According to data from the General Statistics Office, in the first two months of 2024, the textile and garment group achieved 5.2 billion USD in exports, an increase of 15% over the same period last year, ranking 4th in the group of products with the highest turnover in the country.

Experts say that this result is due to the world textile and garment consumer market gradually warming up from the end of 2023. The domestic textile and garment business community is also actively "managing" to find orders; at the same time, this industry is also gradually adapting to the requirements of the import market, which is greening production.

According to Mr. Than Duc Viet, General Director of May 10 Corporation, greening in production is no longer a matter of wanting or not, but has now become a mandatory requirement. The gradual adaptation of Vietnamese enterprises will help export goods sustainably. May 10 has implemented the "greening" of production for about 3 years, through specific actions such as investing in modern machinery and equipment, using less electricity, or investing heavily in solar energy systems, rooftop solar panels, linking production chains in Vietnam and abroad to use the most recycled and natural products to ensure the proportion of fiber materials in the composition of the product according to customer requirements. Even in the production process, coal-fired input fuels are being converted to biomass-fired fuels to ensure that carbon emissions are minimized. It is expected that in 2024, if the entire May10 project comes into operation, it will help reduce more than 20 thousand tons of carbon emissions into the environment.

Many major global brands in the textile industry have announced their roadmaps for using recycled, natural and circular products in their development from now until 2050. Buyers, especially large brands and international business chains, are restructuring their global supply chains to ensure strict sustainability targets. These requirements emphasize issues such as environmental efficiency, using recycled materials, seeking organic or sustainable materials, reducing energy consumption and conserving non-renewable resources such as fossil fuels and water. This pressure from consumers will be the driving force for brands to commit and take action to improve sustainability throughout their supply chains.

In Europe, there is also a Green Deal (EGD) with targets set from now until 2030 and a vision for 2050; including a separate agreement on sustainable textile development with many requirements on recycled materials and product longevity. It is expected that in 2024, the EU will also introduce Ecodesign regulations in the textile industry to limit textile waste and food waste in Fark to fork. These regulations require manufacturers and exporters to prepare and convert production accordingly.

Professor Dr. Andreas Stoffers, Country Director of the Friedrich Naumann Foundation (FNF) in Vietnam, said that for Vietnam's textiles, the EU has been and is the leading important export market. However, for the EU, textiles are among the top industries that cause environmental degradation and climate change. Therefore, textiles are also among the groups that focus the most green efforts of the EU. Most of the EU's green policies on textiles are focused on the circular and sustainable textile strategy with policy directions on eco-design to ensure durability, repairability, recyclability, enhancing information through digital passports of products, information requirements to combat green fraud, minimizing the release of microplastics from textile products into the environment, minimizing toxic chemicals in fibers and applying extended producer responsibility...

Compared to many other industries and sectors, the standards applied to the textile industry are considered more complex, challenging and significant, covering all textile products and being legislated as minimum legal requirements, mandatory implementation, not just recommendations. In addition, the standards, measures and regulations of the EU Green Deal affect many stages in the production chain, from design to raw materials, from production, farming to transportation, from use to repair, from disposal to recycling... and not only applied to the final product.

Despite the challenges, if we strictly comply with and implement greening standards in the manufacturing industry, we will be able to proactively, synchronously and comprehensively transition to green production. This is a great opportunity for businesses and also the best way for businesses to be one step ahead, accessing the EU's potential green product market early with a rapidly growing customer base of green-conscious consumers in this region. At the same time, early adaptation to green requirements in the EU also provides a certain guarantee for businesses' ability to export to other developed markets such as the United States, the United Kingdom, Japan, Australia, etc.

From a research perspective, economist Dinh Trong Thinh said that the process of greening production and reducing carbon emissions has received more attention from businesses. Although the changes are not much, the transformation is clear. This has created favorable conditions for Vietnamese goods to access demanding markets.

However, the reality is that meeting green standards in the textile industry requires huge conversion costs and a very long conversion time. While most of Vietnam's textile and garment exporting enterprises are small and medium-sized, converting internal control systems and greenhouse gas inventories requires faster and less costly conversion.

"Therefore, in addition to the efforts of enterprises, it is necessary to have the support of the Government, ministries, branches and localities in creating a policy corridor to encourage investors to move towards "green production"; in which, mainly credit policies with more preferential interest rates and limits for enterprises investing and producing green products. This is also a specific step of Vietnam to achieve the commitment of "zero carbon" by 2050", economic expert Dinh Trong Thinh recommended.

