Entrepreneur Anh Duong, Co-founder of AirX Carbon: The journey to commercialize negative carbon

By producing and commercializing carbon-negative products, raw materials, and materials, businessman Anh Duong and AirX Carbon have opened up a promising direction to contribute to Vietnam's goal of protecting the environment and achieving net zero emissions by 2050.

|

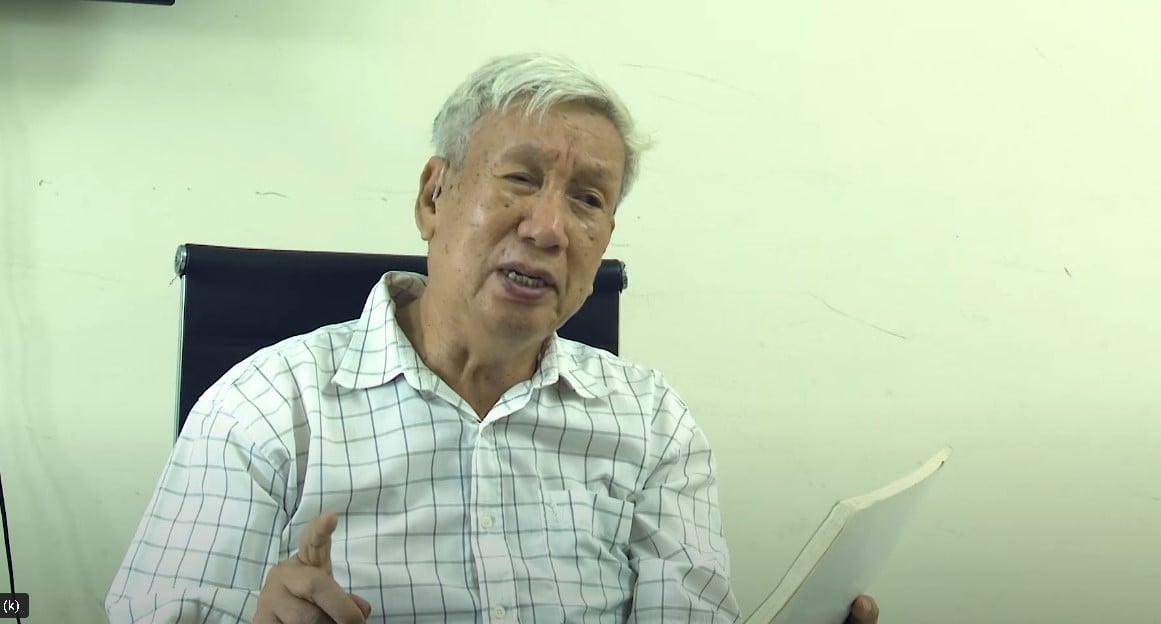

| Businessman Anh Duong (front row, right), Co-founder of AirX Carbon. |

“Tuition” for starting a business

Before starting AirX Carbon, Mr. Anh Duong and his colleagues had implemented a project to produce and trade shoes, sandals, and masks from coffee grounds. At that time, Mr. Duong’s team had to import biological materials from abroad for production. From there, he realized the great potential of the biological materials market.

In 2020, Mr. Duong and his colleagues founded AirX Carbon, turning to research, production, and development of biological materials. Recalling this period, Mr. Duong shared that because biological materials, especially negative carbon biological materials, are quite new in Vietnam, the AirX Carbon team had to pay a lot of "tuition".

“Sometimes, we make a raw material similar to that of a foreign country, but we cannot put it into production domestically because Vietnam does not have the machinery to process that type of material. Once, we ordered a sample of raw material, but the partner delivered the wrong product. We did not know, so we kept doing it but could not produce the finished product,” Mr. Duong said.

Due to the lack of machinery and facilities for research, AirX Carbon has cooperated with a number of universities to accelerate research to produce products. However, the facilities at research institutes are only at the laboratory scale, and to put them into industrial production, much more is needed. However, the difficulties did not discourage Mr. Duong and his team.

Open opportunities

The main product that AirX Carbon provides is carbon negative raw material derived from plant-based agricultural by-products for businesses to create their own bioplastic products and materials, replacing traditional petroleum-based plastics.

Carbon negative simply means removing CO2 from the atmosphere or sequestering more CO2 than is emitted. AirX Carbon uses agricultural by-products such as coffee grounds, bagasse, coconut fiber, cocoa husks, bean dregs, etc., without using food crops. The company then converts all the carbon isotopes (C14) found in the biomass, through a complex material synthesis process, to create plant-based plastic.

“Because trees absorb CO2 through photosynthesis and store carbon in their structure, when reusing ‘discarded’ structural parts, such as coffee grounds or sugarcane stalks, to produce bio-composite materials, AirX Carbon can ensure that the carbon previously absorbed by the trees will be retained, not entering the atmosphere and remaining throughout the entire life cycle of the product. In some special bio-materials, the carbon element is permanently locked and does not return to CO2,” Mr. Duong explained.

Similarly, by combining multiple feedstocks during production, AirX can be carbon negative due to its high bio-content and lower energy requirements than producing new plastic from virgin materials. At the end of its life, the bio-based plastic can be recycled to create a new form of material, ensuring that carbon is continuously captured and recirculated within the material. This not only promotes a circular economy, but also helps to limit carbon emissions.

AirX Carbon has a range of bioplastics, from low carbon storage (0.841 tonnes of carbon per tonne of plastic) to high carbon storage (1.5 tonnes of carbon per tonne of feedstock). The company is perfecting a new bioplastic that can store up to 3.5 tonnes of carbon per tonne of feedstock.

In 2023, AirX Carbon will launch the world's first carbon-negative material from coffee grounds. Mr. Duong is proud that there are currently about 3 or 4 units that can produce carbon-negative material from coffee grounds, but AirX Carbon is the only unit that can commercialize this material.

The market for biomaterials and carbon negative materials is very open, so the opportunity for AirX Carbon is huge. “The green economic trend, Net Zero is pushing businesses to transform. With products that keep up with the trend, we have received a lot of attention,” said Mr. Duong.

Sharing with Dau Tu Newspaper, Mr. Anh Duong said that in the next 12 months, AirX Carbon will officially complete and put the factory in Long An into operation with a capacity of about 500 tons of raw materials/month. Notably, the company has customers to purchase output.

Typically, in a cooperation project with a Japanese partner, AirX Carbon has utilized coffee grounds/bamboo to create bio-based granules to replace oil-based products with a bio-content of more than 51%. In the Japanese market, when a product has a bio-content of more than 51%, it is not considered plastic and enjoys many preferential policies. This has helped AirX Carbon reach a pre-purchase agreement to supply several hundred tons of bio-materials with a Japanese partner.

Currently, AirX Carbon's main source of revenue is still from selling final products made from carbon-negative biomaterials, such as cups, glasses, furniture, etc. "The carbon-negative material market needs another 5 to 7 years to become more favorable. But now, the final products are easier to bring to market and generate better sales. We use this profit to continue investing, serving the main goal of producing and supplying carbon-negative biomaterials," Mr. Duong shared.

Source

![[Photo] Phuc Tho mulberry season – Sweet fruit from green agriculture](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/1710a51d63c84a5a92de1b9b4caaf3e5)

![[Photo] Prime Minister Pham Minh Chinh chairs meeting to discuss tax solutions for Vietnam's import and export goods](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/19b9ed81ca2940b79fb8a0b9ccef539a)

![[Photo] Unique folk games at Chuong Village Festival](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/4/10/cff805a06fdd443b9474c017f98075a4)

Comment (0)