Faced with global challenges and domestic market demands, the textile and garment industry needs to fundamentally change from supply chain to technology, from human resources to production processes.

Sustainable development orientation

“Greening” production is an inevitable requirement for all businesses, and the textile and garment industry is no exception to this trend. Currently, the transition to sustainable production is spreading strongly in the industry, including small and medium-sized enterprises. However, the rapid development of the textile and garment industry is now facing the need for comprehensive innovation to increase value and achieve long-term sustainability.

At the conference “Hanoi and the Northern provinces – Promoting investment in green production transformation, sustainable development in the digital economy” organized by the Hanoi Center for Promotion, Investment and Tourism, Mr. Truong Van Cam, Vice President and General Secretary of the Vietnam Textile and Apparel Association (VITAS) shared about the goals in the development strategy of the Vietnamese textile and garment industry to 2030 and vision to 2035.

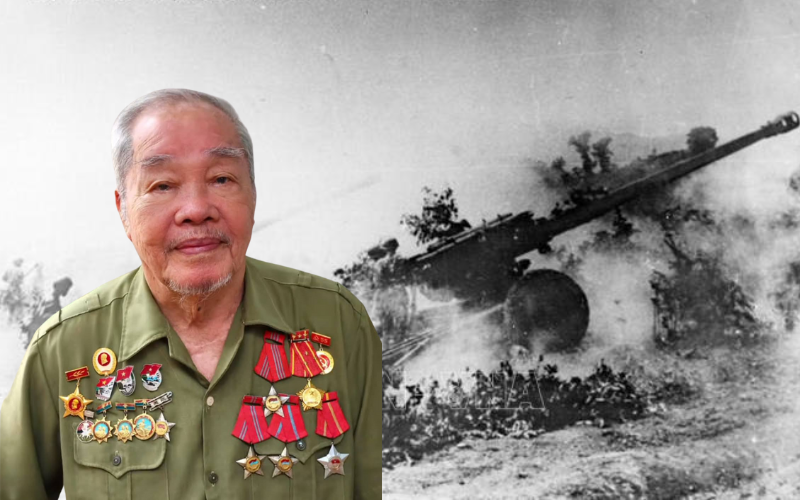

|

| Mr. Truong Van Cam, Vice President and General Secretary of the Vietnam Textile and Apparel Association (VITA). Photo: Nguyen Linh |

According to Decision 1643/QD-TTg, the textile and garment industry aims to increase export turnover from 6.8% to 7.2% per year in the period of 2021 - 2030, and from 7.5% - 8% for the period of 2021 - 2025. "With the target of achieving export turnover of 50 - 52 billion USD by 2025 and up to 68 - 70 billion USD by 2030, the textile and garment industry needs to not only increase production but also invest heavily in the value chain," Mr. Cam said.

In particular, the domestic value ratio in the textile and garment industry is also expected to increase from 51-55% in the period 2021-2025, and from 56-60% in the period 2026-2030. This requires the industry to focus on optimizing domestic supply, developing modern production networks, and improving management capacity.

To achieve these goals, the Government has set out the direction for developing a circular economy and optimizing the domestic value chain, aiming to build a Vietnamese textile and garment brand with high quality and competitiveness in both domestic and international markets.

In addition, “greening” and sustainable development are also competitive requirements that major markets such as the United States, the EU, and Japan require of suppliers. Garment products exported to Europe must now meet the requirements of being produced from cotton, polyester fibers mixed with recycled fibers made from natural materials, waste or surplus textile products.

These standards are not only about price and quality but also include sustainability indicators such as ESG (environmental, social and governance) and LEED (energy and environmental design) standards. Suppliers who meet these requirements will have a competitive advantage and attract more orders.

The development orientation from now until 2030 of the textile and garment industry is to gradually shift from rapid development to sustainable development. This is an important shift, requiring synchronization from production, business, technology to consumption, in order to minimize environmental impacts and enhance the competitiveness of the domestic supply chain.

With a vision to 2035, the Vietnamese textile and garment industry focuses on sustainable development, promoting the circular economic model, perfecting the domestic supply chain and especially building national brands that reach international standards.

Conquering demanding markets with quality

Mr. Truong Van Cam said that currently, major markets such as Europe and the US have strict requirements for textile products. Typically, the European Union has launched a "Sustainable Textile" strategy that requires products to be durable, reusable, and contain a certain amount of recycled content. At the same time, businesses must be transparent about information about the origin and production process to meet international quality standards.

For the US market, the Uyghur Forced Labor Prevention Act has imposed strict requirements on the supply chain, forcing Vietnamese businesses to clearly identify the origin of raw materials and meet human rights and environmental protection standards. These laws require major changes from textile and garment businesses, from supply chain management processes to improving production technology.

Domestically, Vietnam’s commitment roadmap at COP26 on the Net Zero target by 2050 has posed many challenges for the textile and garment industry. To meet these requirements, the industry needs to invest heavily in dyeing and weaving technology, digital transformation and green growth. In addition, self-sufficiency in input materials is also necessary to take advantage of tariff incentives from the Free Trade Agreements (FTAs) that Vietnam has signed.

