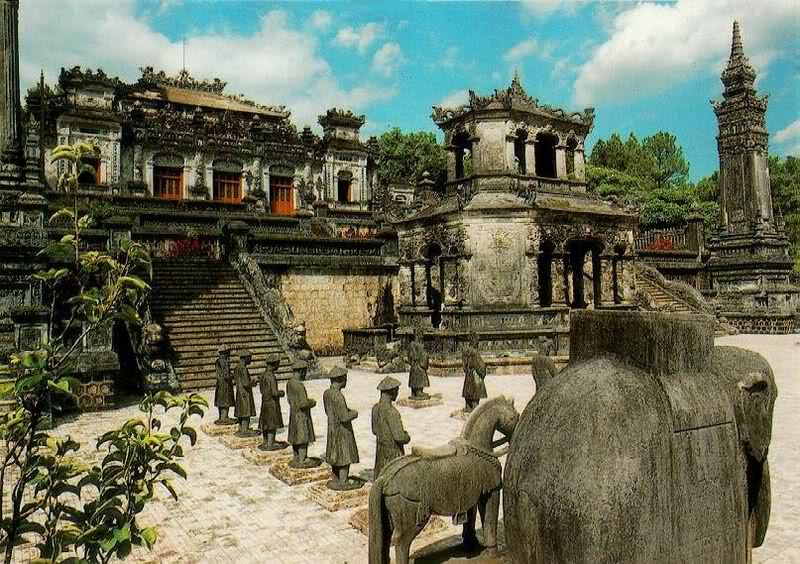

A container ship crashed into the Francis Scott Key Bridge in Baltimore, causing the more than 40-year-old bridge to collapse. Photo: NYT

Amid geopolitical headwinds, climate change and ongoing disruptions due to the pandemic, the risks of relying on ships to transport goods around the planet are clear.

The pitfalls of relying on factories around the world to supply everyday items like clothes and critical items like medical equipment have been clear and relentless.

Off the coast of Yemen, Houthi rebels fired missiles at container ships in what they said was a show of solidarity with Palestinians in the Gaza Strip.

That has forced shipping lines to largely bypass the Suez Canal, a vital waterway linking Asia to Europe, and instead sail around Africa — adding days and weeks to journeys and forcing ships to burn more fuel.

In Central America, scarce rainfall linked to climate change has restricted passage through the Panama Canal, which has blocked the vital link between the Atlantic and Pacific oceans, delaying shipments from Asia to the US East Coast.

The episodes come amid memories of another recent shock to trade: the closure of the Suez Canal three years ago, when the container ship Ever Given hit a curb in the waterway and became stuck.

While the ship was grounded and social media was flooded with memes about modern life being brought to a halt, traffic through the canal was shut down for six days, with the frozen trade causing an estimated $10 billion in losses per day.

Small faults still have big impacts

Now the world has gotten another visual summary of the fragility of globalization through the sudden and shocking removal of a major bridge in a major industrial city with bustling ports in the United States.

The Ever Given supership blocking the Suez Canal in 2021. Photo: AFP

The Port of Baltimore is smaller than the largest container terminals in the US — those in Southern California, Newark, New Jersey and Savannah — but it is a key part of the vehicle supply chain, serving as a landing zone for cars and trucks coming from factories in Europe and Asia. It is also a major entry point for US coal exports.

Many of those goods may be delayed in reaching their final destination, forcing shippers to make alternative plans and limit inventory. In an interconnected world, problems at one point can quickly be felt more widely.

“The collapse of the Francis Scott Key Bridge will put pressure on other modes of transportation and port alternatives,” said Jason Eversole, CEO of FourKites, a supply chain consulting firm. Some cargo that would have gone through Baltimore will likely end up in Charleston, Norfolk or Savannah.

That would increase demand for trucking and rail services, while making it more complicated and expensive to get goods where they need to go.

