Quang Tri is known for many famous craft villages and each region has its own unique characteristics. My Chanh ginger jam, Dai An Khe banh chung, Dai An Khe banh tet, Trieu Trung banh giay, Mai Xa banh hoc are all branded products that delight people, especially during Tet holiday...

Quang Tri is known for many famous craft villages and each region has its own unique characteristics. My Chanh ginger jam, Dai An Khe banh chung, Dai An Khe banh tet, Trieu Trung banh giay, Mai Xa banh hoc are all branded products that delight people, especially during Tet holiday...

On the days before the Lunar New Year of At Ty - 2025, coming to My Chanh village, Hai Chanh commune, Hai Lang district, we can feel the spicy flavor of traditional ginger jam spreading everywhere. The profession of making ginger jam in My Chanh village has existed since ancient times, closely associated with dozens of households here. This profession not only brings high income at the end of the year for the people but also preserves the traditional beauty of the homeland.

My Chanh ginger jam has a spicy, natural aroma, unlike industrially produced ginger jam. In My Chanh, this profession is often considered a sideline, because it is only made within the first 20-25 days of December each year. During Tet, each family making jam also earns a net profit of 7-10 million VND. In particular, there are households making up to ten tons of jam, after deducting costs and labor costs, they also earn a profit of over 40 million VND.

Thanks to the ginger jam making profession, families here have a prosperous Tet holiday. This year, in My Chanh village, there are about 20 households making ginger jam, with a total output of over 100 tons of finished jam, the revenue from this profession is about 6 billion VND. My Chanh ginger jam has a brand name, so it is favored by customers in and outside the province during Tet.

To produce finished ginger jam, My Chanh people have to work hard to process it. “The first step is to choose the ingredients, then wash the ginger, slice it thinly, boil the pre-processed ginger over hot coals, then coat it with sugar, dry it, and package the finished product,” said Ms. Vo Thi Tam, owner of a ginger jam production facility in My Chanh village, Hai Chanh commune, Hai Lang district.

No matter how busy My Chanh people are, at the end of the year they still arrange time to choose ingredients and make some ginger jam to offer to their ancestors, give as gifts to relatives, sell in the market and more importantly, preserve the traditional profession of their hometown.

Dai An Khe village, Hai Thuong commune, Hai Lang district has a traditional profession of making Chung cake and Tet moon cake with dozens of households producing and trading. Making Chung cake and Tet moon cake takes place all year round but is busiest during Tet holiday when orders are 3-4 times more than usual.

Chairman of Hai Thuong Commune People's Committee Tran Van Kinh said: "During the Lunar New Year of At Ty - 2025, households producing banh chung and banh tet in Dai An Khe village used about 256 tons of sticky rice, supplying the market with about 320,000 banh chung and banh tet with an estimated revenue of about 11.5 - 12 billion VND. Banh chung and banh tet are not only consumed in the village, commune, and district but also supplied to all provinces and cities nationwide."

According to many elders and owners of Chung cake and Tet cake making establishments in Dai An Khe village, to make a delicious cake, the preparation of ingredients must be very thoughtful and thorough, combined with the experience and skills of the person wrapping and cooking the cake. In Dai An Khe, almost every family knows how to make Chung cake and Tet moon cake. And this generation passes it down to the next generation, so the traditional craft of the village is increasingly developing.

To make Chung cake and Tet moon cake, you have to choose good sticky rice, clean it, soak it, then mix it with the water of the previously blended spinach. In addition, when customers have a need, the baker can mix white sticky rice with gac fruit water to create orange or red cakes or use charcoal sticky rice to wrap the cake to create a beautiful purple cake. The cake filling is made of pork belly and green beans marinated with fragrant spices. And the cake is wrapped in banana leaves and cooked on a wood stove or electric stove for about 6 - 7 hours.

Banh chung is square, banh tet is crescent-shaped and when two crescent-shaped slices are stacked together, they form a beautiful circle, so they are often called banh tet moon. The most impressive thing about banh chung and banh tet moon Dai An Khe is that the cakes have beautiful green, orange, red, and purple colors, the cake filling is yellow from mung beans, mixed with pork belly, purple onions, and ground black pepper.

The harmony of colors and flavors makes Dai An Khe's Chung cake and Tet moon cake famous and captivates the hearts of those who enjoy them, especially during Tet.

Dao Trung village, Trieu Trung commune, Trieu Phong district is a village with a long tradition of making rice cakes. Perhaps since the village was founded, rice cakes have followed the pioneers to this land.