To adapt to these requirements, the Vietnamese textile and garment industry has been investing in solutions such as wastewater treatment, waste recycling and emission reduction. Many businesses have now applied energy-saving solutions, switching from using coal and oil to more environmentally friendly energy sources such as electricity and biomass to reduce their impact on the environment.

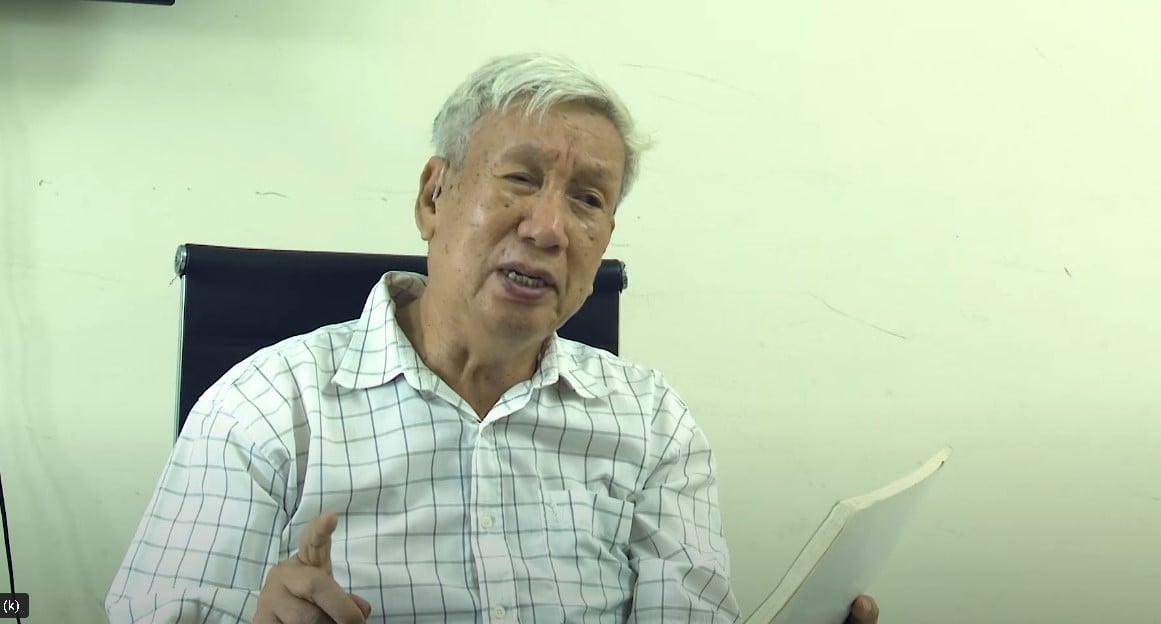

|

| The government needs to work with textile and garment enterprises to build a "greening strategy". |

In particular, using environmentally friendly and traditional materials such as silk, jute, hemp, banana, pineapple, bamboo. This trend not only meets market demand but also helps promote the local value of the textile industry. In addition, linking businesses in the same area to collect and treat wastewater, waste or install rooftop solar power systems also contributes to creating a greener and more sustainable production environment.

In the past three years, Garment 10 Corporation has implemented many green production activities such as investing in modern machinery and equipment that use less electricity; investing in solar energy systems, rooftop solar panels; linking production chains in Vietnam and abroad to make the most use of recycled products, from nature, etc.

Mr. Than Duc Viet, General Director of May 10 Corporation, shared: “Greening production is no longer a matter of choice but has now become a mandatory requirement for businesses to move towards sustainable exports. Even in the production process, coal-fired input fuels are being converted to biomass-fired fuels to ensure the lowest carbon emissions. It is expected that in 2024, if the entire May 10 project comes into operation, it will help reduce more than 20,000 tons of carbon emissions into the environment.”

Similarly, TNG Thai Nguyen and LGG Bac Giang are also pioneers in the transformation to sustainable production. In particular, the working environment, highly trained human resources and modern machinery and equipment are the top priorities that these enterprises aim for. The result of the transformation process is a cool, clean campus that helps workers feel secure at work.

Along with that, the modern machinery system is capable of meeting high requirements for environmental protection in production, minimizing raw material costs and production costs. For example, with TNG Thai Nguyen, on sunny days, the solar panels can provide 100% of the factory's electricity, on average reaching about 70 - 80% of electricity consumption needs.

The General Secretary of the Vietnam Textile and Apparel Association believes that from now until 2030, the textile and garment industry will gradually shift from a focus on rapid development to a focus on sustainable development and circular business. “The government must work with businesses to build a “greening strategy”, investing in factories with infrastructure that meets the evaluation standards of brands such as working environment, wastewater, emissions, renewable energy with rooftop solar power…”, Mr. Cam frankly said.

Source: https://baodautu.vn/doanh-nghiep-det-may-voi-cuoc-dua-xanh-hoa-d228546.html

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to discuss tax solutions for Vietnam's import and export goods](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/19b9ed81ca2940b79fb8a0b9ccef539a)

![[Photo] Summary of parade practice in preparation for the April 30th celebration](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/78cfee0f2cc045b387ff1a4362b5950f)

![[Photo] Phuc Tho mulberry season – Sweet fruit from green agriculture](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/1710a51d63c84a5a92de1b9b4caaf3e5)

Comment (0)