“Even if they clear the debris from the water, traffic in the area will be affected as truck drivers become reluctant to move goods in and out of the area unless prices increase,” Mr Eversole said.

Anxiety is now pervading the supply chain, a topic that is no longer just a matter for trade professionals but also a topic of conversation for people trying to understand why they can't complete their kitchen renovations.

Fragile global supply chains

Fresh memories of the alarming shortage of protective medical equipment during the first wave of COVID-19, which left doctors in some of the wealthiest countries without masks or gowns to care for patients, and households remember being unable to order hand sanitizer and scrambling for toilet paper, a previously unimaginable prospect.

Many of the worst effects of major supply chain disruptions have been significantly lessened or have disappeared. The cost of shipping a container of goods from a factory in China to a warehouse in the United States skyrocketed from about $2,500 before the pandemic to more than 10 times that during the turmoil. Now that price has returned to historical norms.

Container ships are no longer lining up at ports like Los Angeles and Long Beach, California, as they once did as Americans flooded the system with orders for exercise bikes and barbecues during quarantine.

But many products remain scarce, in part because the industry has long practiced just-in-time manufacturing: Instead of paying to stock more goods, companies have for decades cut back on inventory to save costs.

They have relied on container shipping and global trade networks to get what they need, leaving the world vulnerable to any sudden disruptions in the movement of goods.

Container ships waiting to dock at the Port of Los Angeles are congested in 2021, as the COVID-19 pandemic continues to rage. Photo: NYT

In rapidly growing US cities, the housing shortage that has sent home prices soaring continues as contractors remain unable to secure items like electrical switches and water meters, which can take more than a year to arrive.

“The supply chain is still holding up construction,” said Jan Ellingson, a real estate broker at Keller Williams in Casa Grande, Arizona.

Phil Levy, former chief economist at the shipping logistics company Flexport, says it would be a mistake to infer from wayward container ships that globalization itself is wrong.

“Why don’t we do everything in one place so we don’t have to worry about shipping?” he said. “Because that would be significantly more expensive. We save a huge amount of money by allowing companies to source components where they are cheapest.”

But companies are increasingly looking to limit their exposure to shipping vulnerabilities and shifting geopolitics. Walmart has shifted manufacturing of industrial goods from China to Mexico.

Other US retailers like Columbia Sportswear are looking for factories in Central America, while Western European companies are focusing on moving production closer to customers, expanding factories in Eastern Europe and Türkiye.

Given these tectonic shifts, the disaster in Baltimore could be a temporary disruption to the movement of goods or a long-term challenge. With supply chains, the consequences of any single disruption can be difficult to predict.

A factory near Philadelphia might have hundreds of ingredients needed to make paint, but a single delayed ingredient—perhaps stuck on a container ship off the coast of California, or a shortage due to weather-related shutdowns at a Gulf of Mexico plant—could be enough to shut down production.

The lack of a single critical component — a computer chip or the part that assembles it — could force automakers from South Korea to the American Midwest to freeze finished cars in parking lots, waiting for the missing part.

Somewhere on earth — maybe in the United States, and maybe across the ocean — someone is waiting for a container stuck on a ship docked in the port of Baltimore.

And that wait may become more familiar, given the fragile state of global trade flows today.

Nguyen Khanh

Source

![[Photo] Prime Minister Pham Minh Chinh chairs conference to review the implementation of Resolution No. 18-NQ/TW](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/dcdb99e706e9448fb3fe81fec9cde410)