“I don’t know when banh giay was invented, but since I had a topknot of hair, I have seen my mother make it for death anniversaries or traditional Tet. My husband and I have been involved in this traditional profession for a long time and until now, not only my family but also many households in the village still maintain the method, steps, and way of making banh giay, so the ancient flavor has not faded at all,” said Mr. Nguyen Huu Cu, owner of a banh giay production facility in Dao Trung village, Trieu Trung commune, Trieu Phong district.

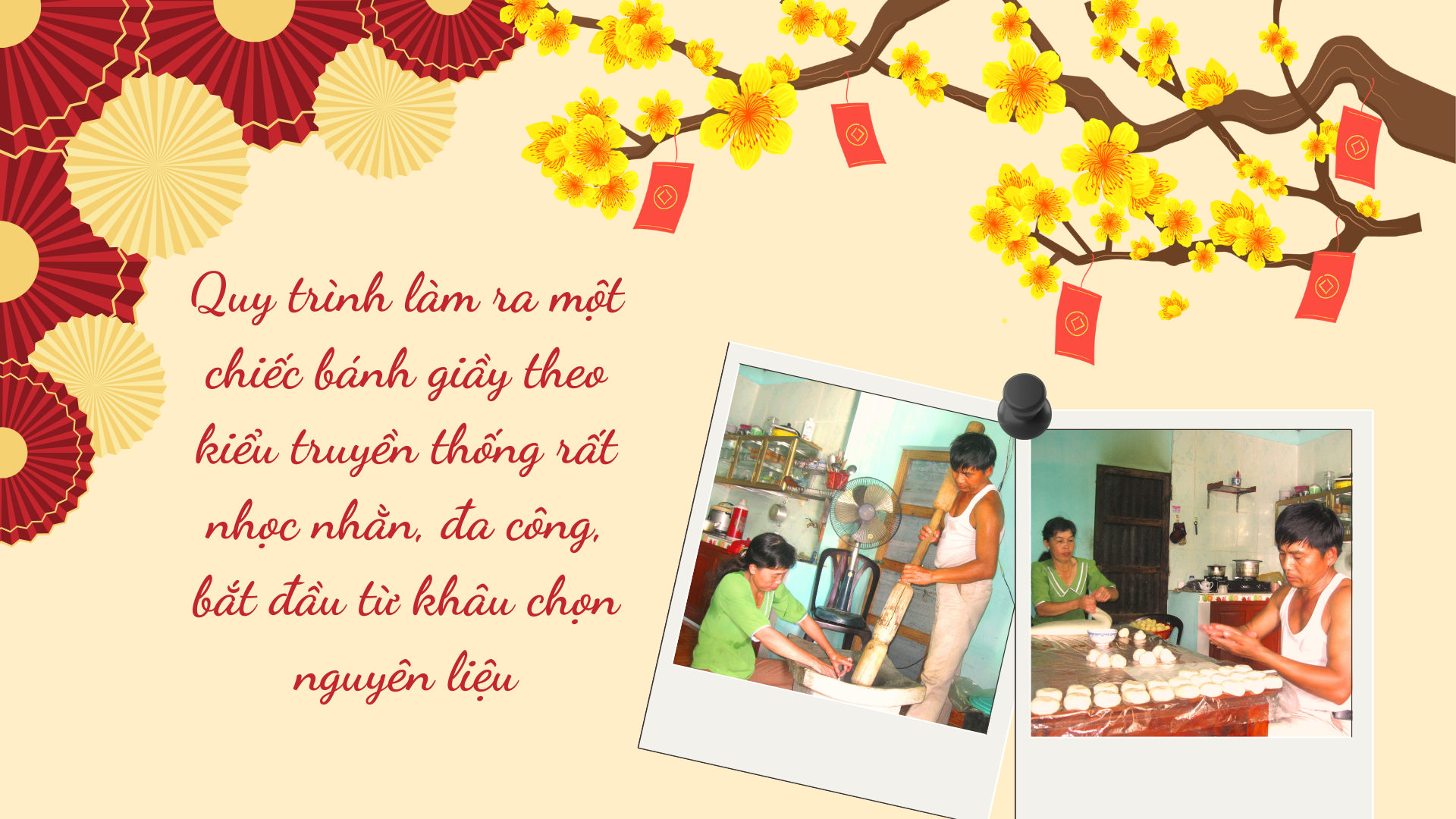

According to ancient folk beliefs, banh chung symbolizes the earth, banh giay symbolizes the sky, to pray for warmth, peace, and harmony with heaven and earth. The process of making a banh giay in the traditional way is very hard and requires many tasks, starting from the stage of choosing the ingredients.

