INVESTMENT IN MODERN MACHINERY

As a company specializing in the production of machinery and auxiliary components in cashew processing and an enterprise that designs, manufactures and distributes the most modern cashew nut splitting machine system in Vietnam, Dai Hoang Kim Binh Phuoc Automation Machinery Manufacturing Joint Stock Company (Dai Hoang Kim Company), Phuoc Tan village, Binh Tan commune, Phu Rieng district, is also one of the few enterprises that do not export technology abroad. General Director of the company Vu Thi Ngoc Diem said: With the motto "Building core values for the community", Dai Hoang Kim Company invested in more than 100 modern machines and equipment to produce and assemble the cashew nut shell cutting and separating equipment system. Outstanding in the automatic production process, in 2024 the company achieved a revenue of about 180 billion VND.

Dai Hoang Kim Company applies the most modern and advanced machinery on the market to produce cashew shell separation system equipment.

Dai Hoang Kim Company applies the most modern and advanced machinery on the market to produce cashew shell separation system equipment.

With a modern closed system, high-tech machinery and a team of design engineers and skilled workers, Dai Hoang Kim Company's production process has shortened production time, increased productivity and automated the cashew shelling process. The advantage of this equipment system is to help cashew processing enterprises increase profits and reduce costs in the production process. Producing 8-knife splitters with a capacity of 8 hours, Dai Hoang Kim Company's cashew splitters reach 1-1.2 tons and a set of machines can be equipped with up to 4 heads.

Mr. Vu Van Binh, Head of Quality Assurance Department, Dai Hoang Kim Company shared: The company's production line equipment meets diverse customer tastes. The company provides cashew nut shelling machines for private customers, from households that peel small quantities of cashew nuts to businesses that specialize in processing and producing large-capacity cashew nuts.

ADVANTAGES OF PATENTS

Owning a patent for a useful solution for the cashew processing system since 2019, Dai Hoang Kim Company has invested in technology to automate the production process and expand the factory scale with a capital of hundreds of billions of VND.

With the advantage of being a young enterprise in the era of industry 4.0, Dai Hoang Kim Company has pioneered the production of a system of equipment for cutting and separating hard shells of cashew nuts with the advantage of separating cashew nuts to get the kernel with the lowest rate of broken nuts and oil seeds. Applying modern machinery technology helps the company reduce labor, high productivity, optimize production costs, reduce prices, and increase competitiveness. In 2024, the company's equipment system was recognized as one of 32 typical rural industrial products at the provincial level and was recognized as a typical rural industrial product in the Southern region.

Financial Director of Vietnam Cashew Processing Technology Joint Stock Company (CPT CORP), Phu Rieng District, Ho Tuan Hung said: Every day, splitting about 100 tons of raw cashews, CPT CORP has used the cashew cutting and shelling equipment system of Dai Hoang Kim Company and achieved high efficiency. Nearly 5 years of using the cashew cutting and shelling equipment system has helped CPT CORP save time, labor, production costs and gain high profits. With a system of 12 continuously connected splitters and classified by size, the company's production process has met orders in a timely manner, especially the products are even, beautiful, with a very low rate of broken, cracked and missing nuts.

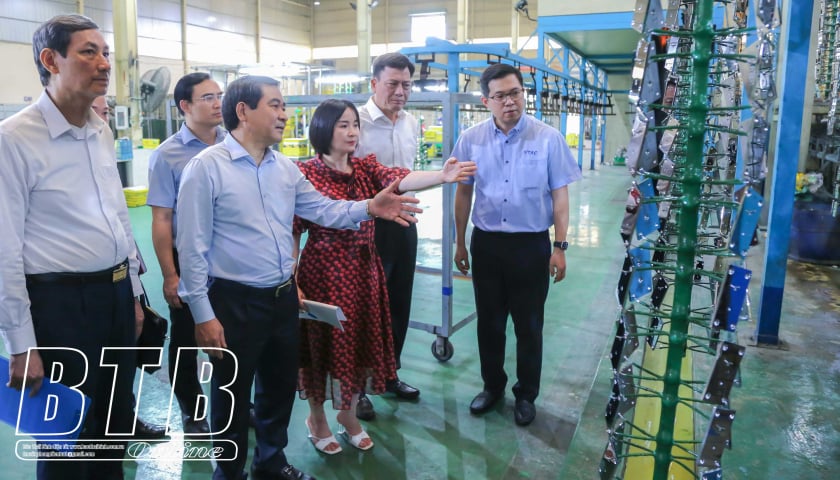

CPT Company CORP (district) Phu Rieng) uses Dai Hoang Kim cashew cutting and shelling equipment system to help Save time, labor, production costs and earn high profits