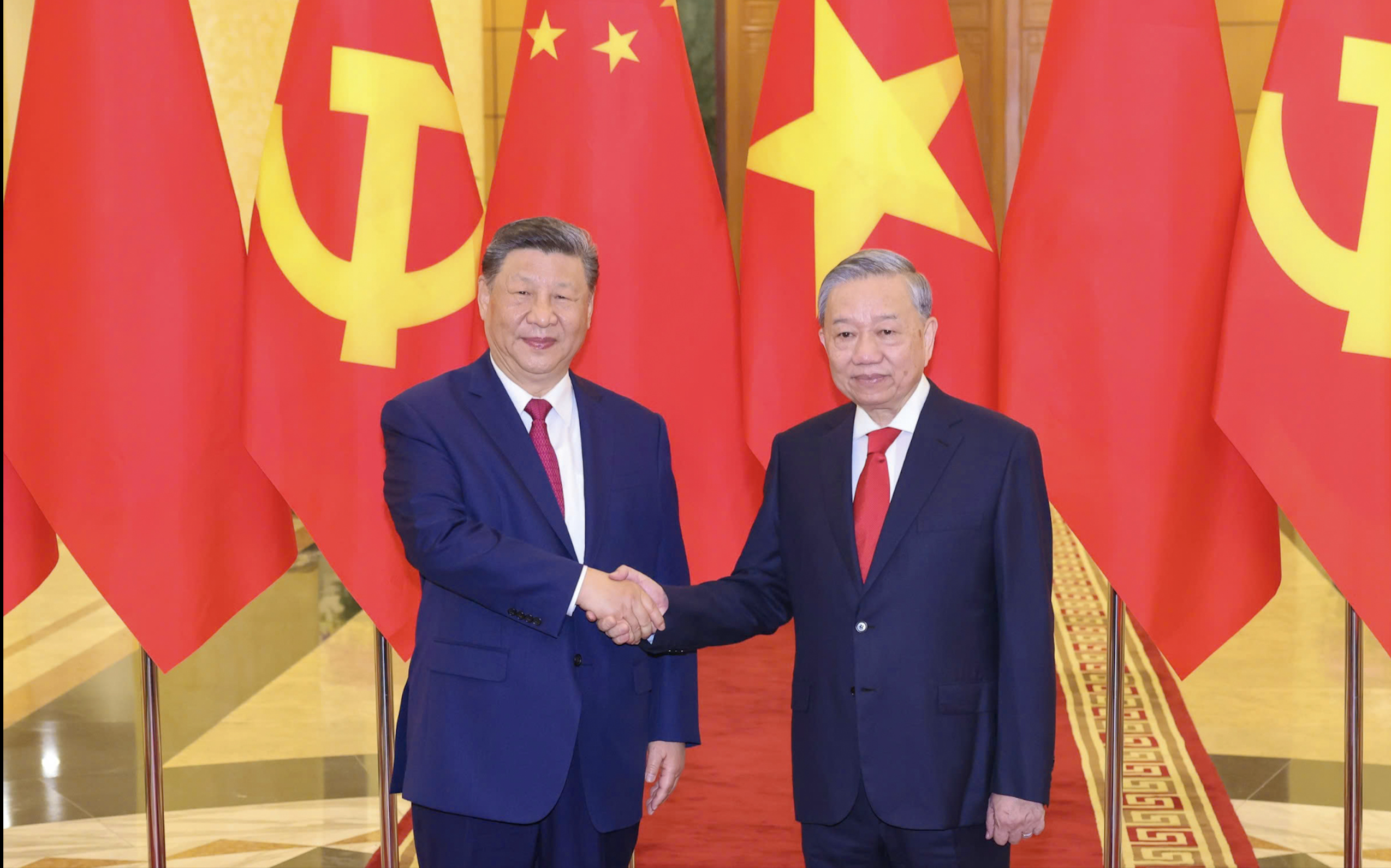

![[Photo] General Secretary To Lam holds talks with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/b3d07714dc6b4831833b48e0385d75c1)

