The robot, developed by the University of Liverpool's Robotiz3d company, can repair cracks and prevent potholes from getting bigger, saving millions of dollars in road repair costs every year.

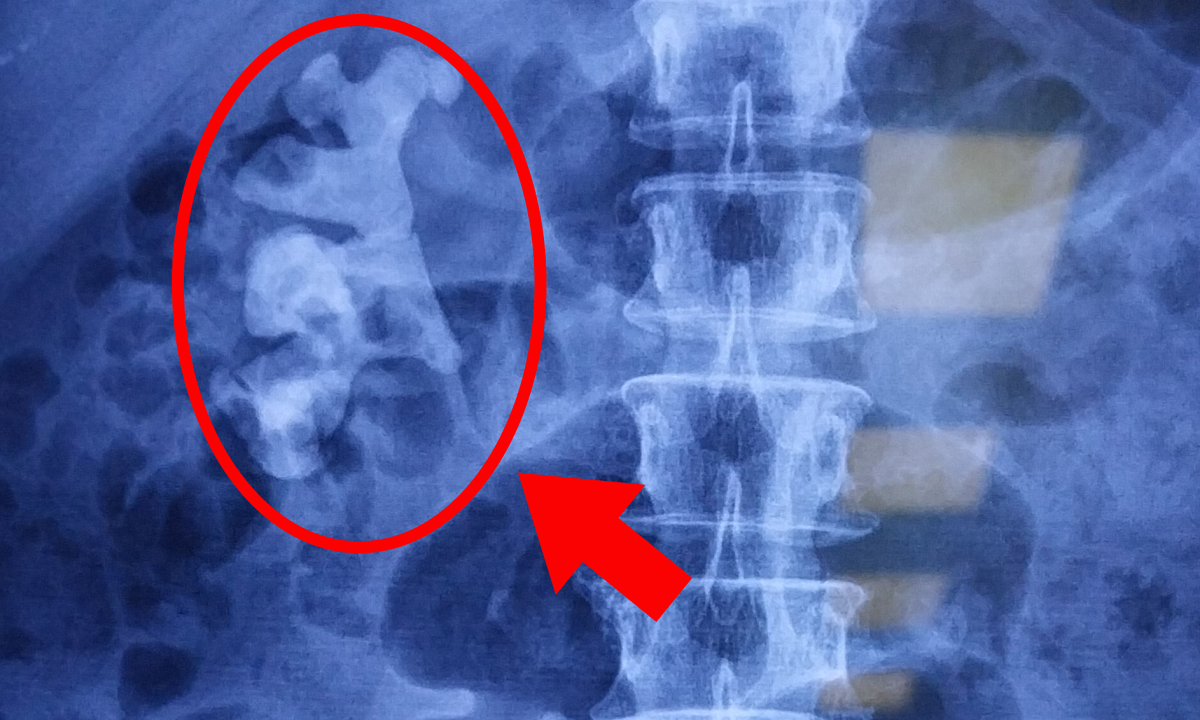

Operation of the ARRES PREVENT road repair robot. Photo: Robotiz3d

The world's first road repair robot will be on the streets of Hertfordshire, England, in the next few months to test autonomous repair technology, the Mail reported on January 11. The robot, called ARRES PREVENT (Autonomous Road Repair System), uses artificial intelligence to automatically detect, classify and fill cracks. If the trial is successful, the robot will be able to proactively detect and patch cracks before they become too large to quickly fix. This could make road maintenance cheaper, more efficient and faster than using human labor.

ARRES PREVENT is a collaboration between Robotiz3d and experts at the University of Liverpool and the Hertfordshire Highways Engineering Council. Robotiz3d itself is a technology company of the University of Liverpool, funded by the University's Enterprise Investment Fund.

Started in 2020, the robot is currently the world’s only autonomous road repair vehicle. While it’s still in its early testing stages, it will be operating on real roads later this year. It will be released to autonomously search and repair damage on Hertfordshire’s roads.

A Hertfordshire County Council spokesperson said the robot would support their existing workforce. "Our intention is to use the AI robot alongside humans, not to replace them. It will autonomously find and patch cracks on the road while our technicians work elsewhere, helping to prevent larger potholes in the future and reducing disruption to public transport," the spokesperson said.

The robot works by patrolling roads and scanning the surface with a camera. Using AI, it can detect depressions in the road surface and classify them as potholes or cracks. Once it identifies surface damage, it can decide whether to repair it immediately or add it to its checklist for later. If it decides to repair it, it can inject a filler into the crack to prevent water from causing further damage. While the robot can’t fill in large potholes, Robotiz3d says its goal is to prevent them from forming in the first place.

Potholes form from small cracks in the road surface caused by aging, bad weather, or other forms of erosion. As the cracks form, water seeps into them and causes them to grow. In the winter, the water freezes into ice and expands, causing the cracks to widen. Many of the chunks of asphalt are then plowed away by passing vehicles.

Because of the cold, wet weather in the UK, rainwater easily flows into potholes, deepening them until they are large enough to cause damage to vehicles. Fixing potholes can be extremely expensive. The UK government recently spent $3.6 billion to fix roads in the east, south-east, south-west and London alone. Robotiz3d estimates that UK drivers pay $2.20 in pothole-related costs each year.

According to Robotiz3d, their automated solution is 90% cheaper than human labor, which could save millions of pounds over the years. The average time to repair a pothole is 15 months in the UK. Since the robot doesn’t need to rest, it can work full-time to constantly monitor and repair damage to the road surface. By switching to a robot, Robotiz3d estimates it can make repairs 70% faster than humans.

An Khang (According to Mail )

Source link

![[Photo] Opening of the 11th Conference of the 13th Party Central Committee](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/f9e717b67de343d7b687cb419c0829a2)

![[Photo] April Festival in Can Tho City](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/bf5ae82870e648fabfbcc93a25b481ea)

![[Photo] Unique folk games at Chuong Village Festival](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/cff805a06fdd443b9474c017f98075a4)

![[Photo] Prime Minister Pham Minh Chinh commends forces supporting Myanmar in overcoming earthquake consequences](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/e844656d18bd433f913182fbc2f35ec2)

Comment (0)