CPT Company CORP (district) Phu Rieng) uses Dai Hoang Kim cashew cutting and shelling equipment system to help Save time, labor, production costs and earn high profits

Also a company specializing in researching, designing, manufacturing and distributing auxiliary components in the cashew processing industry, for nearly 7 years, Gia Bao Mechanical Production - Trade - Import-Export Company Limited (Gia Bao Company), Phuoc Long town has continuously improved and enhanced the quality of equipment and machinery to meet the production needs of domestic and foreign cashew processing companies and enterprises. The new technology cashew shelling machine with a compact design including 16 cutting blades of the unit has been granted an exclusive patent and has been purchased and used by many companies.

Gia Bao Company's new technology 16-blade cashew shelling machine helps to reduce loss rate, separation capacity reaches maximum 10 tons/day, broken cashew nut rate reduces from 7% to 3%.

Gia Bao Company's new technology 16-blade cashew shelling machine helps to reduce loss rate, separation capacity reaches maximum 10 tons/day, broken cashew nut rate reduces from 7% to 3%.

After more than 2 years of research, production and successful assembly of a new technology cashew shelling machine with 16 blades, Gia Bao Mechanical's machines are currently being used at many large and small cashew processing facilities in and outside the province and exported to Cambodia and China. Director of Gia Bao Company Nguyen Van Lien said: Gia Bao Mechanical has registered intellectual property for 7 types of machines that the unit is producing. All machine lines are self-researched, produced in detail and assembled by the unit.

CONTINUOUS INNOVATION

Director of Gia Bao Company Nguyen Van Lien emphasized: As a company specializing in designing, manufacturing and distributing auxiliary components in the cashew processing industry, Gia Bao is always proactive in researching and inventing cashew shelling machines. From the production of 8 and 10-knife machines on the market, in 2024, the company researched and produced a new technology cashew shelling machine line consisting of 16 blades with a direct gear drive mechanism, low loss rate, and a maximum separation capacity of 10 tons/day. The special feature of this machine line is that the rate of broken cashew nuts is reduced from 7% to 3%.

Research and development of technological solutions have contributed to maintaining and strengthening the strengths of the cashew processing industry, creating sustainable value chains for businesses and the community.

Research and development of technological solutions have contributed to maintaining and strengthening the strengths of the cashew processing industry, creating sustainable value chains for businesses and the community.

Similarly, Dai Hoang Kim Company also continuously optimizes the products being manufactured, while researching and developing more advanced, exclusive technology products to serve the domestic cashew processing industry. Head of Design Department, Dai Hoang Kim Company Le Minh Hai added: The company applies CNC machines, which are the most modern and advanced machines on the market to produce cashew shell separation system equipment. The company continuously makes improvements and innovations according to customer feedback to make the products more and more perfect and accurate. It is from the feedback of partners that helps the company to produce more and more good and quality products.

The innovations and improvements of companies and enterprises have been contributing to maintaining and consolidating the strengths of the cashew processing technology industry, creating a sustainable value chain for enterprises as well as for the community, making the Vietnamese cashew production and processing industry confident in its presence in demanding markets around the world.

Source: https://baobinhphuoc.com.vn/news/4/169703/giai-phap-cong-nghe-cai-tien-quy-trinh-san-xuat

![[Photo] National Assembly Chairman Tran Thanh Man meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/4e8fab54da744230b54598eff0070485)

