The disruption of global supply chains during the pandemic has left many manufacturers struggling. From this crisis, LG sees an opportunity to expand its Smart Factory model.

Many global companies still rely on manufacturing facilities in countries with low labor costs. In return, when force majeure occurs, the supply chain is broken, the damage is huge. The impact of the Covid-19 pandemic has highlighted the weaknesses of the traditional production model.

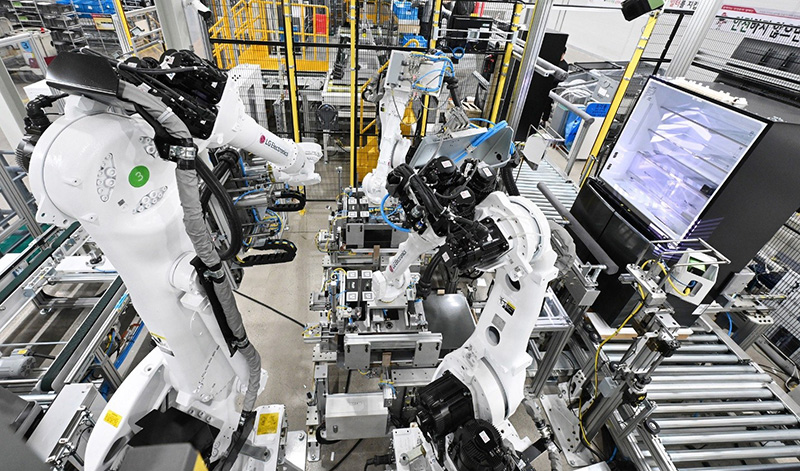

|

| LG Electronics' smart factory at LG Smart Park in Changwon, South Korea. |

Seeing the opportunity in this B2B business segment, LG Group quickly packaged the smart factory solutions they have applied in the electronics manufacturing sector for many years and provided them to global partners. Precedence Research's report shows that the potential of this market is about 268 billion USD by 2030.

Recently launched, LG’s Smart Factory division has received attention from customers in the battery, auto parts and logistics sectors. Key projects that this enterprise is implementing include factories for Hyundai, GE Healthcare, Hanmi Pharm, etc.

|

| Robots integrated with AI make the production process faster and safer. |

The advantage of the Korean electronics company is its 70 years of experience in building and operating 60 high-tech factories worldwide. The company is holding 770 TB of production materials and 1,000 related patents. The company also increases the application of AI and digital transformation in management to limit the presence of humans in the process, reduce errors and impacts from force majeure.

LG applies many industrial and automated robotic solutions in the production process. In addition to the types of robotic arms that work in programming mode, the company provides autonomous mobile robot solutions with cameras and LiDAR sensors to detect obstacles. The most advanced type of equipment is the Mobile Manipulator system, consisting of an arm with many interconnected joints, performing a series of seamless tasks.

|

| Inside LG's smart factory in Changwon. |

The manufacturer also offers comprehensive software solutions for designing, locating machines in factories, monitoring operations, and detecting failures. LG's automated factories in Changwon, South Korea, and Tennessee, USA, have been recognized as LightHouse Factories by the World Economic Forum. After implementing the new solutions, productivity at the Changwon facility increased by 17%, energy efficiency improved by 30%, and error costs decreased by 70%.

In Vietnam, the Smart Factory model is also applied by LG to the OLED panel production line at the LG factory in Hai Phong.

Smart Factory is part of LG's plan to transform into a Smart Living Solution Provider by 2030. One of the three pillars of development that the company has chosen is to shape its brand in the B2B manufacturing sector.

In fact, LG has been an important partner in the global technology and automobile supply chain for many years. However, the outstanding success of the electronics and home appliances segment has made this business segment less noticeable. Through this plan, the Korean company wants to increase its presence in new manufacturing areas, becoming a partner providing advanced solutions to global partners.

Source: https://baodautu.vn/lg-tim-thay-mo-vang-moi-sau-dai-dich-d227482.html

![[Photo] Unique folk games at Chuong Village Festival](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/cff805a06fdd443b9474c017f98075a4)

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to discuss tax solutions for Vietnam's import and export goods](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/19b9ed81ca2940b79fb8a0b9ccef539a)

Comment (0)