At Acecook Vietnam, the “4M” management rule has become the guiding principle for the company to rise to the leading position in the instant noodle industry, building trust over decades with consumers.

Maintaining and improving product quality to meet the increasingly diverse needs of consumers is considered a big challenge, requiring businesses to focus on every aspect, no matter how small, throughout the process of researching, developing and bringing products to market. At Acecook Vietnam, the company thoroughly applies the “4M” management rule, as a guideline in the production process, to ensure the highest quality for all of the company’s products.

“Material” - raw materials are selected from the source

Raw materials are the core of product quality. To ensure input quality, Acecook Vietnam has continuously improved the standards of raw material selection and management through the establishment of a comprehensive and strict quality system.

The company has established selective criteria according to domestic and international food laws; cooperated with reputable suppliers. At the same time, all suppliers are required to commit to not using additives not listed, not irradiated, not genetically modified (NON GMO)... and not causing harm to the environment.

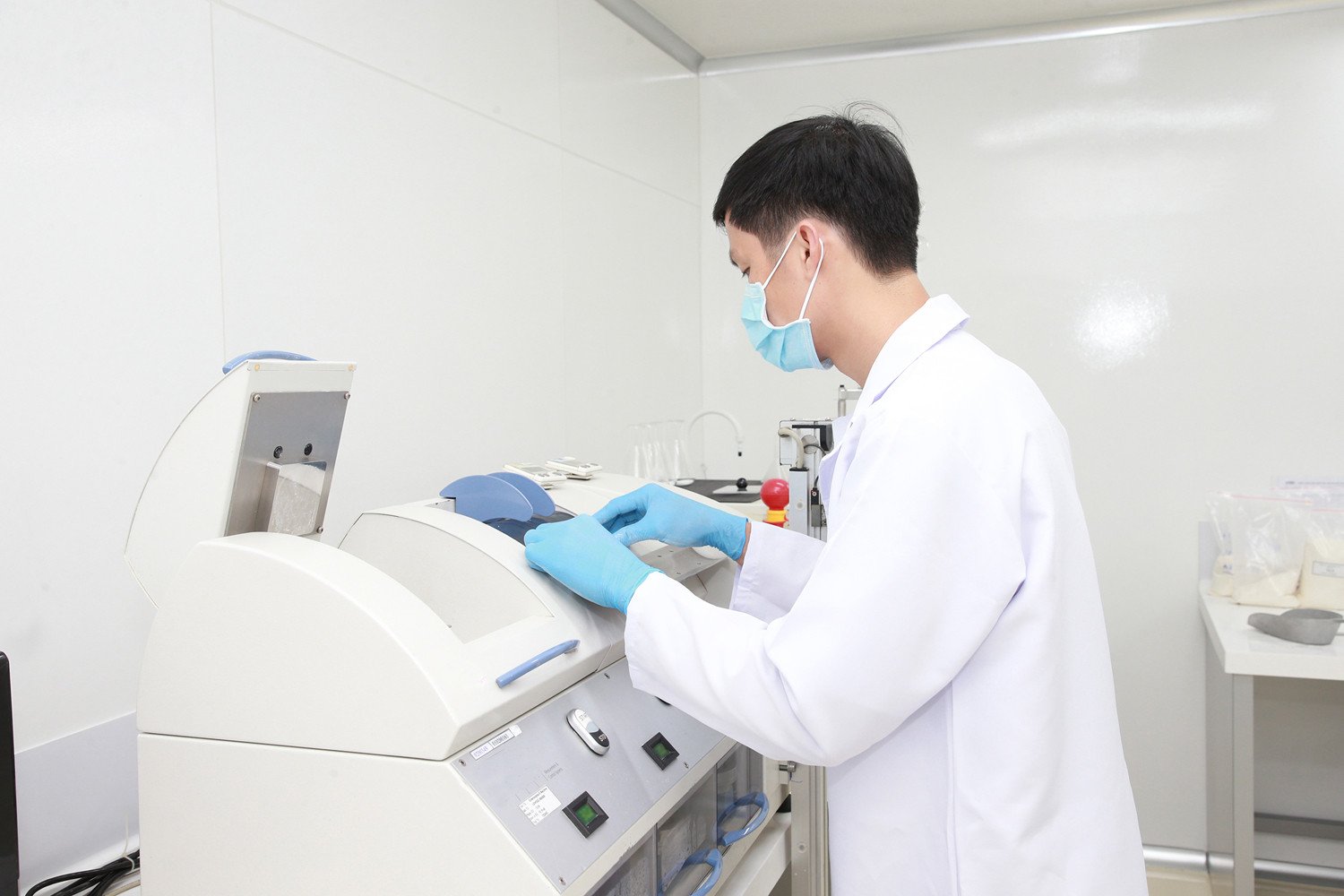

To control, Acecook owns a modern technology laboratory, meeting international standards ISO/IEC 17025 with an investment cost of millions of USD, managed by more than 30 highly qualified specialists, regularly trained at prestigious domestic and international analysis centers.

“Machine” - Japanese technology brings consistent quality

Acecook Vietnam provides consistent quality products thanks to the application of advanced technology from Japan and a highly automated factory system. The company currently owns 11 factories and 6 branches nationwide such as Ho Chi Minh City, Binh Duong, Vinh Long, Da Nang, Hung Yen and Bac Ninh.

According to Acecook Vietnam, each of these factories has an investment cost of tens of millions of USD and is transferred Japanese technology, with an automation rate of over 90% and an average production capacity of about 600 noodle packages/minute/line. This helps the company serve consumers with more than 3.5 billion products/year at stable prices.

In addition, Acecook Vietnam is also building a "super factory" with an investment scale of up to 200 million USD in Vinh Long area, in Hoa Phu industrial park, on an area of 11 hectares, including 2 production workshops and offices.

“Method” - cultural integration for success

When bringing instant noodles to the Vietnamese market, Acecook chose a different path by not imposing Japanese recipes but instead focusing on Vietnamese flavors. The tastes of Vietnamese consumers, whether from the North or the South, are respected and developed.

