Europe could be left behind in the battery manufacturing race due to unforeseen US competition and rising raw material costs.

The audit report titled "Need for a new strategic impetus" by the European Court of Auditors (ECA) has just concluded that "the EU risks falling behind in its efforts to become a global battery powerhouse".

Annemie Turtelboom, who led the audit, said that without action, Europe risks being forced to postpone its ban on internal combustion engine vehicles beyond 2035, or continue to implement it and rely heavily on China, which produces 76% of global batteries.

“The EU must not become as dependent on batteries as it is on natural gas,” he said. According to the study’s authors, this is not just a matter of economic sovereignty.

The EU saw the risk of relying on batteries from outside the bloc as early as 2008. So in 2017, they planned to create a battery alliance. By 2018, the action plan was defined. Since then, the European Commission has been implementing it, and projects are springing up across Europe. They even worried about battery overproduction.

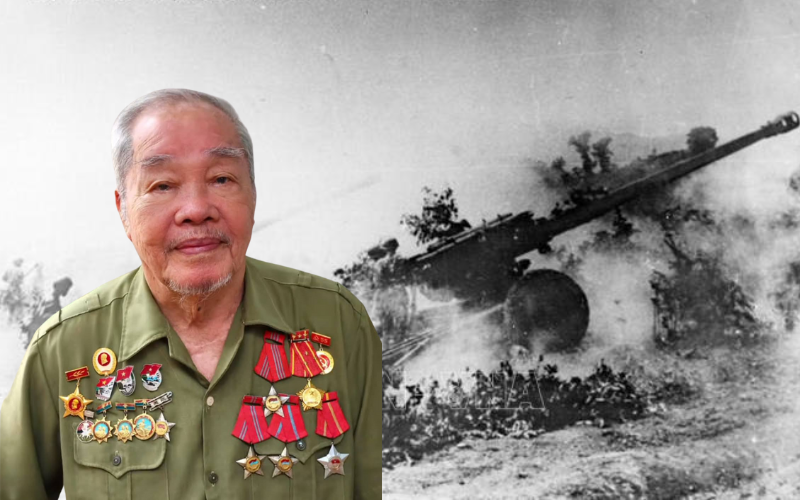

An electric vehicle battery factory under construction in Douvrin, France on February 13, 2023. Photo: REA

The report also points out that the EU’s battery production capacity is growing rapidly, with the potential to increase from 44 GWh in 2020 to 1,200 GWh by 2030. This is enough to meet demand from 2025 and equip 16 million vehicles per year by 2030 – more than the pre-Covid-19 record number of vehicles registered in the bloc.

But all this is just “if”. Auditors are very skeptical about the actual implementation of the announced projects and point to a series of major obstacles.

The first is the complexity of subsidies. They are considered difficult to interpret and the waiting time is too long. But this is still the easiest challenge to solve. The second is the speed at which the world is changing, and Europe has been slow to adapt. The entire EU battery action plan was drawn up at a time when energy was affordable and did not take into account the risks that could increase.

However, energy tariffs have increased by 60% in the first half of 2022, hurting some projects, and there is no financial backstop for this. Meanwhile, other countries are moving fast. The US Inflation Reduction Act (IRA), passed in August 2022, subsidizes “Made in USA” batteries at $45 per kWh and 10% of the cost of producing critical minerals and materials. So far, the EU has provided €1.7 billion in subsidies, plus €6 billion from countries through the Important Projects of Common European Interest (IPCEI) programs.

Third, the main challenge raised by the European Court of Auditors is access to raw materials, although this has become a priority for the Commission this year. Despite ongoing negotiations and the signing of strategic partnerships with several countries, the EU still lacks free trade agreements with the largest global producers of raw or refined materials for batteries, notably China (raw natural graphite, natural graphite, refined cobalt, lithium, nickel), the Democratic Republic of Congo (raw cobalt) and Australia (raw lithium).

The EU also lacks a clear vision of its needs. The European Commission’s assessment of critical raw materials – updated this year – is still incomplete for demand for raw cobalt, raw lithium, refined natural graphite and does not include the production of processed materials (anodes and cathodes), according to the report.

The prices of all these raw materials are rising sharply, combined with rising energy prices, creating a real concern. At the end of 2020, the estimated cost of a battery pack produced in Europe was double the cost of a low-cost electric car. The ECA wonders how the battery industry can compete. This is a real question for EU battery industry policy.

Phien An ( according to Le Monde )

Source link

![[Photo] Looking back at the impressive moments of the Vietnamese rescue team in Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/5623ca902a934e19b604c718265249d0)

![[Photo] "Beauties" participate in the parade rehearsal at Bien Hoa airport](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/155502af3384431e918de0e2e585d13a)

![[Photo] Summary of parade practice in preparation for the April 30th celebration](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/11/78cfee0f2cc045b387ff1a4362b5950f)

Comment (0)