According to VNA

Source

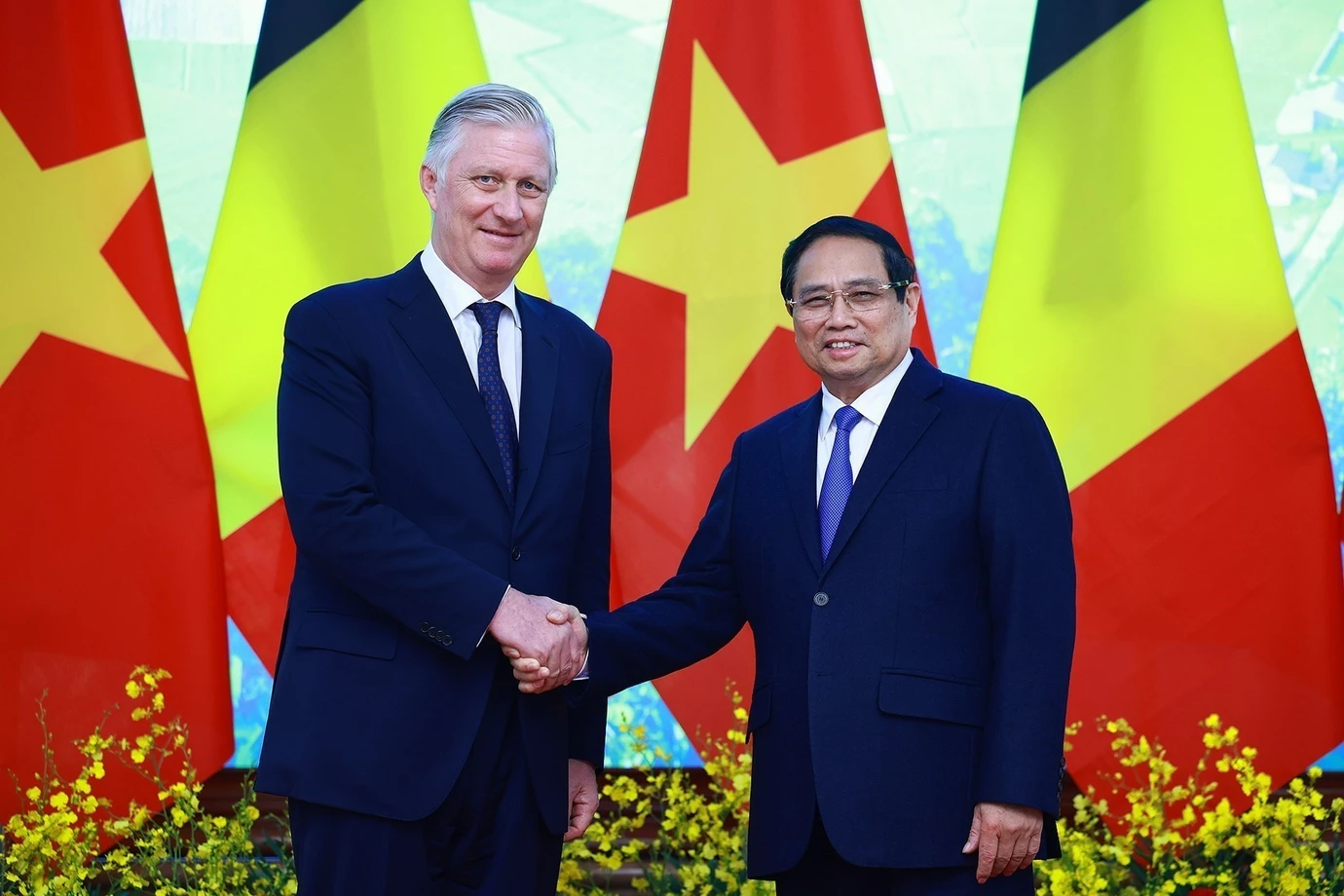

![[Photo] Prime Minister Pham Minh Chinh meets with King Philippe of Belgium](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/be2f9ad3b17843b9b8f8dee6f2d227e7)