With the “classic” sour and spicy recipe, combining the essence of the flavors of onions, garlic, chili, herbs... suitable for the taste of all 3 regions, for many years, the “Hao Hao” brand has been the best-selling instant noodle product in Vietnam.

Acecook's "localization" strategy is also reflected in products with "inspiration" taken from the traditional culinary treasure and using diverse and unique ingredients such as Hang Nga vermicelli with fish sauce flavor, Nhip Song noodles with Nam Vang noodles flavor, De Nhat pho with crispy beef brisket...

“Man” - people are the key factor in quality

At Acecook Vietnam, people are the core element in the “4M” strategy. The company currently has more than 6,000 employees with more than 20 Japanese experts holding leadership and senior specialist positions. As a Japanese enterprise, Acecook's management philosophy is oriented towards an inclusive, friendly and cohesive working culture based on the “3 H” (Happy) mission: Happiness for consumers (and partners), happiness for employees (and their families), happiness for society.

Employees at Acecook Vietnam are always given the opportunity to work with passion and pride to create good, safe and delicious products for customers. The company's employees are provided with the best working environment through competition programs, rewards and worthy benefits.

Moreover, Acecook Vietnam always spends a large amount of money to invest in domestic and foreign training for potential employees; to build and nurture a sense of responsibility, carefulness, and thoughtfulness for the staff. From here, each person clearly understands their role and value in helping the company fulfill its mission.

Acecook's success comes not only from quality, but also from consumer trust.

A representative of Acecook Vietnam shared: “Each product is the result of a process from raw material research to automated production lines and strict quality standards. Along with that is the company's passion and love over the past 3 decades. Continuing to move forward on the journey of bringing happiness through cuisine, Acecook is moving towards a future of sustainable development and expanding contributions to the whole society.”

Ngoc Minh

Source: https://vietnamnet.vn/acecook-viet-nam-quy-tac-quan-ly-4m-2346643.html

![[Photo] Special relics at the Vietnam Military History Museum associated with the heroic April 30th](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/3/a49d65b17b804e398de42bc2caba8368)

![[Photo] Moment of love: Myanmar people are moved to thank Vietnamese soldiers](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/3/9b2e07196eb14aa5aacb1bc9e067ae6f)

![[Photo] General Secretary To Lam receives Japanese Ambassador to Vietnam Ito Naoki](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/3/3a5d233bc09d4928ac9bfed97674be98)

Comment (0)