Locals here say that sticky rice must be carefully sifted to remove bad grains, sand or mixed rice if any, then soaked in well water that has been filtered through an osmosis tank. The sticky rice must be soaked for 6-7 hours before being scooped out to drain and then made into sticky rice. When the sticky rice is cooked, it is poured into a stone mortar and pounded immediately with a wooden pestle. While the pounder is raising the pestle, the other person must dip both hands into boiling water to smooth the sticky rice that is stuck to the pestle. After 30 minutes, a batch of sticky rice will turn into a very smooth dough.

Rubbing her red hands from repeatedly dipping them in boiling water, Ms. Nguyen Thi Hoa, owner of a rice cake production facility, explained: “You have to dip your hands in boiling water to make it easier to smooth the sticky rice that is stuck to the pestle and to prevent the dough from becoming soggy. If you use cold water, not only will you not be able to smooth the sticky rice off the pestle, but it will also ruin the dough. That is why the person who smooths the dough must frequently change the boiling water during the process of pounding the sticky rice.”

Next is the filling, the mung beans are cleaned with boiling water then stewed until cooked, pounded until smooth, seasoned according to customer's request and finally rolled into small balls by hand.

Next, the baker must wash his hands with lime water to disinfect and avoid sticking when rolling the cake, and absolutely do not use soap or regular hand sanitizer. During the process of making the cake, the people here do not use daily cooking oil to roll the cake, but use peanut oil. Because according to their explanation, only this type of oil does not stick to the hands and gives the cake a beautiful color.

Thanks to the meticulous preparation and traditional experience, Dao Trung village's sticky rice cakes always create a distinct brand compared to other cakes on the market. "Consumers will feel the softness of sticky rice, the fatty aroma of peanut oil and the sweet taste of green beans mixed in each cake.

The flavor is completely different from the cake made from raw glutinous rice, kneaded with boiling water to form the cake and then steamed. Another difference is that traditional sticky rice cake is soft and flexible after being stored for a long time, retaining its flavor and color, while cakes from other places will quickly dry out, become hard and change color," Ms. Hoa added.

At the end of the year, when farm work and orders have thinned out, people in Dao Trung village are busy buying more ingredients to make rice cakes to offer to their ancestors during the Tet holiday.

In the days leading up to the Lunar New Year, dozens of households in Mai Xa village, Gio Mai commune, Gio Linh district are busy making traditional banh hoc to deliver to customers in and outside the province. Although the banh hoc here is rustic and handmade, it has a special flavor that makes people far from home and diners linger even after just one taste.

Almost all banh hoc is only made seasonally during Tet. Right from the beginning of December, many households here have started preparing ingredients and tools to make cakes according to orders.

“This year, my family started making them from the first week of December and plans to supply the market with about 400 banh hoc cakes according to orders. Each banh hoc cake usually weighs from 1 to 1.2 kg with the price at the facility ranging from 120,000 to 150,000 VND/cake. Making banh hoc cakes does not make much profit, but it is an additional source of income during Tet and moreover, it helps preserve the traditional profession passed down from our ancestors,” said Ms. Tran Thi Ly, who has many years of experience making banh hoc cakes in Mai Xa village, Gio Mai commune.

To make Banh Hoc, people here roast sticky rice with hot sand until it just pops, then sift it many times to clean the sand, separating the popped grains from the husks. Next, cook a mixture of sugar water and fresh ginger. When the mixture is as thick as desired, you can add roasted, shelled peanuts or keep the peanuts separate when making the cake.

When all the ingredients are ready, the baker will put the previously cooked mixture of sticky rice, roasted peanuts, sugar water, and ginger into a rectangular wooden cake mold. Then, use a specialized cake-making tool to press and compress the mixture to create the desired adhesion. After removing the cake from the mold, it is covered with a layer of sticky rice flour on the outside and left to dry for a few hours before eating.

Currently, the whole village has about 10 families making banh hoc, supplying thousands of cakes to the Tet market. Through many changes, Mai Xa banh hoc still retains its unmistakable old flavor. On a spring day, enjoying a cup of tea with family and friends, enjoying a piece of Mai Xa banh hoc is truly poetic and cozy...

Nhon Bon - Truc Phuong (PERFORMANCE)

Source: https://baoquangtri.vn/e-magazine-lang-nghe-truyen-thong-vao-xuan-191370.htm

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to discuss tax solutions for Vietnam's import and export goods](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/19b9ed81ca2940b79fb8a0b9ccef539a)

![[Photo] Unique folk games at Chuong Village Festival](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/cff805a06fdd443b9474c017f98075a4)

Comment (0)