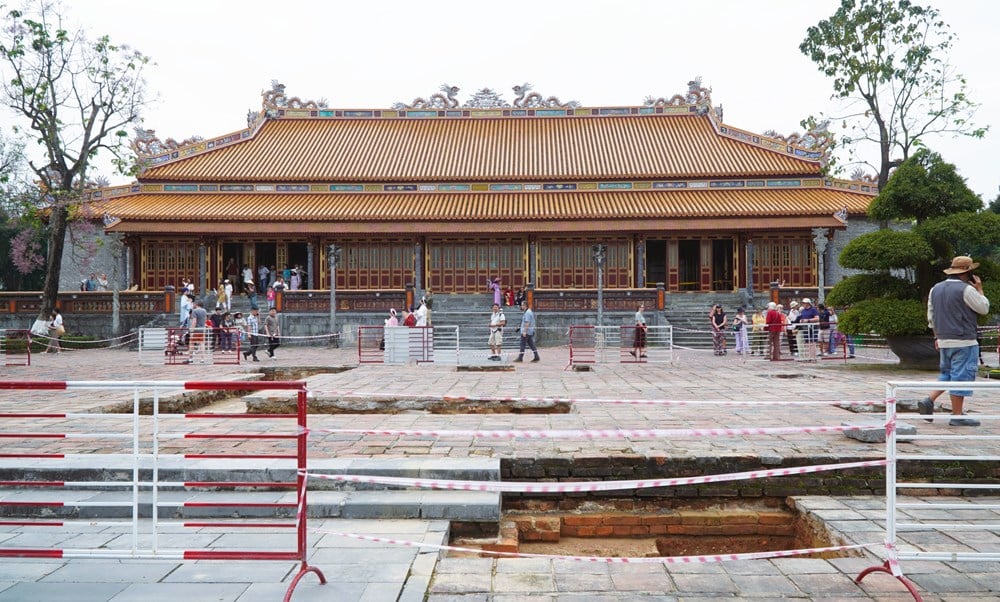

![[Photo] Ceremony to welcome General Secretary and President of China Xi Jinping on State visit to Vietnam](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/5318f8c5aa8540d28a5a65b0a1f70959)

![[Photo] Prime Minister Pham Minh Chinh meets with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/893f1141468a49e29fb42607a670b174)

