To continue to attract and retain miners, coal industry units have regularly invested in means and equipment to transport people from industrial sites to production locations in the mines. Thanks to travel support, workers are guaranteed health, increase useful time in production shifts, contributing to increasing productivity and coal output for the unit.

Currently, in both mining areas of Canh Ga Well and Vang Danh Well, Vang Danh Coal Joint Stock Company - Vinacomin has transported workers to the mine using specialized means of transport such as: Cable winch, crane. These means help workers save time, especially reduce human effort in the process of moving from the mine door to the production locations.

For example, with the double-wheeled carriage, Vang Danh Coal is using the double-wheeled carriage that can transport 18 people at a time per trip. The carriage has 6 rows of seats, each with 3 seats, and the doors are designed on both sides to facilitate workers getting on and off the carriage. With this vehicle, workers will be transported from the mine entrance to the workplace. The walking time is guaranteed to be shortened to just under 300m depending on the location.

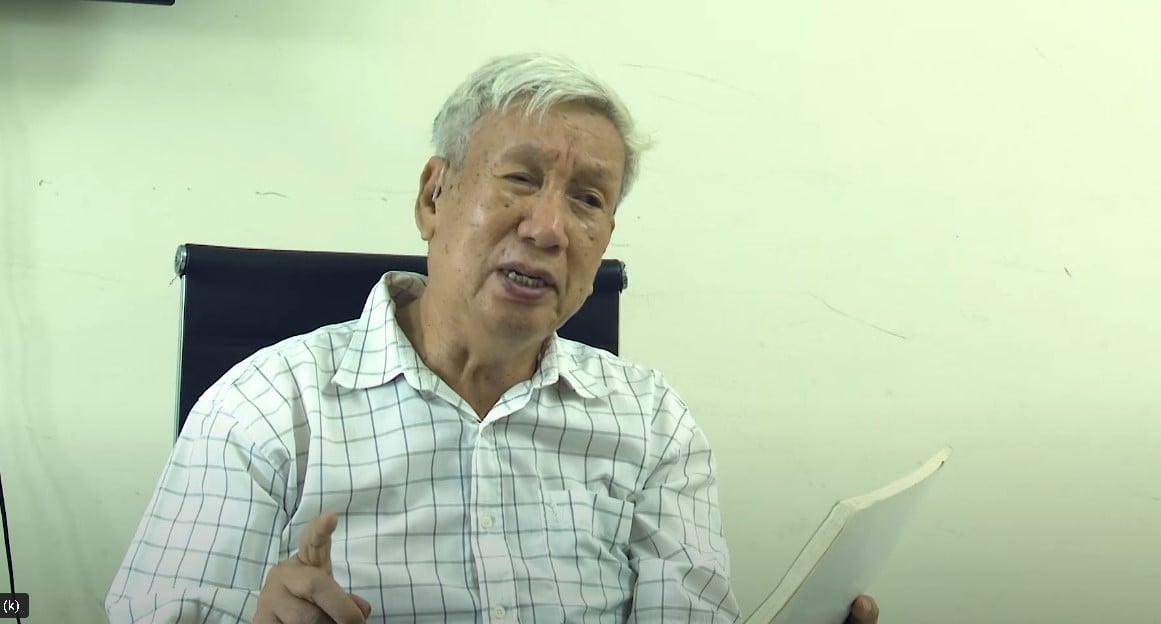

"Instead of walking kilometers and spending hours to get to work like before, now it only takes us miners a maximum of 20 minutes to get to the production site. The time and effort previously spent on commuting, we now spend on resting, relaxing and focusing on improving labor productivity" - miner Le Van Hop, Workshop K1, Vang Danh Coal Joint Stock Company shared.

Vang Danh Coal currently has over 4,000 workers and miners working in two main production areas, Gieng Canh Ga and Gieng Vang Danh. The production area is getting deeper and farther away, revealing many difficulties in production. To ensure the task of exploiting over 3.5 million tons of raw coal/year, Vang Danh Coal determined that it will need to invest more in transportation, especially transporting people from the surface to the production location under the mine.

According to Mr. Trinh Viet Bao, Deputy Head of the Mechanical and Electrical - Transportation Department, in the coming time, the Company will install and put into use 2 intermediate-level cable car winch systems from level +0 to level -70 in area I, from level -10 to -70 in area II; establish and implement a project to improve the capacity of transporting people through Vang Danh well to reduce the number of operating trips, reduce waiting time for workers at the well gates, thereby shortening travel time for workers and contributing to increasing productivity and coal output for the unit.

At Nam Mau Coal Company - TKV, currently, the transportation work from level +125 into the mine is carried out by the unit in 3 main directions, including: through-seam mine at level +125, main inclined shaft and auxiliary inclined shaft. For the transportation of people, Nam Mau Coal Company is maintaining 2 forms: electric train - passenger car and cable car. In which, the largest transport capacity of the cable car is 360 people. This cable car system was put into use by the company since the end of 2016 and has been effective until now.

The installation and application of the cable car people transport system comes from practical needs because when the Nam Mau Coal well mining project comes into operation, there are often 450 people working in a production shift and when fully exploited at -50 level, there will be 600-650 people/shift.

When mining deep underground, the task of transporting workers to the work location is always a difficult problem for underground mines. How to ensure that workers do not lose their labor when moving to the mining locations at the beginning of the shift or moving to the surface smoothly at the end of the shift is always the concern and goal of mines. Therefore, in recent years, TKV has paid special attention and resolutely directed units to increase the application of technical advances in the work of transporting people, improving the traveling conditions for miners to the best extent.

Regarding the work of transporting people, up to now, the whole Group has had 150 systems of transporting people of all kinds, including: Cage system in vertical shafts; single-end load shaft system combined with passenger carriages in inclined shafts; endless cable winch system; monorail system with diesel and electric traction; endless cable car system for transporting people and winch system to support pedestrians...

It can be affirmed that the transportation work in the mine, especially the transportation of people of TKV has made many breakthroughs compared to the previous period. However, the Group's leaders still direct the underground units to increase the application of transportation technology suitable for each unit, not allowing workers to walk to the workplace more than 500m or carry materials and equipment more than 30m. This is also one of the effective solutions to retain miners in the context of many difficulties in recruiting underground human resources.

Source

![[Photo] Opening of the 11th Conference of the 13th Party Central Committee](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/f9e717b67de343d7b687cb419c0829a2)

![[Photo] April Festival in Can Tho City](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/bf5ae82870e648fabfbcc93a25b481ea)

![[Photo] Unique folk games at Chuong Village Festival](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/cff805a06fdd443b9474c017f98075a4)

Comment (0)