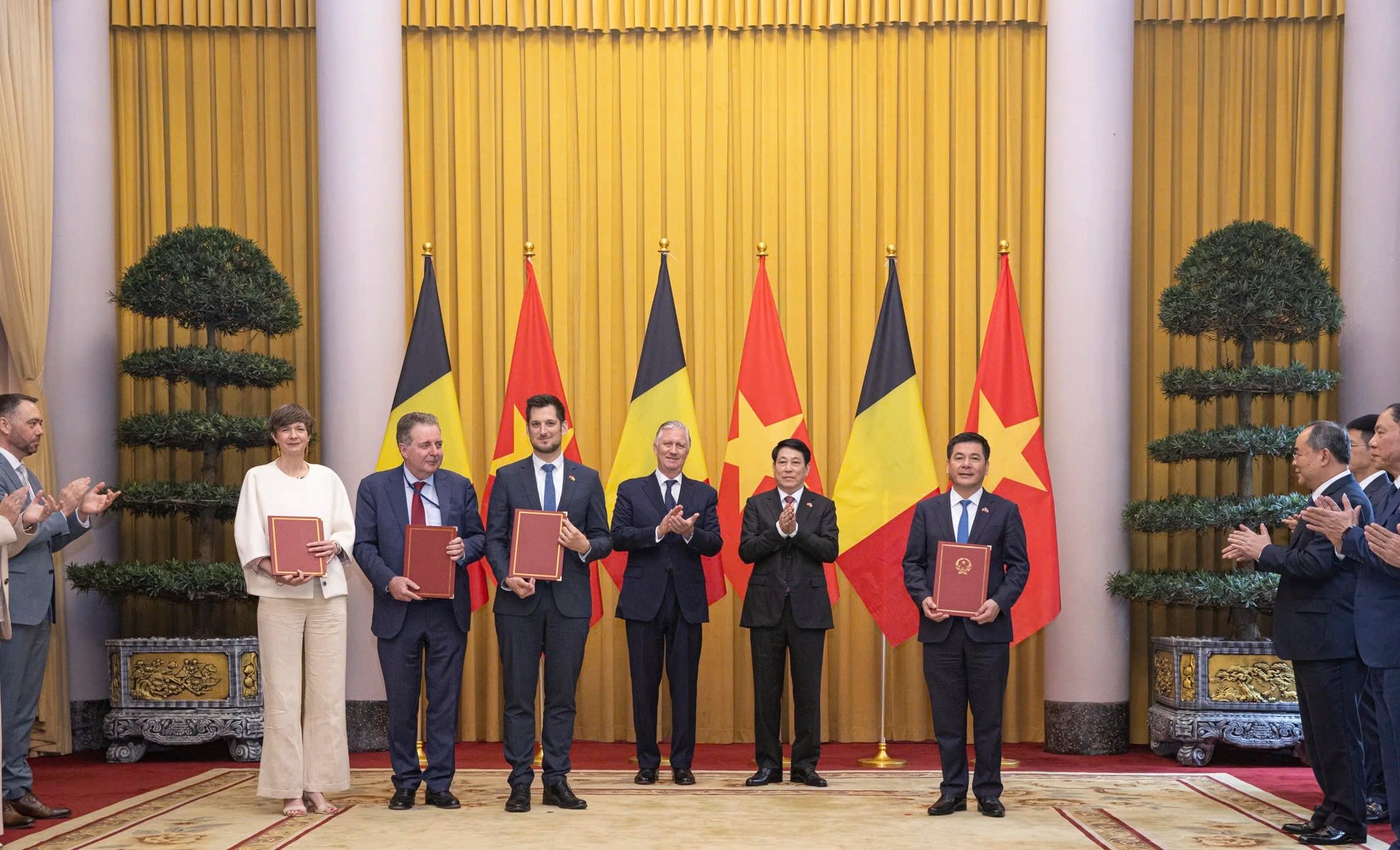

![[Photo] General Secretary To Lam receives King Philippe of Belgium](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/e5963137a0c9428dabb93bdb34b86d7c)

![[Photo] Close-up of Vietnam's sniffer dog team searching for earthquake victims in Myanmar](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/d4949a0510ba40af93a15359b5450df2)

![[Photo] President Luong Cuong and King Philippe of Belgium visit Thang Long Imperial Citadel](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/cb080a6652f84a1291edc3d2ee50f631)

![[Photo] Myanmar's capital in disarray after the great earthquake](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/1/7719e43b61ba40f3ac17f5c3c1f03720)

Comment (0)