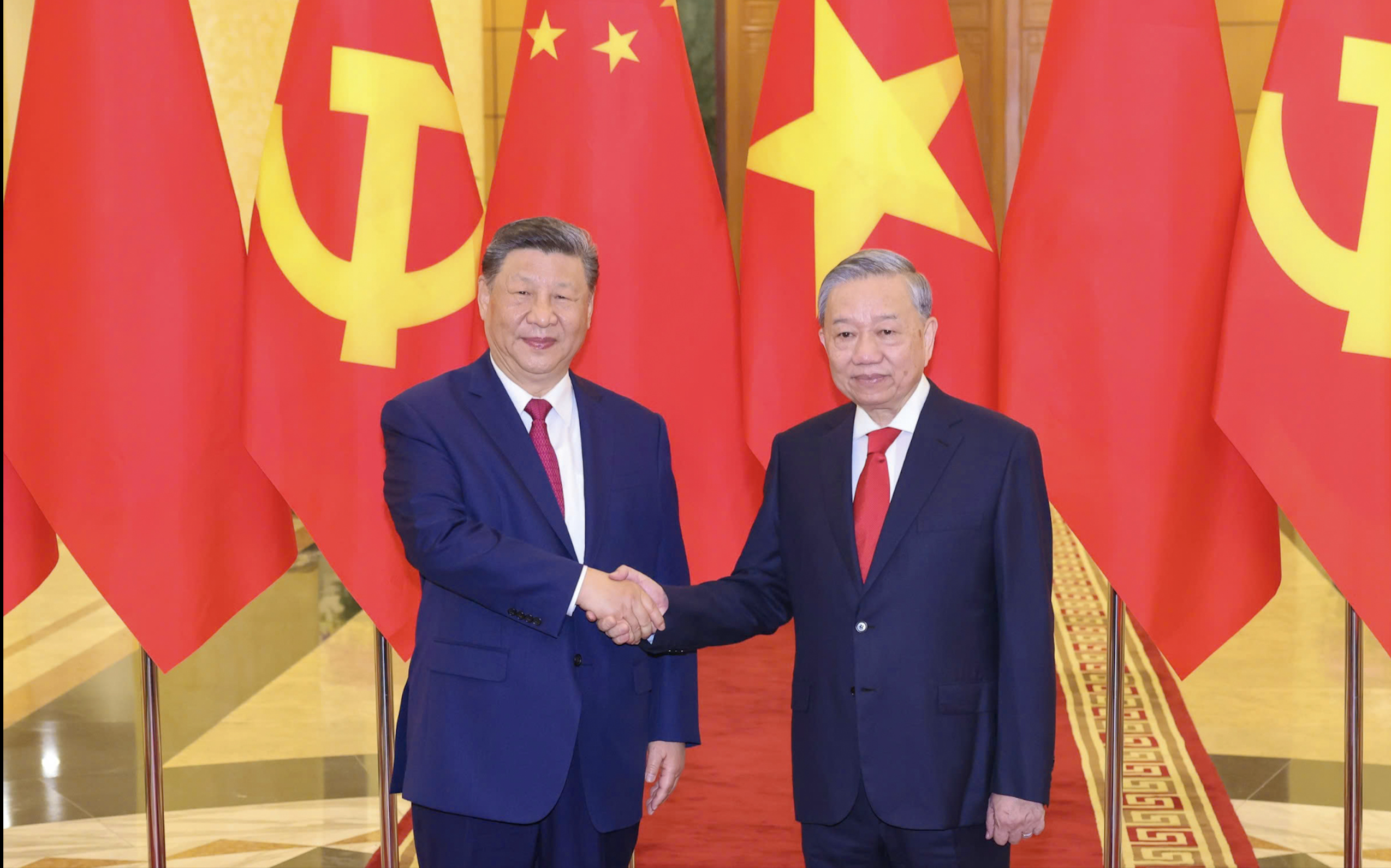

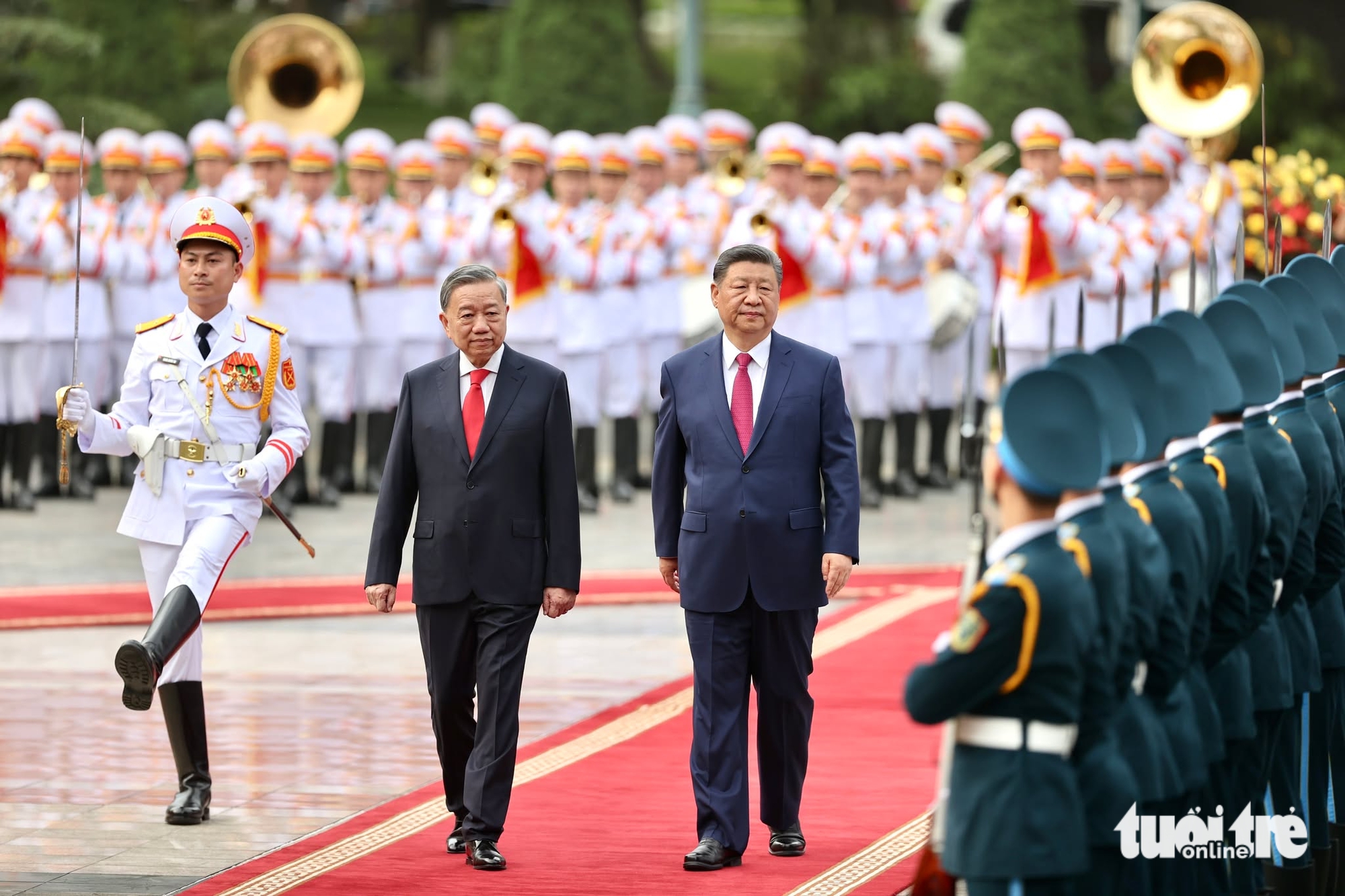

![[Photo] General Secretary To Lam holds talks with General Secretary and President of China Xi Jinping](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/14/b3d07714dc6b4831833b48e0385d75c1)

Comment (0)