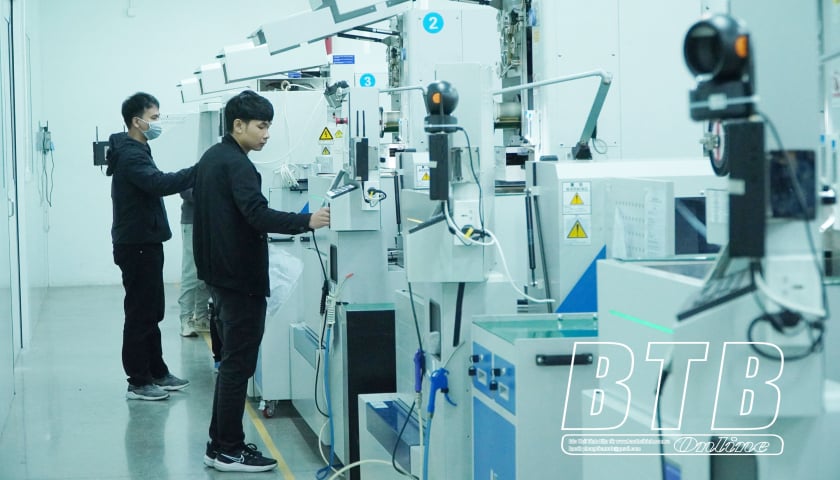

Long Hau Ceramics Joint Stock Company invests in automatic robots to produce household ceramic products.

As the cradle and foundation for the Thai Binh ceramic industry, in its development journey, Long Hau Ceramics Joint Stock Company always clearly identifies the importance of applying science and technology to production. In particular, in the past 5 years, the Company has made a breakthrough in investment and innovation of production lines, from using manual coal kilns to modern gas kilns, from semi-mechanized to automated production processes.

Mr. Nguyen Quoc Phong, Deputy Director of the Company said: In 2024, we will invest nearly 110 billion VND to convert and modernize the kiln system, environmental drying system, kaolin grinding machine, extrusion machine, high-pressure seamless casting system and civil porcelain forming system. Up to now, Long Hau's production lines are capable of automating stages such as product shaping, enamel spraying, pattern printing, and firing. Thanks to that, productivity has increased 4 times compared to before the technology conversion, while reducing the rate of defective and damaged products, ensuring consistent product quality.

Long Hau Ceramics Joint Stock Company is a pioneer in applying the energy management system according to ISO 50001:2018 and the quality management system according to ISO 9001:2015. The smart production management system allows businesses to monitor and manage the entire production process from input materials to output products, helping to optimize the process, reduce costs, improve product quality, and improve the working environment for workers. In particular, the application of new technology and smart management systems helps Long Hau create products with diverse designs, sophisticated designs, greening the factory, meeting the increasing demands of the market.

If Long Hau previously focused only on developing the domestic market, in the past 10 years the Company has determined its goal of reaching out to the international market. The Company's solution is to invest in technology and automation to standardize criteria for manufacturing plants, improve competitiveness, and meet the strict standards of foreign markets. In particular, the design and market development teams are facilitated and encouraged to research and create new products to meet the increasing needs of customers. Thanks to that, international partners and customers who come to visit and inspect the factory's capacity and other standards on labor, environment, and social security of the Company all highly appreciate and accept to sign cooperation agreements on production and product supply. Currently, Long Hau's sanitary and household ceramic products have been exported to many countries around the world such as Japan, Korea, the United States, Italy and some other European countries. In 2023, the Company's export turnover will reach nearly 600,000 USD, in 2024 it will reach nearly 1 million USD, and the target is to reach 1.5 million USD in 2025.

Thanks to new advanced machinery and technology, labor productivity increases and working conditions for workers improve.

In addition to investing in technology and machinery, Long Hau Ceramics Joint Stock Company also focuses on improving the quality of human resources. The company regularly organizes training courses, updates knowledge and professional skills, and invests in staff and workers to participate in training courses to improve their professional qualifications. The company builds a professional, friendly and dynamic working environment so that workers can maximize their creativity, dedication, and increase labor productivity. Ms. Phan Thi Yen, a worker at a household ceramic factory, shared: The skills of workers are constantly being improved and supported by machinery and technology, so labor productivity increases, which means income also increases to meet the needs of life. Working conditions are increasingly improved, welfare regimes are taken care of, everyone is excited and confident in sticking with the business for a long time.

In the current context of the domestic market still facing difficulties, Long Hau Ceramics Joint Stock Company considers export as the only way to create room for development. To follow this path, Long Hau continues to identify investment in technology and automation as key and decisive factors. Mr. Bui Van Son, Chairman of the Board of Directors and Director of the Company affirmed: Investing in technology to improve competitiveness is the key to integrating products into the world market, developing sustainably, striving to achieve the goal of making Long Hau one of the leading enterprises in the Vietnamese ceramic industry.

Khac Duan

Source: https://baothaibinh.com.vn/tin-tuc/4/221040/chia-khoa-mo-cua-xuat-khau

![[Photo] April Festival in Can Tho City](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/bf5ae82870e648fabfbcc93a25b481ea)

![[Photo] Opening of the 11th Conference of the 13th Party Central Committee](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/f9e717b67de343d7b687cb419c0829a2)

![[Photo] Unique folk games at Chuong Village Festival](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/cff805a06fdd443b9474c017f98075a4)

![[Photo] Prime Minister Pham Minh Chinh commends forces supporting Myanmar in overcoming earthquake consequences](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/e844656d18bd433f913182fbc2f35ec2)

Comment (0)