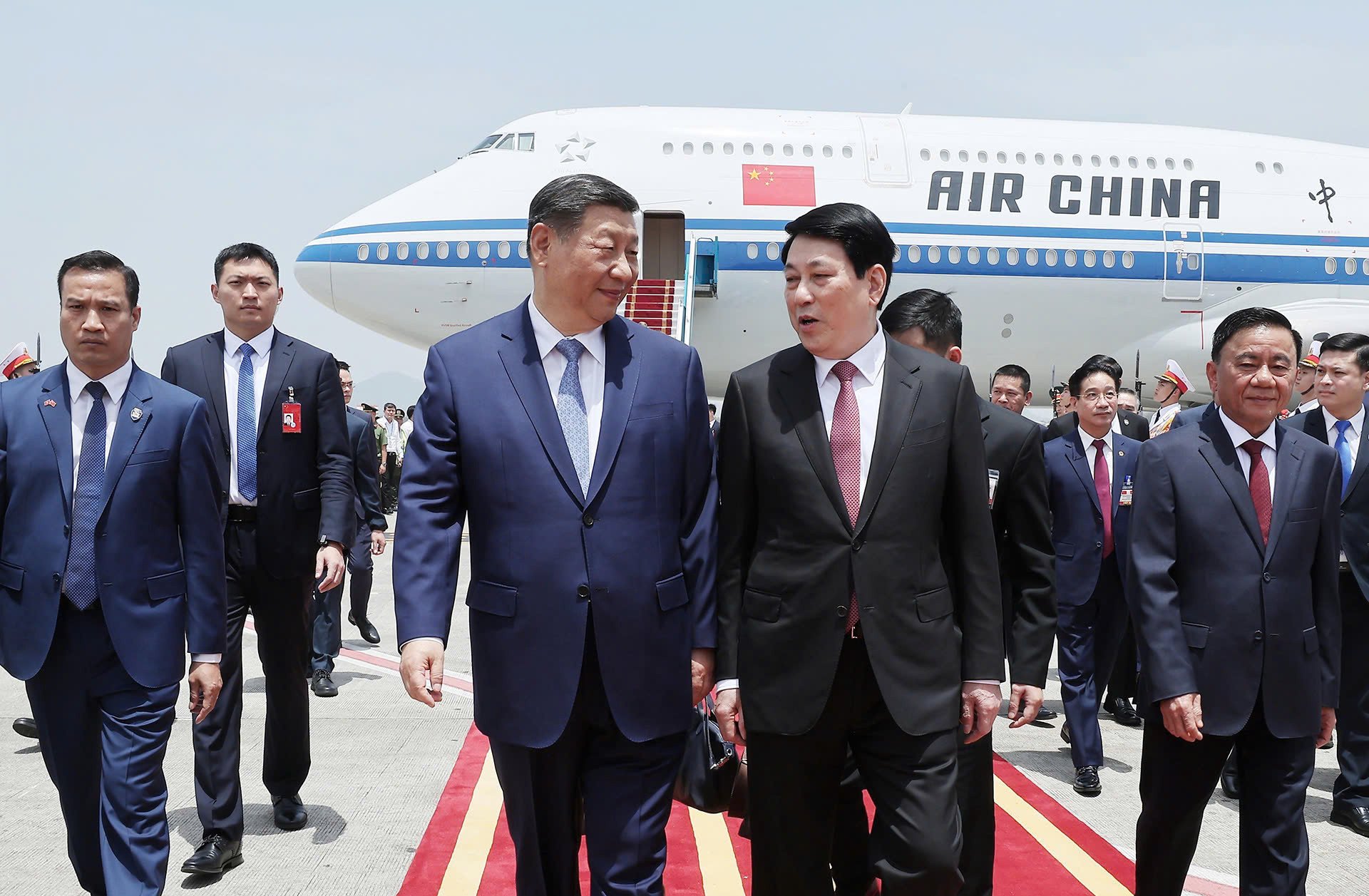

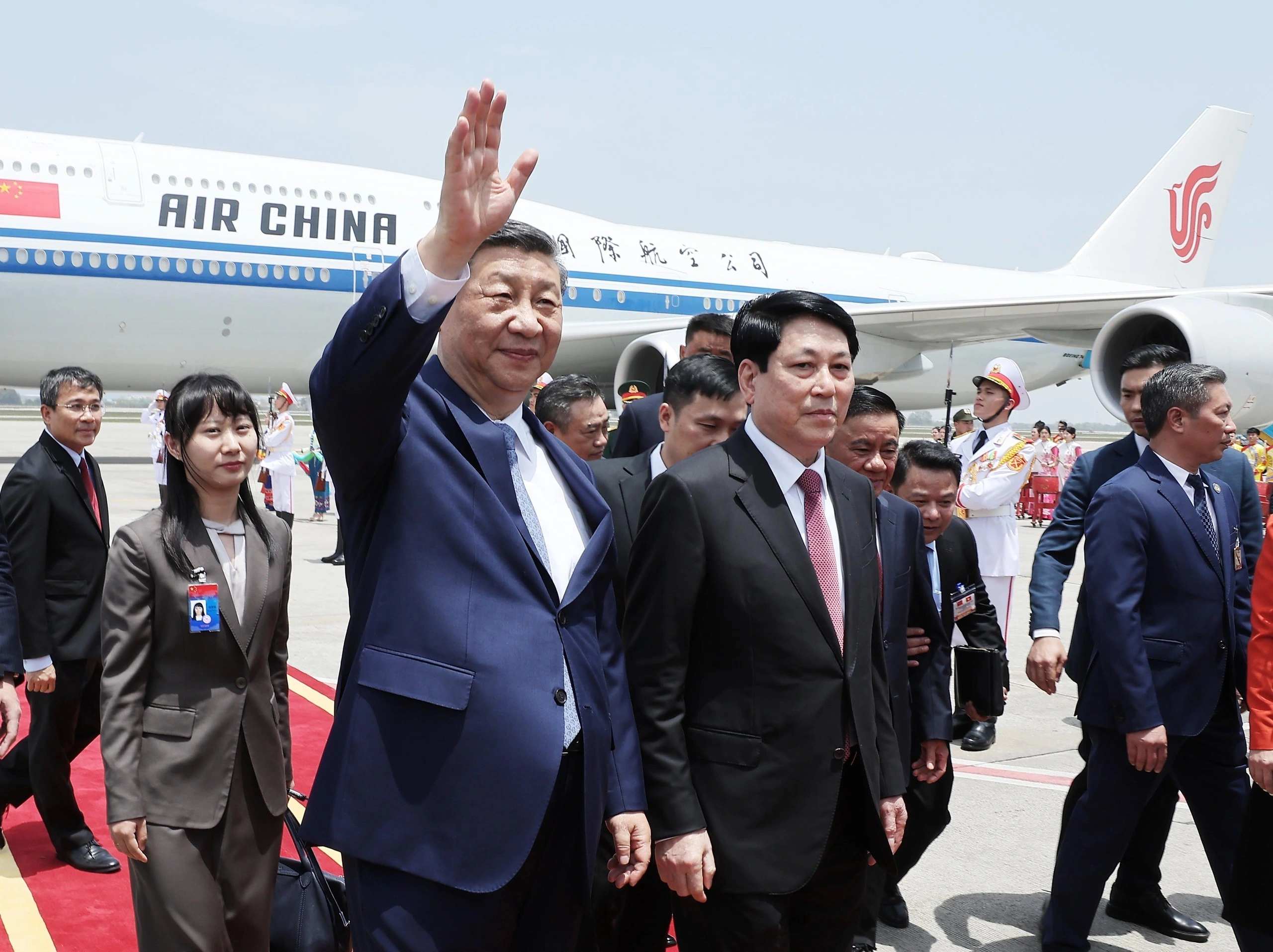

![[Photo] Ceremony to welcome General Secretary and President of China Xi Jinping on State visit to Vietnam](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/5318f8c5aa8540d28a5a65b0a1f70959)

Comment (0)